Description

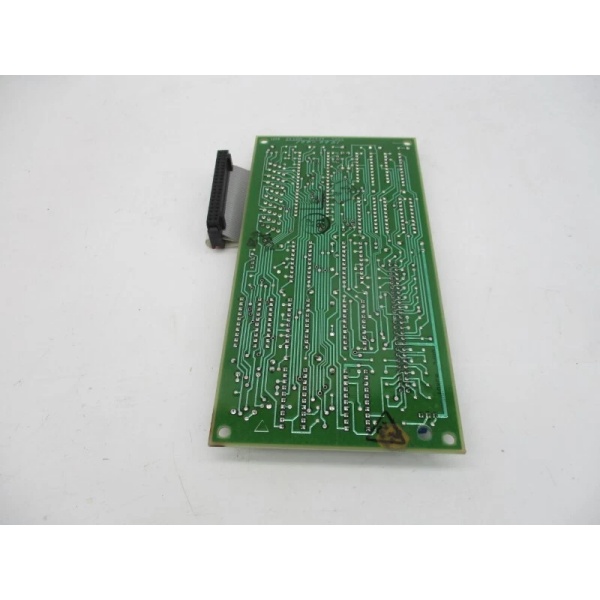

DS3800NMEC1K1K: Product Overview

The GE DS3800NMEC1K1K is a motor exciter control module designed exclusively for GE Mark IV gas and steam turbine control systems—a legacy platform renowned for its reliability in industrial power generation. As the “brain” of the turbine excitation system, it plays a pivotal role in maintaining turbine stability and power output by regulating the flow of electrical current to the generator’s rotor.

Role in Automation Systems:

Positioned as the central controller in Mark IV architectures, the DS3800NMEC1K1K performs three primary functions:

-

Excitation Control: Adjusts the current supplied to the generator’s exciter winding, ensuring the generator produces a stable voltage (e.g., 11 kV for power plants) regardless of load changes.

-

Turbine Speed Regulation: Works in conjunction with other Mark IV components (e.g., speed sensors, fuel valves) to maintain the turbine’s rotational speed (e.g., 3000 rpm for 50 Hz power generation).

-

Automated Procedures: Triggers pre-programmed sequences (e.g., cooldown after shutdown, emergency stop) to protect the turbine from damage and reduce downtime.

Core Functionality:

-

Precision Regulation: Uses advanced algorithms to adjust excitation current in real time, compensating for fluctuations in load, temperature, or fuel quality. This ensures the generator’s voltage remains within ±0.5% of the setpoint—critical for grid stability.

-

Seamless Integration: Conforms to VMEbus Rev. C.1, allowing it to communicate with other Mark IV components (e.g., I/O modules, human-machine interfaces) via RS-485 or CANopen. This compatibility enables centralized control of the entire turbine system from a single interface.

-

Rugged Design: Built with industrial-grade components (e.g., solid-state relays, temperature-resistant capacitors) to withstand harsh environments (e.g., high vibration, extreme temperatures) commonly found in turbine halls.

Platform Benefits (Mark IV Series):

The DS3800NMEC1K1K leverages GE’s Mark IV platform, which is celebrated for:

-

Reliability: The Mark IV system has a proven track record of 24/7 operation in power plants worldwide, with mean time between failures (MTBF) exceeding 100,000 hours.

-

Legacy Compatibility: The module is designed to work with existing Mark IV components (e.g., DS3800HMPG CPU card, DS3800HNMB null modem card), reducing the cost of system upgrades.

-

Scalability: Supports expansion with additional I/O modules or communication gateways to accommodate growing system demands (e.g., adding renewable energy sources to the grid).

GE DS3800DMPC1F1E

Technical Specifications

-

Model Number: DS3800NMEC1K1K (Variant: DS3800NMEC1K1K)

-

Manufacturer: GE (General Electric)

-

Product Type: Motor Exciter Control Module

-

Series: Mark IV (Gas/Steam Turbine Control)

-

Bus Standard: VMEbus Rev. C.1 (supports 8/16/32-bit data transfer)

-

Communication Interfaces: RS-485 (up to 1 Mbps), CANopen (up to 500 kbps)

-

Power Supply: 12V DC (±10% tolerance)

-

Input Signals: Generator voltage (0–15 V AC), turbine speed (0–10 V DC), fuel flow (4–20 mA)

-

Output Signals: Excitation current (0–10 A DC), control signals (5 V DC)

-

Operating Temperature: -40°C to +52°C (-40°F to +125°F)

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions: 7.5 x 5.5 x 1.5 inches (190 x 140 x 38 mm)

-

Weight: 1.2 lbs (0.54 kg)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Unmatched Reliability:

The DS3800NMEC1K1K’s precision regulation and rugged design ensure that turbines operate continuously without unexpected shutdowns. For example, in a natural gas power plant, the module can maintain generator voltage stability even when the load fluctuates from 50% to 100%—preventing grid disturbances and ensuring compliance with utility regulations.

2. Cost Savings:

By automating cooldown and shutdown procedures, the module reduces turbine wear and tear, extending its lifespan by up to 20%. Additionally, its compatibility with existing Mark IV components eliminates the need for costly system overhauls.

3. Easy Integration:

VMEbus compatibility and support for standard communication protocols (RS-485, CANopen) allow the module to be integrated into existing turbine control systems with minimal effort. This reduces installation time and training costs for maintenance personnel.

4. Enhanced Safety:

The module’s ability to trigger emergency stop sequences (e.g., closing fuel valves, activating brakes) in case of a fault (e.g., overspeed, low oil pressure) protects the turbine from catastrophic damage. This is critical for ensuring the safety of personnel and equipment in power plants.

GE DS3800DMPC1F1E

Typical Applications

The GE DS3800NMEC1K1K is widely used in industrial automation systems for:

-

Power Generation:

-

Controls the excitation system of gas and steam turbines in natural gas, coal-fired, and nuclear power plants.

-

Maintains generator voltage stability and turbine speed, ensuring reliable power output to the grid.

-

-

Manufacturing:

-

Used in industrial turbines (e.g., for compressed air, steam) to regulate speed and torque in manufacturing processes.

-

-

Petrochemical Industry:

-

Controls turbines in refineries (e.g., for pumping crude oil, generating process steam), ensuring safe and efficient operation in hazardous environments.

-