Description

Product Overview

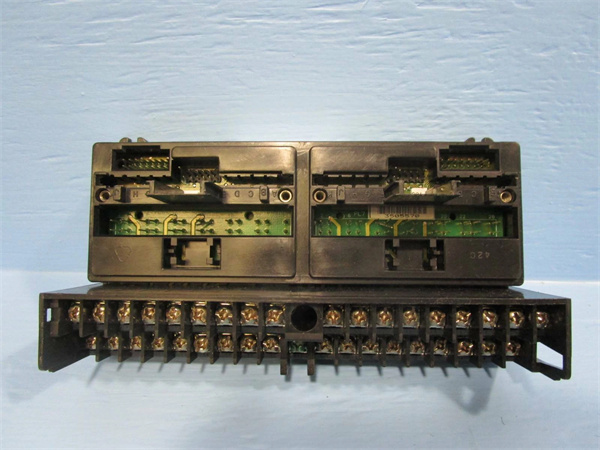

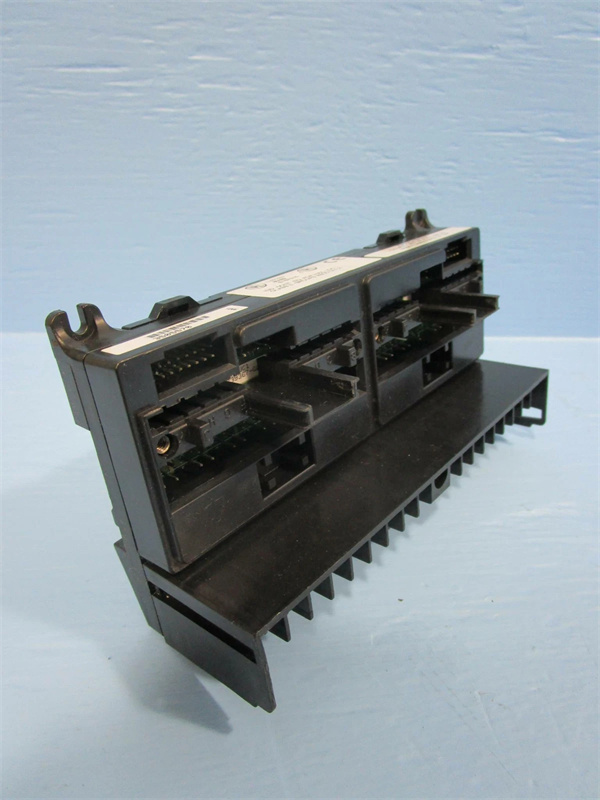

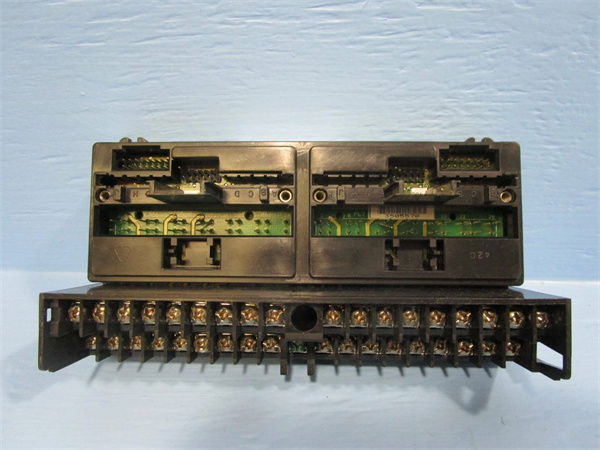

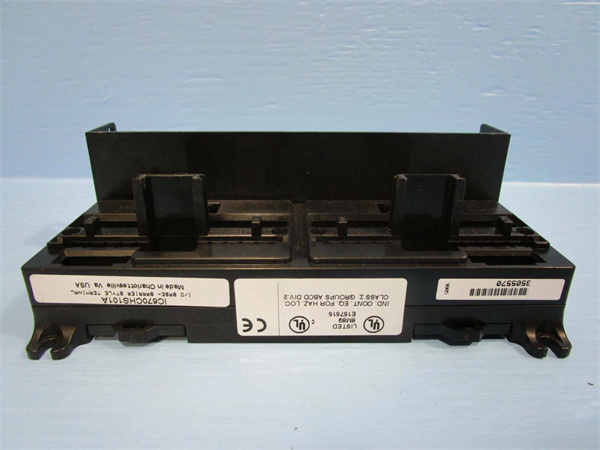

The GE IC670CHS101 is a high – performance I/O terminal block meticulously designed by General Electric for industrial automation applications. This advanced device serves as a critical interface between field devices and GE’s I/O modules, ensuring seamless data transfer and reliable power supply.

Engineered with a focus on robustness and functionality, the IC670CHS101 features a barrier – style connection design. This design allows for secure connections with cable sizes ranging from AWG #14 to AWG #22, providing flexibility in wiring configurations. It offers an impressive 37 input or output points, which play a crucial role in establishing communication links. Additionally, it supplies the necessary power to two GE Fanuc I/O modules, enabling them to function optimally. This terminal block is an integral part of GE’s field control system, contributing to the overall efficiency and stability of industrial processes. Whether in a large – scale manufacturing plant or a complex industrial facility, the GE IC670CHS101 is designed to meet the demanding requirements of modern industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

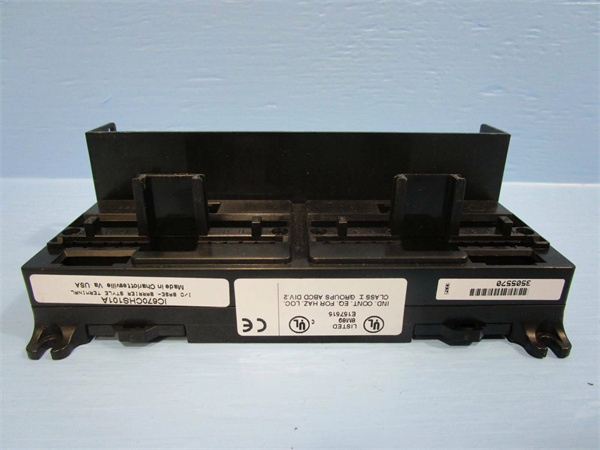

| Product Model | IC670CHS101 |

| Manufacturer | GE |

| Product Type | I/O Terminal Block |

| Number of Terminals | 37 |

| Input/Output Voltage | 24VDC |

| Maximum Current per Terminal | 10 A |

| Number of Modules per Block | 2 |

| Cable Size Compatibility | AWG #14 – AWG #22 |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Product Size | 100mm x 50mm x 20mm |

| Product Weight | 1.2 kg |

| Connection Style | Barrier – style |

| Hot Insertion Capability | Yes |

GE IC670CHS101

Main Features and Advantages

Robust Connectivity

The GE IC670CHS101 offers a reliable connection solution with its barrier – style terminals. Each connection point is physically isolated from others, providing an extra layer of protection against short – circuits or incorrect connections. This not only enhances the safety of the system but also reduces the risk of unexpected disruptions. The ability to accommodate cable sizes from AWG #14 to AWG #22 makes it adaptable to a wide range of wiring scenarios, ensuring compatibility with various field devices.

High – Current Handling

With the capacity to handle up to 10 amps of current across its terminals, this terminal block is well – suited for high – power applications. It can efficiently power the connected GE Fanuc I/O modules, enabling them to drive high – load devices without issues. This high – current handling capability is essential in industrial settings where robust power delivery is required for the proper functioning of motors, actuators, and other power – hungry equipment.

Hot Insertion Feature

Designed for hot insertion, the IC670CHS101 allows for module replacement or addition without shutting down the entire system. This is a significant advantage in applications where minimizing downtime is crucial, such as continuous manufacturing processes. Maintenance teams can quickly swap out or install new modules, reducing the time spent on system maintenance and maximizing overall productivity.

Expandability and Versatility

Featuring two modules per block, the GE IC670CHS101 offers excellent expandability. Additional modules can be easily installed, allowing for the growth of the I/O system as the needs of the industrial process change. This flexibility makes it a suitable choice for both small – scale and large – scale industrial automation projects, as it can be tailored to meet specific requirements.

GE IC670CHS101

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC670CHS101 plays a vital role in controlling and monitoring production lines. It can connect sensors, such as proximity sensors and temperature sensors, to the I/O modules, providing real – time data for process control. For example, in an automotive assembly line, the terminal block can be used to connect sensors that detect the position of parts, ensuring accurate robotic assembly. It can also power and communicate with actuators that control conveyor belts, adjusting their speed based on the production rate.

Power Generation

Power plants, whether they are thermal, hydro, or wind – powered, rely on the IC670CHS101 for various control and monitoring tasks. It can interface with sensors that measure parameters like pressure, flow, and voltage in the power generation process. The terminal block then transmits this data to the I/O modules, which are used to control the operation of generators, turbines, and other critical equipment. In a thermal power plant, it may connect sensors that monitor the temperature of the boiler, enabling precise control to optimize energy efficiency.

Oil and Gas

In the oil and gas industry, the GE IC670CHS101 is used in oil refineries, gas processing plants, and pipeline systems. It can connect to sensors that detect the composition of oil and gas, as well as pressure and flow rates in pipelines. By providing power and communication for the I/O modules, it helps in the safe and efficient operation of pumps, compressors, and valves. For instance, in a gas processing plant, the terminal block can be used to connect sensors that monitor gas quality, ensuring that only high – quality gas is processed and distributed.

Related Products

- GE IC670 series I/O modules: These modules, such as specific digital input or output modules in the series, can be connected to the IC670CHS101 terminal block. They expand the I/O capabilities, allowing for connection to a wider range of field devices. For example, a digital input module can interface with switches and sensors, while a digital output module can control relays and solenoids, all using the IC670CHS101 as the connection hub.

- GE Fanuc bus interface units: These units work in tandem with the GE IC670CHS101 as part of the field control system. The bus interface unit provides intelligent processing, I/O scanning, and feature configuration for a group of I/O modules, with the IC670CHS101 facilitating the physical connection and power supply to the I/O modules.

- GE Proficy software: This software suite, including Proficy Logic Developer PLC Machine Edition, can be used to program and manage the overall industrial control system where the IC670CHS101 is installed. It enables the creation and implementation of control logic for the I/O modules connected via the terminal block, optimizing the operation of the industrial process.

- GE IC695 series controllers: While the IC670CHS101 focuses on I/O connectivity, the IC695 series controllers can be integrated with the I/O system. These controllers process the data received from the I/O modules connected through the IC670CHS101, making decisions and sending control signals back to the field devices for coordinated operation.

- GE power supply modules: Specific power supply modules from GE are designed to work with the IC670CHS101 and the connected I/O modules. They ensure a stable and reliable power supply, which is crucial for the proper functioning of the entire I/O system, especially in high – power applications where the IC670CHS101‘s high – current handling capabilities are utilized.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670CHS101, ensure that the power to the entire system is turned off to avoid electrical hazards. Thoroughly inspect the terminal block for any visible signs of damage during transit. Check the compatibility of the terminal block with the existing system components, including the I/O modules and power supply. Follow the detailed installation guidelines provided in the product manual to correctly mount the terminal block on the appropriate rack or panel. Make sure to properly ground the terminal block by connecting it to the user – provided conductive DIN rail, which is essential for safety and proper operation.

Maintenance recommendations: Regularly check the IC670CHS101 for any signs of overheating, such as discoloration of the terminals or components. Inspect the connections of the cables to ensure they are secure and free from corrosion. Monitor the performance of the terminal block by periodically checking the communication and power supply to the connected I/O modules. If any issues are detected, refer to the product manual for troubleshooting steps. Replace any worn – out or damaged components promptly to maintain the optimal performance of the terminal block. Additionally, keep the installation area clean and free from dust and debris, as these can affect the electrical connections and overall performance of the IC670CHS101.

Maintenance recommendations: Regularly check the IC670CHS101 for any signs of overheating, such as discoloration of the terminals or components. Inspect the connections of the cables to ensure they are secure and free from corrosion. Monitor the performance of the terminal block by periodically checking the communication and power supply to the connected I/O modules. If any issues are detected, refer to the product manual for troubleshooting steps. Replace any worn – out or damaged components promptly to maintain the optimal performance of the terminal block. Additionally, keep the installation area clean and free from dust and debris, as these can affect the electrical connections and overall performance of the IC670CHS101.

Product Guarantee

GE stands firmly behind the quality of the GE IC670CHS101. The terminal block is manufactured to the highest industry standards, undergoing rigorous testing procedures to ensure its reliability and durability. In the unlikely event of a defect in materials or workmanship during the warranty period, GE offers comprehensive repair or replacement services. Their dedicated technical support team is available around the clock to assist customers with any installation – related queries, operational issues, or troubleshooting needs. This commitment to quality and customer support reflects GE’s confidence in the IC670CHS101 and its ability to meet the demanding requirements of industrial applications, providing customers with peace of mind and long – term value.