Description

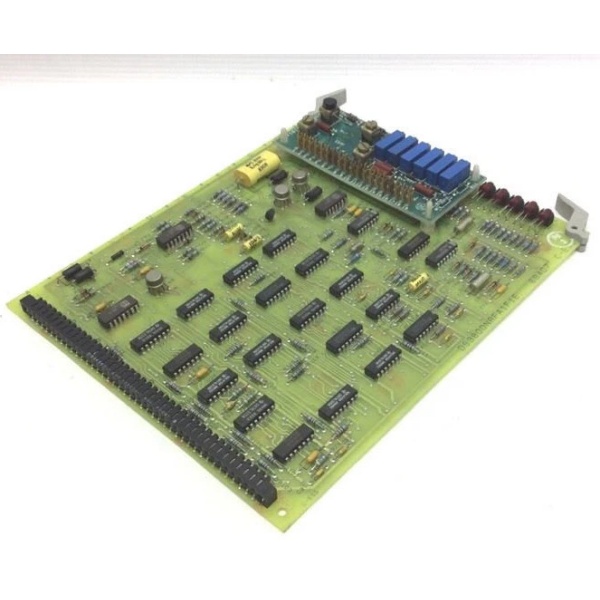

DS3800NRFA1F1E: Product Overview

The GE DS3800NRFA1F1E is a ramp and follower board belonging to the Mark IV series (a legacy platform for GE turbine control systems). It is engineered for precision control of turbine acceleration and deceleration in gas and steam turbine applications. As part of the Mark IV ecosystem, it acts as a “process controller” between the turbine control unit and field devices (e.g., fuel valves, steam inlet valves), ensuring that turbine speed and load follow predefined ramp profiles during startup, shutdown, and load changes.

Role in Automation Systems:

Positioned as a “turbine process interface” in Mark IV architectures, the DS3800NRFA1F1E performs two primary functions:

-

Ramp Rate Control: Manages the rate of change of turbine speed (e.g., 5%/minute acceleration) to prevent mechanical stress during startup or load increases.

-

Setpoint Following: Adjusts turbine control signals (e.g., fuel flow, steam pressure) to ensure the turbine follows the setpoint commanded by the control system, maintaining stable operation.

Core Functionality:

-

Precision Ramp Profiles: The board uses digital signal processing (DSP) algorithms to generate smooth ramp profiles, reducing wear and tear on turbine components (e.g., blades, bearings).

-

Setpoint Tracking: Continuously compares the turbine’s actual speed/load to the setpoint and adjusts control signals to minimize deviation, ensuring stable power output.

-

Legacy Compatibility: Designed to work with existing Mark IV components (e.g., I/O racks, terminal boards), reducing the cost of system upgrades.

-

Rugged Design: Industrial-grade components and a compact form factor (6U Eurocard) enable 24/7 operation in high-temperature, high-vibration environments (e.g., turbine halls).

Platform Benefits (Mark IV Series):

The DS3800NRFA1F1E inherits the Mark IV platform’s strengths, including:

-

Reliability: The Mark IV system is a proven platform for turbine control, with a track record of 24/7 operation in power plants worldwide.

-

Scalability: Supports expansion with additional I/O modules to accommodate growing system demands (e.g., adding more sensors to a turbine control system).

-

Easy Integration: Compatible with GE Fanuc/Emerson PLC/PAC systems, ensuring seamless integration with existing automation architectures.

DS3800NRFA1F1E

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS3800NRFA1F1E (Variant of Mark IV Series)

|

|

Manufacturer

|

GE (General Electric)

|

|

Product Type

|

Ramp and Follower Board

|

|

Series

|

Mark IV (Turbine Control Systems)

|

|

Function

|

Ramp rate control, setpoint following, signal conditioning

|

|

Bus Compatibility

|

VMEbus Rev. C.1 (fits into Mark IV I/O racks)

|

|

Operating Temperature

|

0°C to +55°C (industrial-grade)

|

|

Storage Temperature

|

-40°C to +85°C

|

|

Humidity

|

5–95% non-condensing

|

|

Form Factor

|

6U Eurocard (160 mm × 233 mm)

|

|

Weight

|

~0.5 kg (1.1 lbs)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

Core Features & Customer Value

1. Smooth Turbine Startup/Shutdown:

The DS3800NRFA1F1E’s precision ramp profiles reduce mechanical stress on turbine components, extending their lifespan. For example, in a gas power plant, the board can control the acceleration rate of the turbine during startup, preventing damage to the blades and bearings.

2. Stable Load Transitions:

The setpoint following functionality ensures that the turbine maintains stable power output during load changes (e.g., when the grid demand increases). This is critical for power plants, where unstable load can lead to grid fluctuations and penalties.

3. Legacy Compatibility:

Designed to work with existing Mark IV components, the DS3800NRFA1F1E eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark IV systems, where replacing the entire control architecture is not feasible.

4. Rugged Industrial Design:

The board’s industrial-grade construction (0°C to +55°C operating temperature, 6U Eurocard form factor) ensures reliable performance in harsh environments (e.g., turbine halls, refineries).

DS3800NRFA1F1E

Typical Applications

The GE DS3800NRFA1F1E is widely used in industrial automation systems for:

-

Power Generation:

-

Controls acceleration/deceleration profiles for gas/steam turbines in power plants, ensuring smooth startup/shutdown and stable load transitions.

-

-

Manufacturing:

-

Used in industrial turbine systems (e.g., compressor turbines) to control speed and load during production processes.

-

-

Petrochemical Industry:

-

Controls turbine-driven pumps and compressors in refineries, ensuring safe and efficient operation in hazardous environments.

-