Description

Detailed Parameter Table

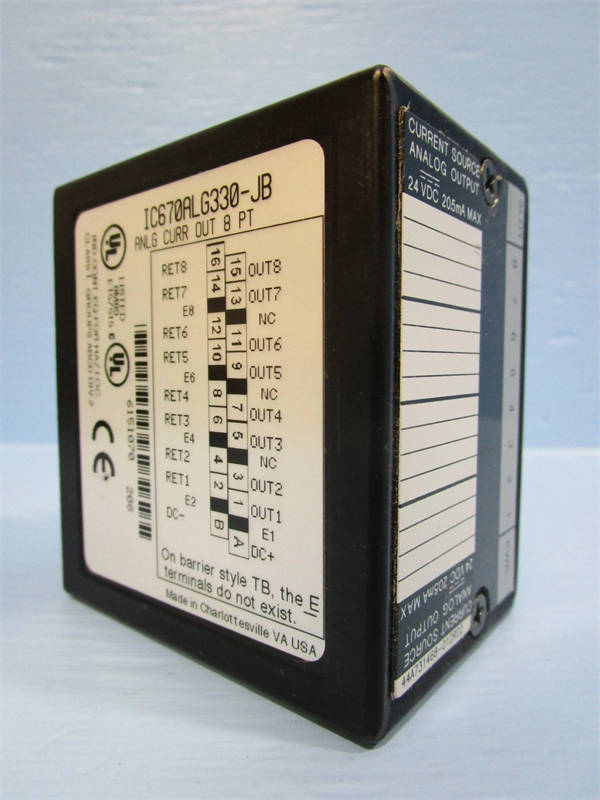

| Parameter Name | Parameter Value |

| Product model | IC670ALG330JB |

| Manufacturer | GE (General Electric) Industrial Solutions |

| Product category | VersaMax Series Analog Input Module |

| Input channel count | 8 differential analog input channels |

| Supported input signal types | Voltage (±5 V DC, ±10 V DC); Current (0-20 mA DC, 4-20 mA DC) |

| Input resolution | 16-bit (for all signal types) |

| Input accuracy | ±0.1% of full scale (at 25°C); ±0.25% of full scale (over operating temperature range) |

| Sampling rate | 100 samples per second (per channel); simultaneous sampling across all 8 channels |

| Isolation type | Channel-to-channel isolation (250 V AC rms); Channel-to-backplane isolation (500 V AC rms) |

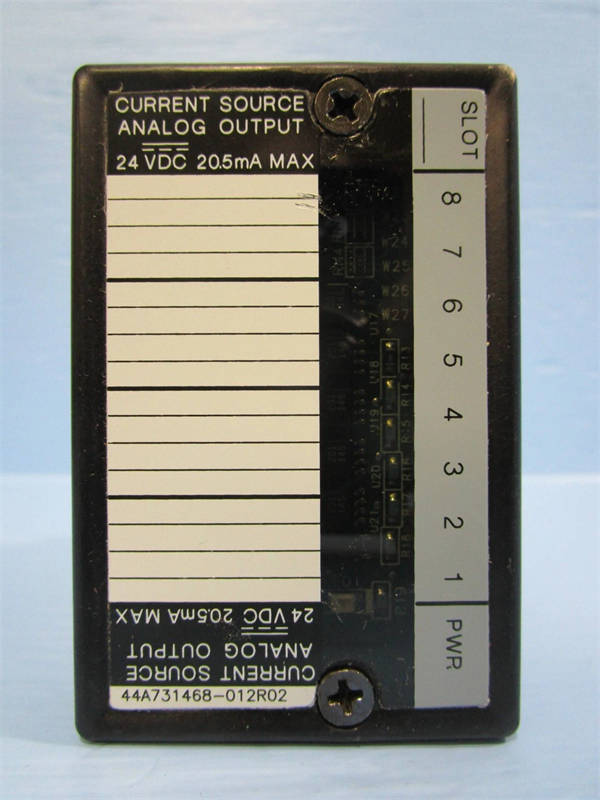

| Compatibility | GE VersaMax Micro, VersaMax Nano, and VersaMax Extreme controllers (e.g., IC670CPU310); works with VersaMax I/O racks (e.g., IC670CHS001) |

| Physical dimensions | 35 mm (W) × 100 mm (H) × 120 mm (D) (VersaMax rack-compatible) |

| Power consumption | 5 V DC, 0.3 A (powered via VersaMax I/O rack backplane) |

| Environmental operating temp | 0°C to 60°C (32°F to 140°F) |

| Environmental storage temp | -40°C to 85°C (-40°F to 185°F) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing); IP20 protection rating |

| Vibration resistance | 5 g peak (10 Hz to 2000 Hz) per IEC 60068-2-6 |

| Shock resistance | 30 g peak (11 ms duration) per IEC 60068-2-27 |

| Compliance standards | UL 508, CSA C22.2 No. 14, IEC 61131-2, CE marked, FCC Part 15 Class A |

| Diagnostic features | LED indicators (power, module status, channel overload/fault); built-in self-test (BIST); error logging via VersaMax programming software |

GE IC670ALG330JB

Product Introduction

The GE IC670ALG330JB is a high-precision analog input module designed for GE’s VersaMax series of industrial automation systems, serving as a critical component for collecting and converting analog signals from industrial sensors into digital data usable by VersaMax controllers. As an 8-channel differential module, it excels at capturing voltage (±5 V, ±10 V) and current (0-20 mA, 4-20 mA) signals—common outputs from sensors measuring temperature, pressure, flow rate, and level in industrial processes.

Unlike basic analog input modules, the GE IC670ALG330JB offers 16-bit resolution and ±0.1% full-scale accuracy, ensuring precise data collection for applications where measurement precision directly impacts product quality or process safety. It integrates seamlessly with VersaMax controllers (such as the IC670CPU310) and I/O racks (e.g., IC670CHS001) via the VersaMax backplane, eliminating the need for external wiring for controller communication. With simultaneous sampling across all 8 channels and channel-to-channel isolation, the module is ideal for medium-scale industrial applications like food and beverage processing, HVAC systems, and water treatment plants—where reliable, accurate analog data is essential for efficient control.

Core Advantages and Technical Highlights

High precision and sampling performance: The GE IC670ALG330JB delivers industry-leading accuracy, with ±0.1% of full scale at 25°C and 16-bit resolution—outperforming many entry-level analog input modules (which typically offer 12-bit resolution and ±0.5% accuracy). This precision ensures that even small changes in sensor signals (e.g., a 0.01 V shift in a temperature sensor output) are detected, making it suitable for applications like pharmaceutical manufacturing, where strict process control (e.g., reactor temperature within ±0.5°C) is required. Additionally, its 100 samples per second per channel and simultaneous sampling across all 8 channels prevent data skew between channels, a critical feature for synchronized process monitoring (e.g., measuring pressure at multiple points in a pipeline).

Robust isolation for noise immunity: The GE IC670ALG330JB features channel-to-channel isolation (250 V AC rms) and channel-to-backplane isolation (500 V AC rms)—a significant advantage over non-isolated modules. This isolation protects the module and connected VersaMax controller from electrical noise, ground loops, and voltage surges common in industrial environments (e.g., from nearby motor drives or welding equipment). For example, in an automotive factory, where electromagnetic interference (EMI) is prevalent, the module’s isolation ensures that analog signals from pressure sensors are not corrupted, maintaining accurate data for the IC670CPU310 to control robotic assembly tasks. This reduces measurement errors and minimizes unplanned downtime caused by noise-related faults.

Flexible signal compatibility and easy configuration: The GE IC670ALG330JB supports four common analog signal types (±5 V, ±10 V, 0-20 mA, 4-20 mA) across all 8 channels, eliminating the need to mix and match modules for different sensors. Each channel can be independently configured via GE’s VersaPro or Proficy Machine Edition software—no hardware jumpers required. For instance, a water treatment plant can use the same module to collect 4-20 mA signals from flow meters and ±10 V signals from level sensors, simplifying system design and reducing inventory costs. The software also allows users to set alarm thresholds for each channel (e.g., alert if a pressure sensor exceeds 15 psi), enabling proactive fault detection.

Compact design and VersaMax ecosystem integration: Measuring just 35 mm wide, the GE IC670ALG330JB saves valuable rack space in VersaMax I/O racks, allowing more modules to be installed in the same enclosure—critical for space-constrained applications like control panels in small manufacturing cells. It is fully compatible with all VersaMax controllers and racks, ensuring seamless integration into existing VersaMax systems. For example, a facility using a VersaMax Micro controller (IC670CPU301) can add the GE IC670ALG330JB to expand analog input capacity without replacing the controller or rack, reducing upgrade costs and downtime. The module’s backplane communication also ensures low-latency data transfer to the controller, maintaining real-time control performance.

Typical Application Scenarios

Food and beverage processing: In a beverage bottling plant, the GE IC670ALG330JB connects to analog sensors measuring syrup concentration (via 4-20 mA signals), bottle filling pressure (±10 V), and refrigeration system temperature (0-20 mA). Its 16-bit resolution ensures precise syrup concentration control (critical for consistent product taste), while channel isolation protects against noise from bottling line motors. The IC670CPU310 uses data from the GE IC670ALG330JB to adjust syrup pumps and filling valves in real time, reducing product waste and ensuring compliance with quality standards. The module’s ability to operate in 0°C to 60°C also makes it suitable for cold-storage areas where bottled beverages are chilled before packaging.

HVAC system control in commercial buildings: For large office complexes or shopping malls, the GE IC670ALG330JB monitors HVAC system parameters such as air temperature (4-20 mA from thermocouples), duct pressure (±5 V), and CO₂ levels (0-20 mA). Its 8 channels allow centralized monitoring of multiple zones, while simultaneous sampling ensures synchronized data for balancing airflow. The VersaMax controller uses data from the GE IC670ALG330JB to adjust heating/cooling outputs and damper positions, optimizing energy efficiency and occupant comfort. The module’s isolation prevents noise from building electrical systems (e.g., lighting, elevators) from disrupting sensor signals, ensuring reliable HVAC operation.

Water and wastewater treatment: In a municipal wastewater treatment plant, the GE IC670ALG330JB collects analog data from pH sensors (±10 V), turbidity meters (4-20 mA), and chemical dosage pumps (0-20 mA). Its high accuracy (±0.1% full scale) ensures precise pH control—critical for effective chemical treatment and compliance with environmental regulations. Channel-to-channel isolation protects the module from ground loops caused by wet conditions in treatment tanks, while the built-in fault diagnostics (LED indicators for channel overload) allow maintenance teams to quickly identify failed sensors. The IC670CPU310 uses data from the GE IC670ALG330JB to adjust chemical dosages and pump speeds, ensuring efficient treatment and minimizing chemical waste.

GE IC670ALG330JB

Related Model Recommendations

GE IC670ALG320JB: 4-channel analog input module for VersaMax, a smaller variant of the GE IC670ALG330JB. Ideal for applications requiring fewer analog inputs (e.g., small HVAC systems), offering the same precision but with reduced channel count.

GE IC670CPU310: VersaMax Micro controller, the primary control unit paired with the GE IC670ALG330JB. It processes digital data from the module to execute control logic for industrial processes.

GE IC670CHS001: VersaMax I/O rack, compatible with the GE IC670ALG330JB. Provides physical space for the module and other VersaMax I/O modules, with a backplane for power and communication.

GE IC670ALO330JB: 8-channel analog output module for VersaMax, complementary to the GE IC670ALG330JB. It converts digital signals from the controller into analog outputs (e.g., to control valves or drives), completing the analog control loop.

GE IC670DNM330JB: 8-channel digital input module for VersaMax, used with the GE IC670ALG330JB in mixed I/O systems. It collects digital signals (e.g., from limit switches) while the analog module handles sensor data.

GE IC670PWR100: Power supply module for VersaMax racks, powers the GE IC670ALG330JB via the rack backplane. Delivers stable 5 V DC and 24 V DC power, critical for the module’s precision performance.

GE IC670ALG340JB: 16-channel analog input module for VersaMax, an upgrade from the GE IC670ALG330JB for high-density applications. It offers twice the channel count for large-scale systems (e.g., multi-zone HVAC).

GE IC670BEM001: VersaMax backplane expansion module, compatible with the GE IC670ALG330JB. Extends the I/O rack backplane to remote locations, allowing the module to be installed near sensors (reducing wiring costs).

GE IC670HSC300: High-speed counter module for VersaMax, paired with the GE IC670ALG330JB in applications requiring both analog and pulse data (e.g., conveyor speed + temperature monitoring).

GE IC670CMM320: VersaMax Ethernet communication module, works with the GE IC670ALG330JB to transmit analog data to SCADA systems. It enables remote monitoring of process parameters collected by the module.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the GE IC670ALG330JB, power off the VersaMax I/O rack (e.g., IC670CHS001) and wear an anti-static wristband to prevent damage to the module’s precision components. Ensure the rack has an available slot and is powered by a compatible supply (e.g., GE IC670PWR100) to support the module’s 0.3 A power consumption. Gather tools: a screwdriver (to secure the module to the rack), torque wrench (2.5 N·m for rack screws), and shielded twisted-pair (STP) cables (for analog sensor connections—reduces noise). Verify the environment meets specs: 0°C to 60°C, 5%-95% humidity (non-condensing), and no direct exposure to liquids or excessive dust (IP20 protection).

Commissioning steps:

Align the GE IC670ALG330JB with the rack slot, ensuring the backplane connector is properly positioned, and slide the module into place. Secure it with screws using the torque wrench (2.5 N·m) to prevent loose connections.

Power on the rack and confirm the module’s LEDs: green (power), steady blue (module ready), and no red fault LEDs (indicates no channel overloads).

Connect analog sensors to the module’s input terminals: use STP cables for each channel, matching signal types (e.g., 4-20 mA sensors to current terminals, ±10 V sensors to voltage terminals). Ensure proper grounding of shielded cables to minimize noise.

Launch GE Proficy Machine Edition, connect to the VersaMax controller (e.g., IC670CPU310), and detect the GE IC670ALG330JB via the software’s “Module Scan” feature. Configure each channel: select signal type, set scaling (e.g., map 4-20 mA to 0-100 psi), and enable alarm thresholds if needed.

Test functionality: Apply a known test signal (e.g., 12 mA for a 4-20 mA channel) to each input, and verify the software displays the correct scaled value (e.g., 50 psi). Check for noise by monitoring the signal over 10 minutes—variations should be within ±0.1% of full scale.

Maintenance suggestions:

Daily: Inspect LEDs—green power, blue module ready, and no red fault LEDs indicate normal operation. A red LED signals a channel overload (e.g., a sensor short circuit) that requires immediate attention.

Weekly: Clean the module’s terminals and backplane connector with a dry, lint-free cloth to remove dust (prevents poor signal contact). Check STP cables for damage (e.g., cut insulation) and replace if necessary—damaged cables increase noise.

Monthly: Use Proficy Machine Edition to run a self-test (BIST) on the GE IC670ALG330JB—verify all channels pass and accuracy remains within ±0.25% of full scale. Calibrate the module if accuracy drifts (follow GE’s calibration procedure using a precision signal generator).

Quarterly: Check channel isolation by measuring resistance between channels with a multimeter—values should exceed 1 MΩ (indicates isolation is intact). Verify the rack power supply delivers stable 5 V DC—voltage fluctuations can degrade precision.

Annually: Replace aging sensors connected to the module (e.g., 4-20 mA pressure sensors with >5 years of use) to maintain overall system accuracy. Back up the module’s configuration (via Proficy Machine Edition) to a secure PC—critical for quick recovery if the module fails.

Service and Guarantee Commitment

The GE IC670ALG330JB is backed by a 3-year standard manufacturer’s warranty from GE Industrial Solutions, covering defects in materials, workmanship, and precision performance (e.g., accuracy drift beyond ±0.25% of full scale) under normal industrial use. During the warranty period, if the module fails to meet published technical specifications (e.g., channel isolation failure, sampling rate degradation, or LED malfunction), GE will repair or replace it free of charge, including return shipping for qualifying claims.

Beyond warranty, GE offers comprehensive support for the GE IC670ALG330JB:

24/7 technical assistance: Certified engineers specializing in VersaMax analog modules are available via phone and email to help with calibration, noise troubleshooting, and configuration issues—ensuring fast resolution of critical problems (e.g., a faulty channel causing process deviations).

Online resources: Access dedicated user manuals, calibration guides, and firmware updates on GE’s industrial support portal—tailored to the GE IC670ALG330JB’s integration with VersaMax controllers (e.g., IC670CPU310).

Extended service contracts: For mission-critical applications (e.g., pharmaceutical manufacturing), customizable contracts include annual on-site calibration, preventive maintenance checks, and expedited module replacement—minimizing downtime if the module fails.

GE’s global service network ensures rapid response: replacement GE IC670ALG330JB modules are stocked in regional warehouses, and on-site engineers can