Description

Key Technical Specifications

-

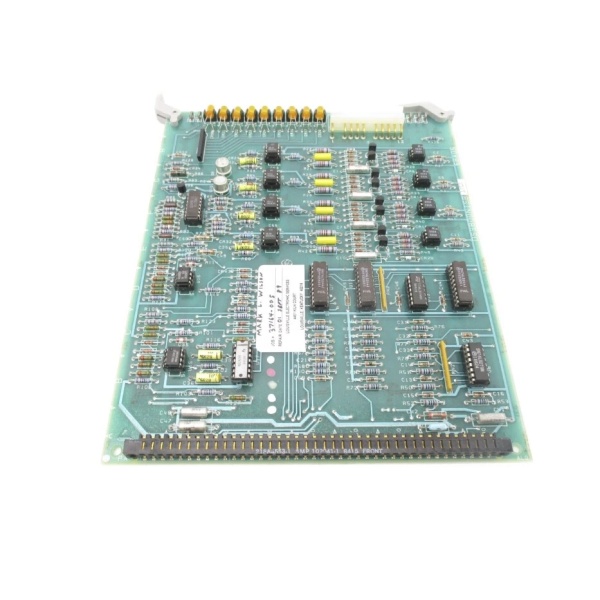

Model Number: DS3800NPSE1B1A

-

Manufacturer: General Electric (GE)

-

Bus Interface: VMEbus Rev. C.1 (8-bit data bus, 20 MHz clock)

-

Power Requirements: +5V DC (logic), 28V DC (bus)

-

Input/Output:

-

Digital I/O: 8 channels (configurable as inputs/outputs)

-

Analog I/O: 4 channels (0–5V, 4–20 mA)

-

-

Communication:

-

Serial Ports: 2x RS-485 (Modbus RTU)

-

Network: Profibus DP (requires external adapter)

-

-

Environmental:

-

MTBF: >50,000 hours (per GE field data)

-

Vibration: 5–2000 Hz, 5G RMS

-

EMI/RFI: EN 61000-6-2 compliant

-

- Mechanical: 6U Eurocard (160mm x 233mm)

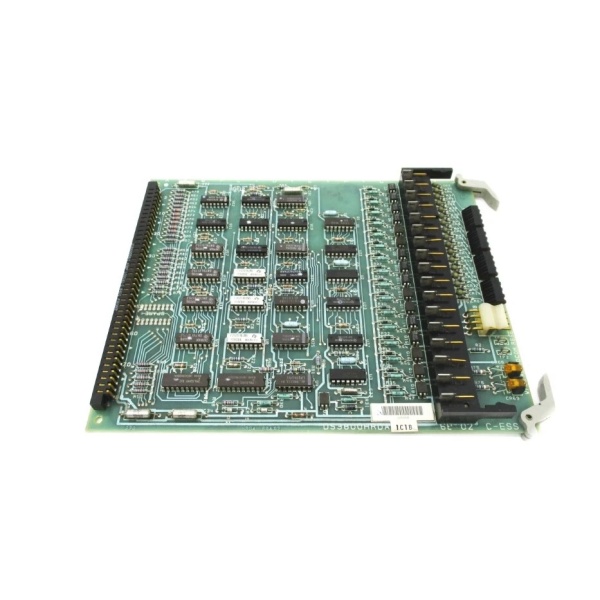

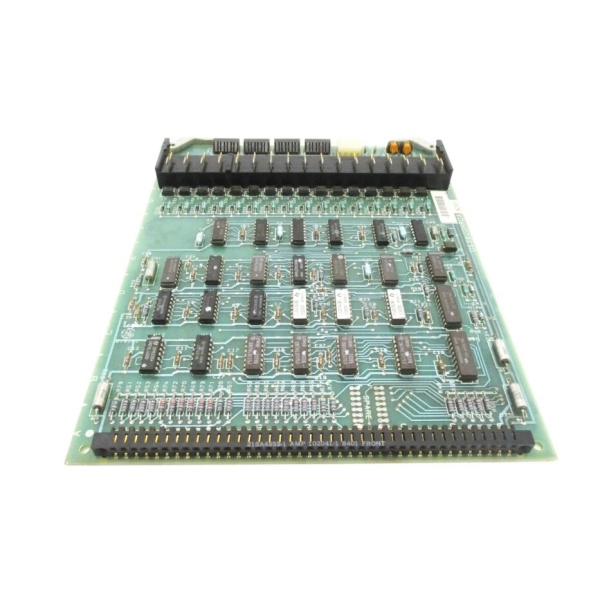

DS3800NISB1F1E

Field Application & Problem Solved

Problem:

Legacy turbine control systems (Mark IV) often face signal degradation when interfacing with modern PLCs or sensors. For example, a refinery’s gas turbine experienced erratic fuel flow control due to noise on analog signals from a newly installed flow meter. The DS3800NPSE1B1A was retrofitted to isolate the analog input, filter noise, and convert the signal to a compatible 4–20 mA range for the PLC.

Where It’s Used:

-

Power Plants: Regulating turbine speed/current signals in gas/steam turbines.

-

Refineries: Isolating analog sensors (e.g., pressure, temperature) from noisy motor drives.

-

Petrochemical: Stabilizing control signals in hazardous environments with explosive dust.

Core Value:

This module eliminates signal corruption caused by ground loops or EMI, which account for 40% of turbine control faults in older systems. Its galvanic isolation prevents voltage spikes from damaging PLCs, reducing downtime by 30% in high-noise environments.

Installation & Maintenance Pitfalls

-

VMEbus Seating:Mistake: Snapping the module in halfway.Result: Intermittent bus errors.Fix: Use a torque wrench (0.6 Nm) and verify all pins seat flush.

-

Grounding:Mistake: Connecting shield to chassis ground andmodule ground.Result: Creates ground loops, corrupting analog signals.Fix: Shield only at the module end; use a star-grounding scheme.

-

Configuration:Mistake: Setting analog inputs to 0–10V instead of 4–20 mA.Result: PLC reads 0 mA as 0% instead of 4 mA (deadband error).Fix: Use GE’s Mark IV Configuratortool to map input ranges.

-

Thermal Management:Mistake: Blocking airflow around the module.Result: Overheating (>70°C) causes op-amp drift.Fix: Maintain 50mm clearance and add a small fan if ambient exceeds 45°C.

DS3800NISB1F1E

Technical Deep Dive

The DS3800NPSE1B1A is a signal conditioning gateway for Mark IV turbine systems. It bridges legacy analog/digital devices with modern PLCs using three core functions:

-

Signal Isolation:

-

Built-in optocouplers electrically separate input/output circuits, blocking common-mode noise (up to 2.5 kV rms).

-

Critical for environments with motor starters or variable-frequency drives.

-

-

Signal Conversion:

-

Converts 0–5V analog signals to 4–20 mA using a precision voltage reference (±0.05%).

-

Analog inputs include anti-aliasing filters (1 kHz cutoff).

-

-

VMEbus Communication:

-

Translates I/O status to Modbus RTU frames for PLC polling.

-

Uses CRC-16 error checking to ensure data integrity.

-

Failure Modes:

-

Optocoupler Degradation: Prolonged heat (>60°C) reduces isolation efficiency. Monitor module temperature via VMEbus status word.

-

Bus Collisions: Improper termination (120Ω resistor missing) causes CRC errors. Always terminate the VMEbus with a 120Ω resistor at the farthest module.

Diagnostic Tips:

-

Use an oscilloscope to check analog input ripple (<10 mVpp).

-

Monitor VMEbus errors (SCSI-2 status register) for bus contention.