Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IC670ALG330-KB |

| Manufacturer | GE Industrial (VersaMax Product Line) |

| Product category | 4-Channel Industrial Analog Input Module (for VersaMax PLC Systems) |

| Input channel count | 4 differential channels (configurable per channel) |

| Supported input types | Voltage (0-10V DC, ±10V DC) / Current (4-20mA DC, 0-20mA DC) |

| Signal resolution | 16-bit (including sign bit for bipolar ranges) |

| Measurement accuracy | ±0.1% of full scale (at 25°C ±5°C); ±0.25% of full scale (0°C-60°C) |

| Isolation type | Channel-to-channel: 250V AC (rms); Module-to-backplane: 500V AC (rms) |

| Power supply | Derived from VersaMax baseplate (5V DC, 120mA max power consumption) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 31.8 mm (W) × 118.1 mm (H) × 127 mm (D) (1.25 in × 4.65 in × 5.0 in) |

| Installation method | VersaMax I/O baseplate mounting (compatible with 1-slot to 16-slot baseplates) |

| Diagnostic functions | Overrange/underrange detection, short-circuit protection, LED status indicators |

| Compatibility | All VersaMax PLC CPUs (e.g., IC670CPU310, IC670CPU320) and I/O systems |

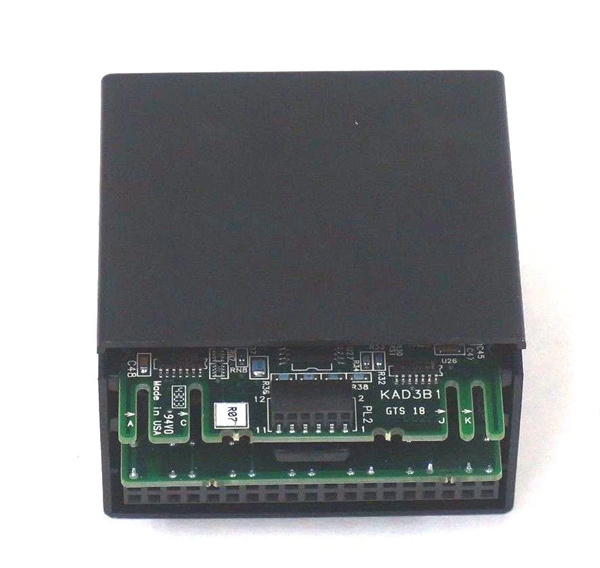

GE IC670ALG330-KB

Product Introduction

The GE IC670ALG330-KB is a flagship analog input module in GE’s VersaMax PLC product line, engineered to bridge industrial analog sensors (e.g., temperature transmitters, pressure transducers) to digital control systems. As a 4-channel differential module, the GE IC670ALG330-KB excels at converting continuous analog signals into precise digital data—critical for applications where real-time, accurate process monitoring is non-negotiable.

Unlike basic analog modules, the GE IC670ALG330-KB offers channel-by-channel configurability, allowing users to mix voltage and current inputs on the same module (e.g., 2 channels for 4-20mA pressure sensors, 2 channels for 0-10V temperature signals). This flexibility positions the GE IC670ALG330-KB as a cost-effective solution for mid-sized industrial projects, from manufacturing to utilities. In automation systems, the GE IC670ALG330-KB acts as the “sensory interface,” ensuring PLCs receive reliable data to drive decisions like process adjustments, alarm triggers, and quality control.

Core Advantages and Technical Highlights

High-precision signal acquisition: The GE IC670ALG330-KB delivers 16-bit resolution and ±0.1% full-scale accuracy at ambient temperature, outperforming entry-level 12-bit modules. This precision ensures minimal measurement error for sensitive processes—for example, in pharmaceutical manufacturing, it can reliably capture 0.1V fluctuations from pH sensors, ensuring batch consistency and regulatory compliance.

Channel-by-channel flexibility: Each of the GE IC670ALG330-KB’s 4 channels can be independently configured for voltage or current inputs via GE’s VersaPro or Proficy Machine Edition software. No physical DIP switches are required, reducing on-site configuration time and the risk of human error. For example, a food processing plant can use one channel for a 4-20mA flow sensor and another for a ±10V load cell—all on a single GE IC670ALG330-KB.

Robust isolation and protection: The GE IC670ALG330-KB features 250V AC channel-to-channel isolation, preventing cross-talk between signals and shielding the module from electrical noise (e.g., from nearby motors). It also includes short-circuit protection on all channels; if a sensor wire is accidentally grounded, the GE IC670ALG330-KB shuts down the affected channel without damaging the module or baseplate—critical for reducing maintenance costs.

Intuitive diagnostics: The GE IC670ALG330-KB integrates LED status indicators for each channel (green = normal, red = overrange/short circuit) and a module-wide “OK” LED. This allows technicians to quickly identify issues (e.g., a faulty pressure sensor) without connecting to software. For remote monitoring, diagnostic data is also transmitted to the VersaMax CPU, enabling proactive maintenance alerts via SCADA systems.

Typical Application Scenarios

In chemical processing plants, the GE IC670ALG330-KB is a cornerstone of reactor temperature control. It connects 4-20mA RTD transmitters mounted on reactor vessels to a IC670CPU320 PLC, converting analog temperature signals (e.g., 50°C-200°C) into digital data. The module’s ±0.1% accuracy ensures the PLC adjusts heating elements with sub-degree precision, preventing overheating and ensuring compliance with safety standards. Its channel isolation also protects against signal interference from nearby pumps, maintaining data integrity.

For HVAC systems in large industrial facilities, the GE IC670ALG330-KB monitors air handling units (AHUs). It uses 0-10V inputs to capture temperature (from thermistors) and humidity (from capacitive sensors) data across 4 zones. The PLC uses this data to adjust dampers and fans, optimizing energy efficiency. The GE IC670ALG330-KB’s wide operating temperature range (0°C-60°C) ensures reliable performance in mechanical rooms with fluctuating heat and humidity.

Water and wastewater treatment plants rely on the GE IC670ALG330-KB for chemical dosing control. It connects 4-20mA turbidity sensors in sedimentation tanks to the VersaMax PLC, transmitting real-time particle concentration data. If turbidity exceeds thresholds, the PLC increases coagulant dosing—all made possible by the GE IC670ALG330-KB’s fast signal conversion (100ms per channel) and short-circuit protection, which safeguards against sensor wire damage in wet environments.

GE IC670ALG330-KB

Related Model Recommendations

IC670ALG331-KB: 8-channel analog input module in the same VersaMax family as GE IC670ALG330-KB, ideal for larger systems (e.g., 8+ sensor inputs) like multi-zone HVAC.

IC670ALO320-KB: 4-channel analog output module, paired with GE IC670ALG330-KB to send control signals (e.g., 4-20mA) to actuators (valves, pumps) in closed-loop systems.

IC670CHS004: 4-slot VersaMax baseplate, required to mount GE IC670ALG330-KB and associated modules (e.g., power supplies) in compact control cabinets.

IC670PWR101: 120/240V AC to 5V DC power supply module, provides baseplate power for GE IC670ALG330-KB in non-DC-powered environments.

IC670CPU310: Entry-level VersaMax CPU, compatible with GE IC670ALG330-KB for small-to-mid-sized applications (e.g., standalone AHU control).

IC670ALG320-KB: 4-channel analog input module with fixed 0-5V/4-20mA ranges, a cost-effective alternative to GE IC670ALG330-KB for simple sensor setups.

IC200EBI001: VersaMax Ethernet communication module, works with GE IC670ALG330-KB to transmit analog data to remote SCADA systems (e.g., plant-wide energy monitoring).

IC693CMM321-JJ: GE Series 90-30 Ethernet module, compatible with GE IC670ALG330-KB via cross-platform communication for mixed PLC environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC670ALG330-KB, power off the VersaMax baseplate and verify the control cabinet meets environmental specs (0°C-60°C, 5%-95% non-condensing humidity). Required tools include a torque screwdriver (0.4-0.6 N·m for baseplate screws), wire strippers (for 22-14 AWG sensor wires), and a multimeter (to check sensor signal integrity). Align the module with the baseplate’s guide rails, push until it latches, and secure with front-panel screws—do not hot-swap the module, as this may damage the baseplate backplane. Connect sensor wires to the module’s terminal block (ensure correct polarity for current inputs: + for 4-20mA, – for ground).

Maintenance suggestions: Daily maintenance for GE IC670ALG330-KB involves checking channel LEDs—steady green indicates normal operation, while red signals overrange or short circuits. Every 6 months, use compressed air (≤40 psi) to clean dust from the module’s vents, preventing overheating. If a channel fails, first verify the sensor and wiring (use a multimeter to check for 4-20mA/0-10V signals); if the issue persists, reset the module via the baseplate’s power cycle. When replacing GE IC670ALG330-KB, ensure the new module’s firmware matches the VersaMax CPU (via Proficy Machine Edition) to avoid compatibility errors.

Service and Guarantee Commitment

The GE IC670ALG330-KB comes with a 1-year manufacturer’s warranty, covering defects in materials and workmanship under normal industrial use. GE provides 24/7 technical support via phone and online portals, with certified engineers specializing in VersaMax systems available to assist with module configuration, troubleshooting, and commissioning.

Beyond warranty, GE offers on-site service for GE IC670ALG330-KB, including module testing, calibration verification, and integration support with existing PLC systems. Global service centers stock genuine spare parts, ensuring fast replacement (typically 2-3 business days for urgent orders) to minimize downtime. GE’s commitment to quality is backed by rigorous factory testing—each GE IC670ALG330-KB undergoes 100% accuracy validation before shipment, ensuring it meets industrial performance standards from day one.