Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | GE IC660ELB912 |

| Manufacturer | GE Fanuc |

| Product category | Network Interface Module |

| Operating Voltage | 5 V DC, 400 mA |

| Communication Protocol | Genius, Modbus RTU/ASCII, Profibus (select models) |

| Communication Rate | 5 Mbps (Genius standard); configurable from 38.4K – 153.6K via DIP switch |

| Number of Supported Devices | Up to 30 per daughterboard |

| Memory Requirement | 16 KB |

| Current Consumption | 1.0 A for single-channel PCIM; 1.5 A for dual-channel PCIM with 2 daughterboards |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions | 100 mm × 100 mm × 50 mm (DIN-rail mountable) |

| Weight | 3 lbs (1.36 kg) |

| Certifications | UL, CE, RoHS |

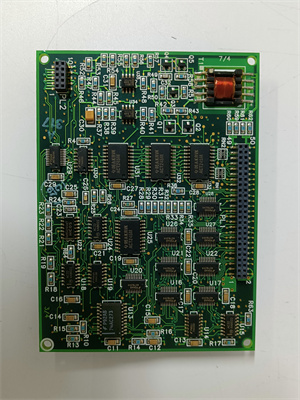

IC660ELB912

Product Introduction

The GE IC660ELB912 is a high-performance Genius network interface module designed for industrial automation systems. It serves as a daughterboard for the IBM PC Interface Module (PCIM) and enables control of remote I/O devices over the Genius I/O network. This module is part of the Genius I/O series and is designed for high-speed data communication and device management in complex industrial environments.

Core Advantages and Technical Highlights

Dual-Processor Architecture

The GE IC660ELB912 features a dual-processor setup with 6303 and 64180 microprocessors, using dual-port RAM for efficient data exchange. This architecture reduces the computational load on the host system, ensuring smooth communication within the industrial network.

High-Capacity Device Management

The module can initialize and manage faults for up to 30 devices, crucial for complex industrial setups where multiple components need to be coordinated. This enhances the overall reliability of the Genius I/O network.

Hot-Swap Capability

Support for hot-swap maintenance allows components to be replaced or upgraded without shutting down the entire system, significantly reducing downtime and increasing productivity.

Protocol Conversion

The GE IC660ELB912 can convert between Genius and other protocols like Modbus, breaking down communication barriers and enabling integration of a wide range of devices that use different protocols.

Built-in Error-Checking and Timer Functions

These features continuously monitor data transmission, preventing interruptions and ensuring the integrity of data being sent and received. This is essential for maintaining the accuracy and reliability of industrial control processes.

IC660ELB912

Typical Application Scenarios

The GE IC660ELB912 is widely used in industrial automation fields, including:

-

Manufacturing: Connecting robots, sensors, and actuators in production lines.

-

Power Generation: Monitoring essential parameters such as temperature, pressure, and flow rates in power generation plants.

-

Water Treatment: Managing the operation of multi-node pumps and valves in sewage treatment plants.

Related Model Recommendations

-

GE IC660ELB911: Similar to the IC660ELB912, it is another Genius network interface module with potentially different device management capacity.

-

GE IC660ELB913: An upgraded version of the IC660ELB912 offering enhanced performance, such as faster data processing or better compatibility with new industrial protocols.

-

GE IC693CPU364: A CPU module that works in tandem with the IC660ELB912 for overall control logic.

-

GE IC693MDL940: An I/O module that can be connected to the IC660ELB912 through the Genius network.

-

GE IC697ALG220: An analog input module often used in combination with the IC660ELB912 for collecting analog signals.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IC660ELB912, ensure that the power to the entire system is switched off to avoid electrical hazards. Check the module for any visible damage, such as bent pins or cracks on the casing. Familiarize yourself with the layout of the PLC rack where it will be installed, especially the location of the IBM PC Interface Module (PCIM) to which it will be connected. Set the DIP switches according to the desired communication rate and other configuration requirements.

Maintenance Suggestions

Regular maintenance is crucial for extending the lifespan of the GE IC660ELB912. Perform routine inspections to check for loose connections or signs of wear. Clean the module periodically to prevent dust buildup and monitor its operation to detect any potential issues early.

Service and Guarantee Commitment

The GE IC660ELB912 is backed by a comprehensive warranty, ensuring customer satisfaction and peace of mind. GE Fanuc is committed to providing exceptional after-sales service, with a dedicated technical support team available to assist with any issues or inquiries.