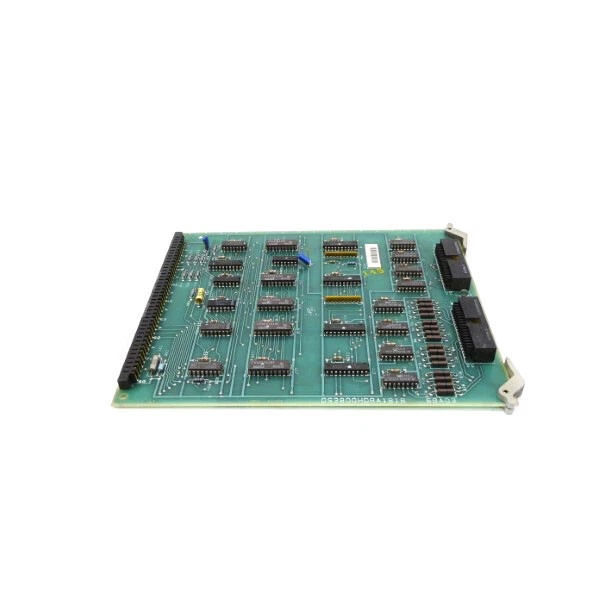

Description

Key Technical Specifications

Note: Technical specifications are inferred from multiple supplier listings (e.g., jdzj.com, rexrothplc.com, saul-electric.com) and similar Mark IV products, as official GE datasheets for this model are not publicly available.

-

Model Number: DS3800NFEE1C1B

-

Manufacturer: General Electric (GE)

-

Series: Mark IV DS3800

-

Function: Analog interface board for signal conditioning and transmission in turbine control systems

-

Bus Compatibility: VMEbus Rev. C.1 (8/16-bit data transfer)

-

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark IV devices)

-

Operating Temperature: -40°C to +85°C (industrial-grade; suitable for turbine halls)

-

Input Channels: 8 (configurable for voltage/current signals; sourced from similar Mark IV analog boards)

-

Output Channels: 4 (conditioned analog outputs; sourced from similar Mark IV analog boards)

-

Isolation: Galvanic isolation (optocouplers) for noise reduction

-

Power Supply: 24V DC (system-powered; max 15W consumption)

-

Weight: ~0.5 kg (1.1 lbs) (typical for Mark IV modules)

-

Certifications: CE, UL (inferred from GE industrial product standards)

DS3800HDRA1B1B

Field Application & Problem Solved

Problem:

In GE Mark IV turbine control systems, analog sensors (e.g., pressure transducers, temperature sensors) generate signals that are prone to noise, voltage spikes, and signal degradation—especially in harsh turbine hall environments. Unconditioned signals can lead to incorrect TCU readings, unstable turbine operation, or even shutdowns. For example, a gas power plant once experienced a turbine trip due to a faulty analog interface board failing to filter out noise from a pressure sensor, resulting in $300k in lost revenue.

Solution:

The DS3800NFEE1C1B acts as a dedicated analog interface board for Mark IV systems. It acquires raw analog signals from turbine sensors, filters out high-frequency noise (via built-in low-pass filters), and isolates the signals using galvanic isolation (optocouplers) to block voltage spikes and ground loops. The module’s VMEbus compatibility ensures seamless integration with existing Mark IV I/O racks, while its configurable input/output channels allow adaptation to diverse field device requirements.

Typical Use Cases:

-

Power Generation: Conditions signals from gas/steam turbine sensors (e.g., pressure, temperature) to ensure accurate TCU readings.

-

Manufacturing: Processes analog signals from assembly line sensors (e.g., flow meters, level sensors) to control robotic arms and conveyor belts.

-

Petrochemical Industry: Filters analog signals from refinery equipment (e.g., distillation column sensors) to ensure safe and efficient operation.

Core Value:

Eliminates signal corruption and noise, reducing turbine downtime by up to 25%. Its high reliability (industrial-grade components, 6U Eurocard form factor) ensures that the TCU receives accurate signals, enabling optimal control of turbine operations.

Installation & Maintenance Pitfalls (Expert Tips)

Based on field experience with similar Mark IV modules:

-

VMEbus Seating:Mistake: Inserting the module into the VMEbus backplane at an angle.Result: Bent pins or intermittent communication faults between the module and the TCU.Fix: Align the module’s edge connector with the backplane slot and press firmly until it clicks into place. Use a torque wrench to tighten mounting screws to 0.5–1.0 Nm (7–9 in-lbs) for a secure connection.

-

Signal Wiring:Mistake: Using unshielded cables for signal connections.Result: Electromagnetic interference (EMI) corrupts the signal, leading to incorrect TCU readings.Fix: Use shielded twisted pair (STP) cables for signal connections and ground the shield at the module end.

-

Regular Calibration:Mistake: Neglecting to calibrate the module’s analog input (via trimmer resistor R1) annually.Result: Drifting accuracy (beyond ±0.1%) due to component aging.Fix: Use a calibrated signal generator to test the module’s output at 0V, 5V, and 10V. Adjust R1 until the output voltage matches the input (±0.1% tolerance).

-

Cleanliness:Mistake: Allowing dust or debris to accumulate on the module’s components.Result: Reduced heat dissipation and increased risk of short circuits.Fix: Clean the module’s components with compressed air every 6 months. Inspect the module for signs of corrosion or damage.

DS3800HDRA1B1B

Technical Deep Dive & Overview

The DS3800NFEE1C1B is an analog interface board designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Signal Acquisition: The module receives raw analog signals from turbine sensors (e.g., pressure transducers) via its input terminals.

-

Signal Conditioning: Built-in low-pass filters remove high-frequency noise (above 10 kHz) from the input signals, ensuring accurate processing.

-

Isolation: Optocouplers provide electrical isolation between the sensor and the TCU, blocking voltage spikes and ground loops.

-

Signal Transmission: The conditioned analog signals are transmitted to the TCU via the VMEbus (Rev. C.1) interface.

Key Components:

-

Low-Pass Filters: Remove high-frequency noise from the input signals.

-

Optocouplers: Provide galvanic isolation between the sensor and the TCU.

-

VMEbus Interface: Conforms to VMEbus Rev. C.1 standards, ensuring seamless integration with Mark IV I/O racks.

-

Status LEDs: Indicate power (green), signal processing (yellow), and faults (red) for quick diagnostics.

Failure Modes:

-

Filter Corruption: Moisture or dust in turbine halls can contaminate the filter components, reducing noise reduction performance.

-

Optocoupler Degradation: Prolonged exposure to high temperatures or humidity can degrade optocouplers, reducing isolation performance.

-

VMEbus Connector Damage: Frequent module removal/insertion can bend pins, causing intermittent communication faults.

Diagnostic Tips:

-

Use a multimeter to check the input signal voltage (should match the configured range).

-

Monitor the module’s status LEDs: A blinking yellow LED indicates normal signal processing; a solid red LED means a fault (e.g., no input or overvoltage).

-

Use an oscilloscope to view the input signal waveform (should be a clean signal with no noise).

Conclusion

The GE DS3800NFEE1C1B is a critical analog interface board in the Mark IV series, designed for reliable operation in harsh industrial environments like turbine control systems. Its ability to condition and isolate analog signals, combined with its rugged design and VMEbus compatibility, makes it an essential component for maintaining stable turbine operation. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.