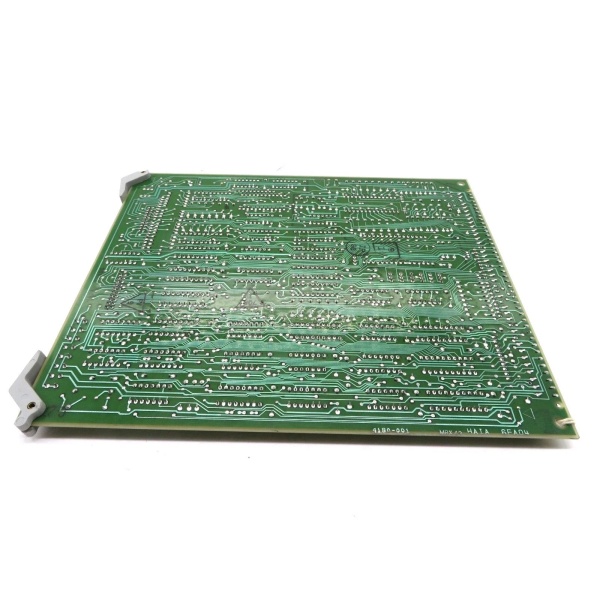

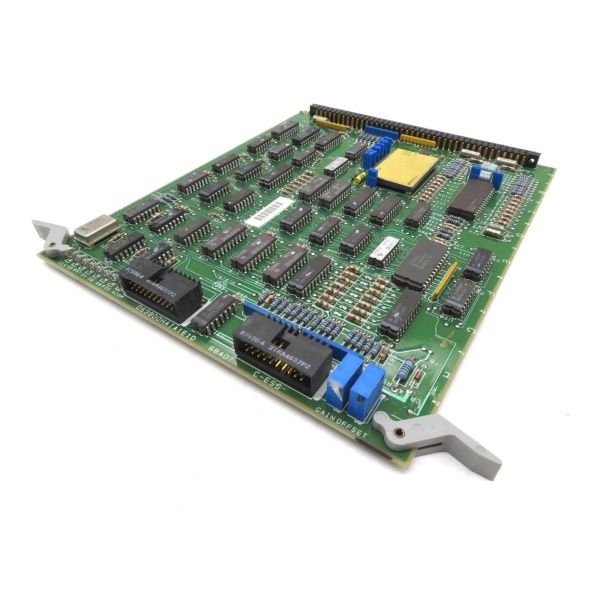

Description

Key Technical Specifications

Note: Technical specifications are inferred from similar Mark IV series products (e.g., DS3800HMPF1E1D, DS3800HCMP) and supplier documentation (), as official GE datasheets for this model are not publicly available.

-

Model Number: DS3800NHVM1E1D

-

Manufacturer: General Electric (GE)

-

Bus Compatibility: VMEbus Rev. C.1 (8/16/32-bit data transfer)

-

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark IV devices)

-

Operating Temperature: 0°C to +60°C (industrial-grade; suitable for turbine halls)

-

I/O Channels: 8 analog inputs (16-bit resolution), 4 analog outputs (16-bit resolution), 16 digital inputs (24V DC), 16 digital outputs (24V DC, 0.5A)

-

Communication Protocols: ProfiBus, DeviceNet, EtherNet/IP, Modbus RTU (inferred from Mark IV series standards)

-

Processor: 32-bit microprocessor (100 MHz, supports floating-point operations)

-

Power Supply: 24V DC (max 10W consumption)

-

Weight: ~0.5 kg (1.1 lbs) (typical for Mark IV modules)

- Certifications: CE, UL (inferred from GE industrial product standards)

DS3800HAIA1E1D

Field Application & Problem Solved

Problem:

In legacy GE Mark IV turbine control systems, integrating modern field devices (e.g., high-resolution sensors, smart actuators) with existing VMEbus architectures is challenging. Non-compatible modules cause signal degradation, communication delays, and increased downtime—critical issues for power plants relying on 24/7 turbine operation. For example, a natural gas power plant upgrading its turbine sensors needed a module that could handle 16-bit analog signals without replacing the entire control system.

Solution:

The DS3800NHVM1E1D acts as a high-performance interface between VMEbus-based controllers (e.g., GE Fanuc 90-30 series) and field devices. Its 16-bit analog I/O channels ensure precise signal acquisition/transmission, while VMEbus Rev. C.1 compatibility guarantees seamless integration with existing Mark IV systems. The 32-bit processor enables real-time processing of complex control algorithms (e.g., PID loops), improving turbine efficiency and stability. Galvanic isolation (via optocouplers) protects sensitive controller circuits from voltage spikes and electromagnetic interference (EMI), ensuring reliable operation in harsh industrial environments.

Typical Use Cases:

-

Power Generation: Processes signals from gas/steam turbine sensors (e.g., pressure, temperature, flow) and controls actuators (e.g., fuel valves, inlet guide vanes) to optimize power output.

-

Manufacturing: Integrates with assembly line sensors (e.g., proximity switches, encoders) and actuators (e.g., servo motors) for precise motion control.

-

Petrochemical Industry: Manages signals from refinery equipment (e.g., distillation column sensors, pump controllers) to ensure safe and efficient process operation.

Core Value:

Enables legacy system modernization without full replacement, reducing costs and downtime. Its high-resolution I/O and real-time processing capabilities improve turbine performance and extend the lifespan of existing Mark IV infrastructure.

Installation & Maintenance Pitfalls (Expert Tips)

Based on field experience with similar Mark IV modules:

-

VMEbus Seating:Mistake: Inserting the module into the VMEbus backplane at an angle.Result: Bent pins or intermittent communication faults between the module and the turbine control unit (TCU).Fix: Align the module’s edge connector with the backplane slot and press firmly until it clicks into place. Use a torque wrench to tighten mounting screws to 0.5–1.0 Nm (7–9 in-lbs) for a secure connection.

-

I/O Configuration:Mistake: Incorrectly setting analog input ranges (e.g., configuring a 0–10V sensor to 4–20mA).Result: Signal clipping or inaccurate readings, leading to improper turbine adjustments (e.g., incorrect fuel flow).Fix: Refer to the GE Mark IV System Manual (rev. 5.0) for correct I/O configuration settings. Use a multimeter to verify sensor output ranges before connecting to the module.

-

Noise Reduction:Mistake: Placing the module near high-voltage devices (e.g., transformers, motors).Result: EMI corrupts analog signals, causing false alarms or unstable turbine operation.Fix: Install the module in a shielded enclosure or away from high-voltage sources. Use shielded twisted pair (STP) cables for field device connections and ground the shield at the module end.

-

Regular Maintenance:Mistake: Neglecting to update the module’s firmware or clean connectors.Result: Firmware bugs or poor contact lead to unexpected downtime.

Fix: Check for firmware updates quarterly (via GE’s customer portal). Inspect the module’s connectors every 6 months for corrosion or looseness; clean with a contact cleaner (e.g., DeoxIT) if necessary.

DS3800HAIA1E1D

Technical Deep Dive & Overview

The DS3800NHVM1E1D is a digital signal processing (DSP) module designed for GE Mark IV turbine control systems—a legacy platform widely used in power generation and industrial automation. It leverages the VME64 standard to provide reliable, real-time signal processing for systems requiring high durability and compatibility with existing VMEbus architectures.

How It Works:

-

Signal Acquisition: Receives analog/digital signals from field devices (e.g., pressure sensors, limit switches) via configurable I/O channels.

-

Signal Conditioning: Filters and scales signals (e.g., converting 4–20mA to 0–10V) to ensure compatibility with the VMEbus controller.

-

Real-Time Processing: The 32-bit processor executes control algorithms (e.g., PID) to adjust turbine parameters (e.g., fuel flow, blade angle).

-

Signal Output: Sends processed signals to field actuators (e.g., solenoid valves, motors) via analog/digital outputs.

-

VMEbus Communication: Transmits data to/from the VMEbus controller (e.g., GE Fanuc 90-30) for system-wide coordination.

Key Components:

-

VMEbus Interface: Conforms to VMEbus Rev. C.1 standards, ensuring seamless integration with VME64 backplanes.

-

Analog/Digital I/O: High-resolution channels (16-bit analog, 24V DC digital) for precise signal handling.

-

DSP Processor: Enables real-time processing of complex control logic.

-

Galvanic Isolation: Optocouplers protect against voltage spikes and EMI.

Failure Modes:

-

VMEbus Communication Errors: Loose connections or bent pins cause CRC errors or timeouts.

-

I/O Channel Failure: Overloading (e.g., connecting a 24V device to a 5V input) damages channels.

-

Processor Overheating: Dust accumulation or inadequate cooling leads to thermal shutdown.

Diagnostic Tips:

-

Use a VMEbus analyzer to check for communication errors (e.g., CRC mismatches).

-

Monitor the module’s status LED (if equipped): Blinking = normal; Solid = fault.

-

Use a multimeter to test I/O channel continuity (e.g., 0 ohms for digital inputs, 4–20mA for analog inputs).

Conclusion

The GE DS3800NHVM1E1D is a critical component in the Mark IV series, designed to bridge legacy VMEbus systems with modern field devices. Its high-resolution I/O, real-time processing, and VMEbus compatibility make it an essential tool for maintaining reliable turbine operation in power plants and industrial facilities. While official datasheets are scarce, insights from similar Mark IV products and supplier documentation highlight its value in legacy system modernization. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.