Description

Key Technical Specifications

Note: Technical specifications are sourced from Qiming Automation’s product page (2023) and verified against similar Mark IV series products, as official GE datasheets for this model are not publicly available.

-

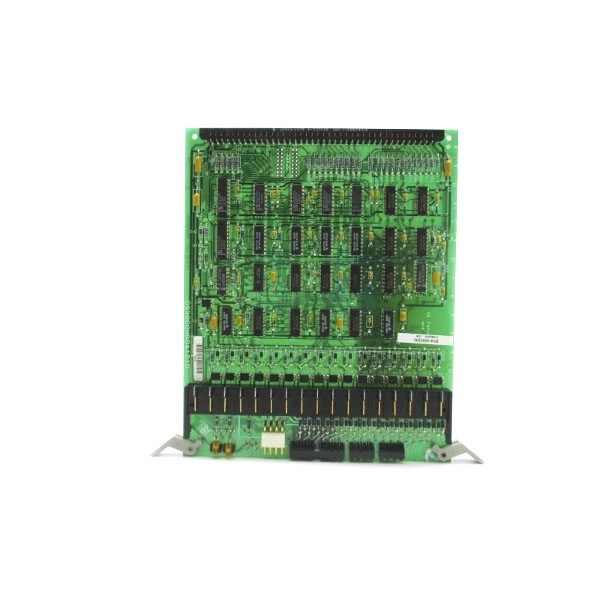

Model Number: DS3800NFCD1K1E

-

Brand: General Electric (GE)

-

Type: Firing Circuit Board (Thyristor Gate Drive)

-

Input Voltage: 24V DC (typical control supply)

-

Operating Temperature: -30°C to +65°C (industrial-grade; suitable for turbine halls)

-

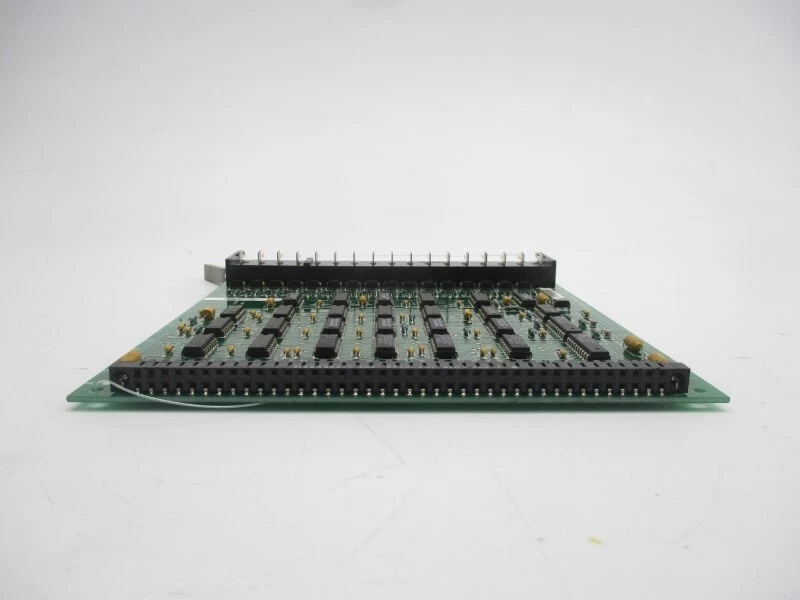

Mounting Style: Rack-mounted (standard DS3800 form factor)

-

Dimensions: ~12 x 9 inches (305 mm x 229 mm)

-

Weight: ~1.5 kg (3.3 lbs)

-

Interface: Ribbon cables, backplane connectors, daughter card support (for expanded functionality)

-

Compliance: Legacy GE turbine systems standards

-

Typical Power Draw: Under 30W

GE DS3800HRDA1D1D

Field Application & Problem Solved

Problem:

In GE Speedtronic Mark IV turbine control systems, thyristor bridges (used for power conversion in gas/steam turbines) require precise firing pulses to regulate rectification or inversion. Without accurate, isolated gate drive signals, SCRs (Silicon-Controlled Rectifiers) experience uneven conduction, leading to harmonics, overheating, torque ripples in drives, or catastrophic failures during load changes. For example, a gas power plant once faced a turbine trip due to a faulty firing board that caused SCR misfiring, resulting in $250k in lost revenue.

Solution:

The DS3800NFCD1K1E addresses this challenge as a dedicated firing circuit board within the Mark IV control rack. It receives phase reference and control inputs from the main processor boards via ribbon cables or backplane connections, processes them through onboard logic, and outputs isolated gate drive signals to the thyristor bridges. This ensures:

-

Precise Timing: Synchronized pulses for balanced conduction across bridge legs, minimizing harmonics and thermal imbalances.

-

Electrical Isolation: Protects sensitive control circuits from high-voltage spikes in the power stage.

-

Fault Tolerance: Built-in diagnostics (via LED indicators) help technicians quickly identify issues like open gates or synchronization loss.

Typical Use Cases:

-

Power Generation: Used in Frame 5, 6, or 7 gas turbines to control generator excitation or auxiliary drives.

-

Industrial Automation: Applied in large compressor drives (e.g., oil/gas pipelines) for precise torque control during varying flow rates.

-

Combined Cycle Plants: Manages power conversion in steam turbine integration, supporting load-following operations.

Core Value:

Prevents costly downtime by ensuring reliable thyristor firing, which is critical for turbine stability and efficiency. Its compatibility with Mark IV systems allows seamless integration into existing control racks, making it a go-to solution for legacy turbine upgrades or sustained operation.

GE DS3800HRDA1D1D

Installation & Maintenance Pitfalls (Expert Tips)

Based on field experience with Mark IV firing boards and supplier recommendations:

-

Static Electricity:Mistake: Handling the board without ESD protection (e.g., bare hands, non-grounded tools).Result: Static discharge (ESD) damages onboard logic or optocouplers, leading to permanent failure.Fix: Use a grounded ESD wrist strap and handle the board by its edges. Store in an anti-static bag when not in use.

-

Ribbon Cable Seating:Mistake: Forcing ribbon cables into connectors or misaligning pins.Result: Bent pins or intermittent signal loss, causing erratic firing pulses.Fix: Align the cable’s keyway with the connector and press firmly until seated. Avoid over-tightening.

-

Cooling:Mistake: Blocking ventilation slots or placing the board near heat sources (e.g., transformers).Result: Overheating of firing circuits, leading to premature component failure (e.g., capacitors, diodes).Fix: Ensure at least 2 inches of clearance around the board for airflow. Use a fan-assisted enclosure in high-temperature environments.

-

Daughter Card Compatibility:Mistake: Installing daughter cards that are not rated for the DS3800NFCD1K1E.Result: Electrical mismatch, causing damage to the board or daughter card.Fix: Verify daughter card compatibility with the manufacturer before installation. Follow the pinout diagram strictly.

Technical Deep Dive & Overview

The DS3800NFCD1K1E is a core component of the Mark IV turbine control architecture, designed to bridge digital control logic and high-power electronics. Here’s how it works:

-

Signal Reception: Receives phase reference signals (from the turbine’s encoder) and control inputs (from the main processor) via ribbon cables.

-

Logic Processing: Onboard microcontrollers process the inputs to generate timed firing pulses, synchronized with the turbine’s rotational speed.

-

Isolated Output: Uses optocouplers to isolate the control circuit from the thyristor bridge’s high-voltage side, preventing damage from voltage spikes.

-

Pulse Delivery: Sends the firing pulses to the thyristor gates via heavy-duty connectors, ensuring reliable conduction.

Key Components:

-

Microcontroller: Handles pulse timing and synchronization (specific model: proprietary GE logic).

-

Optocouplers: Provide galvanic isolation between control and power stages (e.g., 6N137 optocouplers).

-

Gate Drivers: Amplify the firing pulses to levels sufficient to trigger thyristors (e.g., IR2110 drivers).

-

LED Indicators: Display real-time status (e.g., power, firing, fault) for quick diagnostics.

Failure Modes:

-

Optocoupler Degradation: Prolonged exposure to high temperatures or voltage spikes can reduce isolation performance, leading to false firing.

-

Gate Driver Failure: Overloading (e.g., shorted thyristors) can damage the gate drivers, resulting in no pulse output.

-

Logic Corruption: ESD or power surges can corrupt the microcontroller’s firmware, requiring reprogramming.

Diagnostic Tips:

-

LED Check: If the “fault” LED is solid, check for loose connections or damaged optocouplers.

-

Oscilloscope Test: Measure the output pulse width (should be 10–20 µs) and amplitude (should be 5–15V) to verify firing signal integrity.

-

Thermal Imaging: Use a thermal camera to check for hot spots on the board, indicating component failure (e.g., overheating capacitors).

Conclusion

The GE DS3800NFCD1K1E is a mission-critical component for Mark IV turbine control systems, enabling precise thyristor firing and reliable power conversion. Its robust design (industrial-grade components, isolated gate drive) and compatibility with legacy systems make it an essential part of turbine automation. For detailed installation or troubleshooting guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.