Description

Product Overview

The GE IC670MDL241J is a high – performance 16 – channel input module meticulously crafted by General Electric for industrial control systems. As part of GE’s comprehensive suite of field – control solutions, it is engineered to play a pivotal role in a wide array of automation applications. This module is designed to integrate seamlessly into industrial setups, acting as a reliable interface between field devices and the central control system.

With a rated voltage of 240V AC, the IC670MDL241J is well – equipped to handle various input signals. It is suitable for applications that demand accurate and stable data acquisition from sources such as sensors, switches, and other input – generating devices. Each of its 16 input channels operates independently, providing a high level of precision in data collection. Whether in a manufacturing plant, a power generation facility, or a water treatment plant, this module ensures that the control system receives reliable input data, enabling smooth and efficient operation of the overall industrial process.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL241J |

| Manufacturer | General Electric |

| Product Type | Input Module |

| Number of Inputs | 16 |

| Rated Voltage | 240 Volts AC |

| Input Groups | 2 |

| Input Signal Range | 0 – 20 mA |

| External Power Supply | 18 – 30 VDC |

| Nominal Supply Voltage | 24 VDC |

| Operating Temperature Range | 0 °C – 65 °C |

| Module Dimensions | [Length] x [Width] x [Height] (Please refer to the product manual for exact values) |

| Weight | [Weight in kg] (Refer to product manual for precise value) |

GE IC670MDL240J

Main Features and Advantages

Robust Design for Harsh Environments

The GE IC670MDL241J is built with durability in mind. It can withstand the harsh conditions often present in industrial settings, including temperature variations, humidity, and electrical interference. With an operating temperature range of 0 °C – 65 °C, it can function optimally in a wide variety of environments. This robust construction ensures long – term performance and minimizes the need for frequent maintenance, reducing downtime and overall operational costs.

Precise and Independent Input Channels

Each of the 16 input channels on the IC670MDL241J operates independently. This feature allows for accurate and reliable data acquisition, as each channel can be configured and monitored separately. Whether dealing with a complex network of sensors or simple on – off switches, the module can handle the input signals with precision. The ability to isolate and manage each channel also enhances the overall system’s reliability, as a problem in one channel will not affect the functionality of the others.

Versatile Input Signal Handling

This module is designed to support a wide range of input signals, with an input signal range of 0 – 20 mA. It can interface with various types of field devices, including proximity sensors, pressure sensors, and temperature sensors. This versatility makes it suitable for use in different industrial applications, from manufacturing processes that require precise control of machinery to environmental monitoring systems in power plants. The IC670MDL241J can adapt to the specific requirements of each application, ensuring seamless integration and efficient operation.

Compact and Space – Saving Design

The GE IC670MDL241J has a compact design, which allows for efficient use of space in control cabinets and other installation locations. Its small footprint makes it an ideal choice for both new installations, where space optimization is crucial, and upgrades to existing systems. Despite its compact size, it does not compromise on performance, packing all the necessary functionality into a small package. This space – saving design also simplifies the installation process, as it can be easily integrated into tight spaces without requiring extensive modifications to the existing setup.

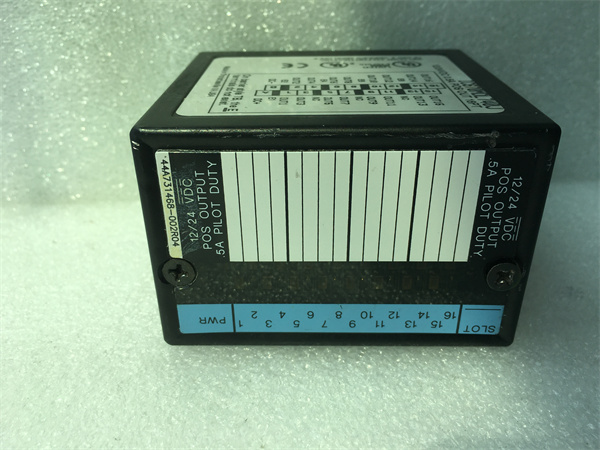

IC670MDL740

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC670MDL241J is extensively used to monitor and control production lines. It can receive input signals from sensors that detect the position of robotic arms, the status of conveyor belts, and the presence of products on the assembly line. Based on these inputs, the central control system can make real – time decisions to optimize the production process. For example, it can ensure that robotic arms pick and place components accurately, reducing errors and increasing production efficiency. In a high – speed packaging line, the module can monitor the flow of products and trigger the packaging machinery at the right time, ensuring proper packaging and minimizing waste.

Power Generation

Power generation facilities rely on the IC670MDL241J to monitor various parameters related to power generation. It can connect to sensors that measure the temperature, pressure, and vibration of turbines and generators. By providing accurate input data to the control system, the module helps in maintaining the stability and efficiency of power generation. For instance, if the temperature of a generator exceeds a certain threshold, the control system, upon receiving this input from the IC670MDL241J, can take appropriate actions such as adjusting the cooling system or reducing the load to prevent damage to the equipment. In addition, it can also be used to monitor the status of circuit breakers and other electrical components, ensuring the safe operation of the power grid.

Water Treatment Plants

In water treatment plants, the GE IC670MDL241J plays a vital role in controlling the water treatment process. It can receive input signals from sensors that measure the quality of water at different stages of treatment, such as pH levels, turbidity, and the presence of contaminants. Based on these inputs, the control system can adjust the dosage of chemicals, the speed of pumps, and the operation of filtration systems. For example, if the turbidity of the water increases, the module can send a signal to the control system, which can then increase the speed of the filtration pumps or add more flocculants to clarify the water. This helps in ensuring that the treated water meets the required quality standards before being distributed for consumption or other uses.

Related Products

- GE IC670MDL740: This is also an input module, but it may have different voltage ratings or a different number of channels compared to the IC670MDL241J. It could be used in applications where a different input configuration is required, such as those with lower voltage requirements or a need for a larger number of input channels.

- GE IC697ACC722B: A processor module from GE. While the IC670MDL241J focuses on input data collection, the IC697ACC722B is responsible for processing and coordinating operations within the control system. They often work together in an industrial control setup, with the IC670MDL241J providing the input data that the IC697ACC722B processes to make control decisions.

- GE IC693MDL940: Another input/output module. It might offer additional features like analog input/output capabilities in addition to digital, which is different from the mainly digital – input – focused IC670MDL241J. It can be used in applications that require a combination of analog and digital signal handling.

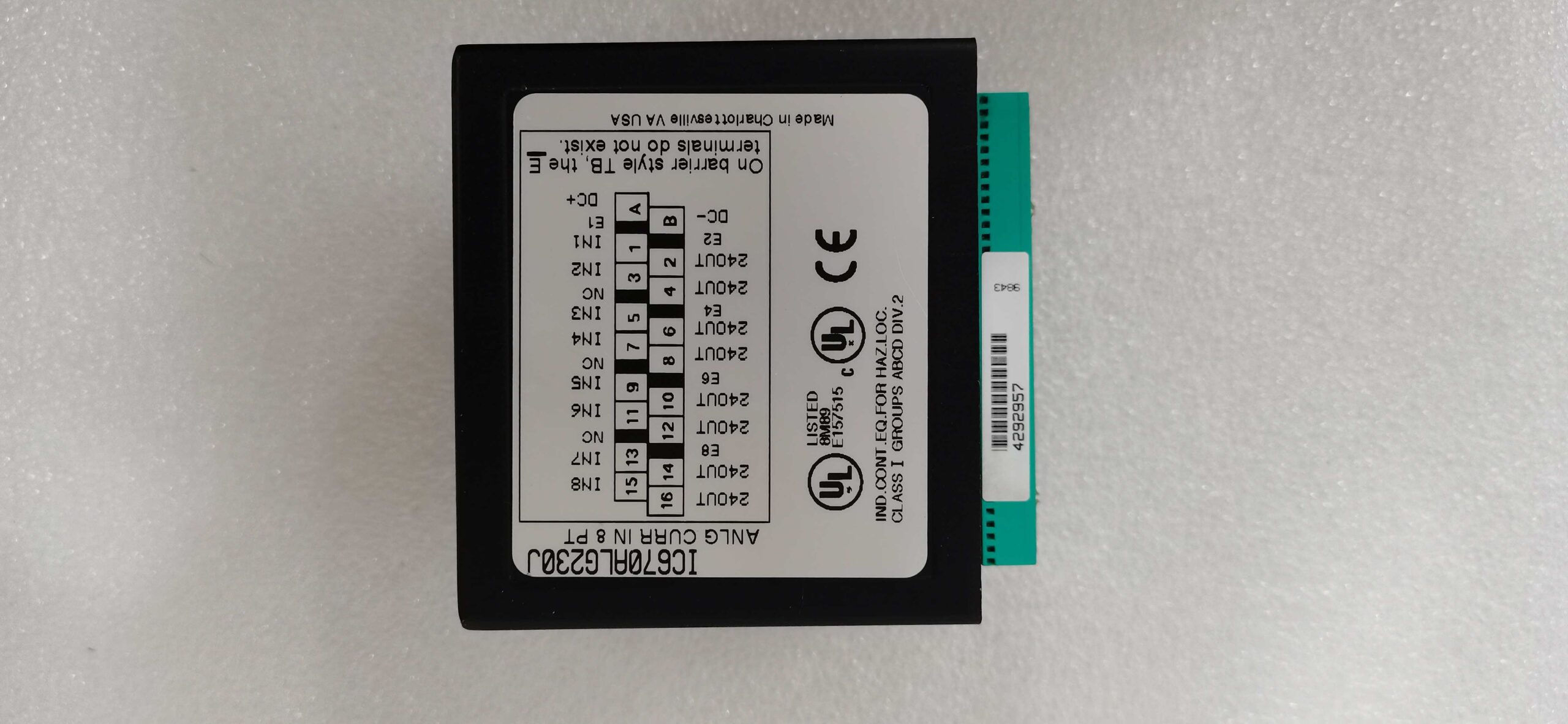

- GE IC670ALG220: An analog input module. Unlike the IC670MDL241J which deals with digital inputs, this module is designed to handle analog signals such as voltage and current. In industrial applications where both analog and digital data need to be processed, these two modules can be used in tandem to provide a comprehensive data – acquisition solution.

- GE IC670MDL240: Similar to the IC670MDL241J in terms of being a digital input module, but it may have variations in specific technical specifications, such as different input signal ranges or input group configurations. It can be an alternative choice depending on the exact requirements of the industrial control application.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670MDL241J, it is essential to ensure that the installation environment meets the specified requirements. The temperature should be within the operating range of 0 °C – 65 °C, and the area should be free from excessive humidity and electrical interference. Check the power supply to confirm that it provides a stable 24 VDC (nominal) and that the external power supply, if applicable, is within the range of 18 – 30 VDC. Verify the compatibility of the module with the existing control system, including checking for proper slot availability in the control cabinet. Also, make sure to have all the necessary tools and connectors ready for the installation process.

Maintenance recommendations: Regularly monitor the IC670MDL241J for any signs of abnormal operation. Check the status LEDs on the module to ensure that all input channels are functioning correctly. Clean the module periodically to remove dust and debris, as these can affect its performance over time. It is also advisable to perform periodic calibration checks to ensure accurate input signal readings. In case of any issues, refer to the product manual for troubleshooting steps. If the problem persists, contact GE’s technical support team, who can provide expert advice and assistance to resolve the issue and ensure the continued reliable operation of the module.

Product Guarantee

GE stands firmly behind the quality of the GE IC670MDL241J. The module undergoes rigorous quality control measures during the manufacturing process to ensure its reliability and durability. GE offers a standard warranty period, during which, if there are any defects in materials or workmanship, they will provide repair or replacement services free of charge. Their team of highly skilled technical experts is available around the clock to offer support for installation, configuration, and any technical issues that may arise during the product’s lifespan. This commitment reflects GE’s confidence in the IC670MDL241J and its dedication to providing top – notch industrial control solutions, ensuring customer satisfaction in the highly demanding industrial automation market.