Description

Product Overview

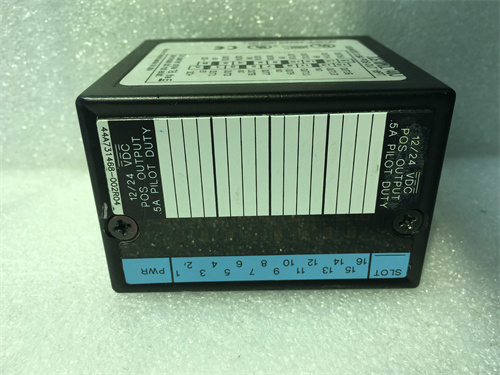

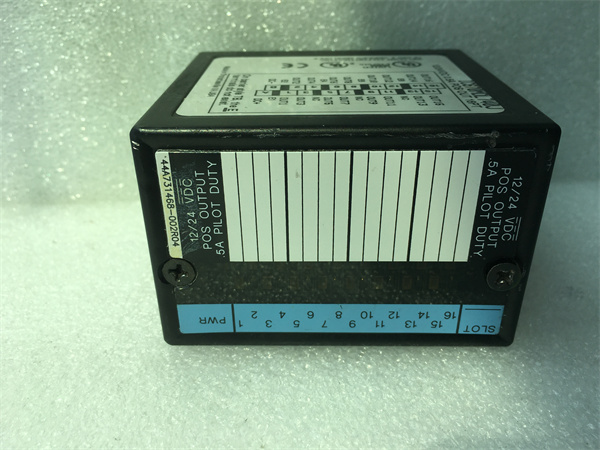

The GE IC670MDL730 is a discrete output module that plays a crucial role in industrial automation systems. As part of GE’s comprehensive lineup of control components, the IC670MDL730 is designed to provide reliable and efficient control over discrete output devices. It is widely used in various industrial applications where precise control of actuators, such as relays and solenoids, is essential.

This module offers 8 discrete output channels, each capable of handling a significant load current. With its 24VDC positive logic operation, it can effectively interface with a wide range of industrial equipment. It is engineered to work seamlessly within GE’s industrial control ecosystems, whether integrated into large – scale DCS (Distributed Control Systems) or smaller, more specialized automation setups. The IC670MDL730 is valued for its ability to enhance the overall performance and reliability of industrial processes by accurately controlling the on – off states of connected devices.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL730 |

| Manufacturer | GE |

| Product Type | Discrete Output Module |

| Output Voltage | 24VDC (Positive Logic) |

| Number of Output Channels | 8 |

| Load Current per Channel | Up to 2A |

| Short – Circuit Protection | Yes, for each channel |

| Over – Current Protection | Yes, for each channel |

| Fault Indication | LED for each output (Green for ON/OFF status, Yellow for faults) |

| Communication Interface | N/A (not a communication – focused module) |

| Operating Temperature Range | 0°C – 55°C |

| Storage Temperature Range | – 40°C – 85°C |

| Relative Humidity | 5% – 95%, non – condensing |

| Mounting | DIN – rail or panel mount |

| Weight | 0.85 kg |

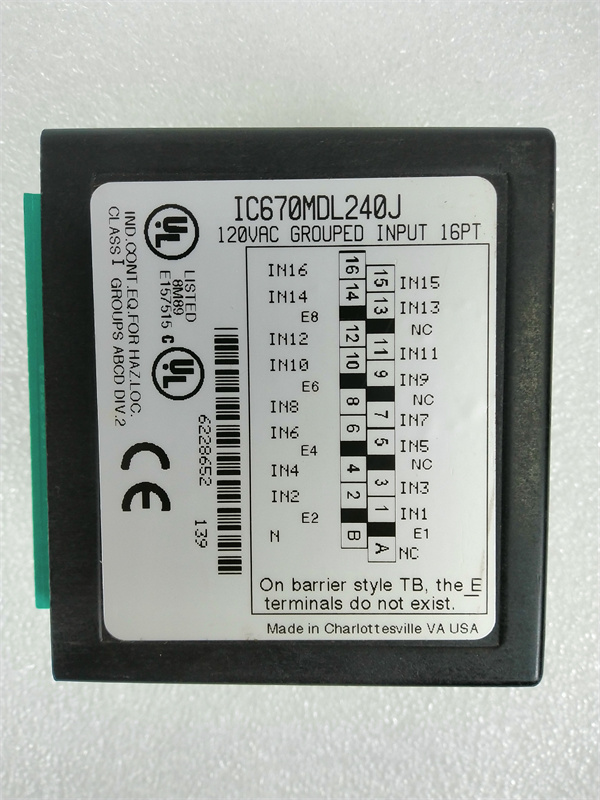

GE IC670MDL240J

Main Features and Advantages

High – Capacity Output

The IC670MDL730‘s 8 – channel design, with each channel capable of driving up to 2A of load current, makes it suitable for powering a variety of industrial actuators. This high – capacity output allows it to handle the demands of complex industrial processes, ensuring that connected devices receive sufficient power to operate reliably.

Protection Mechanisms

Each output channel is equipped with both short – circuit and over – current protection. In case of a short – circuit event, the module automatically shuts off the affected output, preventing damage to the module and connected equipment. The over – current protection also safeguards the module from excessive current draw, enhancing its long – term reliability.

Clear Fault Indication

The integrated LED indicators for each output are a major advantage. The green LED clearly shows the on – off status of the output, while the yellow LED immediately signals any faults such as short – circuits or over – currents. This visual feedback simplifies troubleshooting, allowing maintenance personnel to quickly identify and address issues, reducing downtime.

Versatile Mounting Options

With support for both DIN – rail and panel mounting, the IC670MDL730 offers flexibility in installation. This makes it adaptable to different control panel layouts and industrial environments, whether in a new installation or as a replacement in an existing system.

GE IC670MDL240J

Application Field

Manufacturing Industry

In manufacturing plants, the IC670MDL730 is used to control a wide range of equipment. For example, it can drive the solenoid valves in pneumatic systems that operate robotic arms for pick – and – place operations. By accurately controlling the on – off states of these valves, it ensures precise movement of the robotic arms, increasing production efficiency and product quality. It is also used to control relays that switch on and off motors in conveyor systems, regulating the flow of products along the production line.

Process Control

In process control applications, such as chemical plants or water treatment facilities, the module plays a vital role. It can control the actuators that operate valves in chemical reactors or water treatment tanks. For instance, it can open and close solenoid – operated valves to regulate the flow of chemicals or water, maintaining optimal process conditions. In water treatment, it can control the pumps that transfer water between different treatment stages, ensuring the smooth operation of the entire treatment process.

Energy Sector

In power generation plants, the IC670MDL730 is used to control various auxiliary equipment. It can drive the relays that control the cooling fans in generator enclosures, ensuring proper ventilation and temperature control. In wind turbines, it can be used to control the pitch of the blades by operating the solenoid valves in the hydraulic systems that adjust the blade angles, optimizing power generation based on wind speed.

Related Products

- GE IC670MDL930: Similar to the IC670MDL730, but may have different output voltage ratings or channel configurations, offering an alternative for applications with specific requirements.

- GE Fanuc I/O Rack: This provides the physical framework for mounting the IC670MDL730 and other I/O modules, facilitating proper electrical connections and system integration.

- GE Power Supply Modules: These are necessary to provide the stable 24VDC power required by the IC670MDL730. Different power supply modules may vary in terms of power capacity and additional features like voltage regulation.

- GE PLC Controllers: Work in tandem with the IC670MDL730 to send control signals to the module, enabling coordinated operation within an industrial control system.

- GE Terminal Blocks: Used to connect the wires from the controlled devices to the IC670MDL730, ensuring secure and reliable electrical connections.

Installation and Maintenance

Pre – installation preparation: Before installing the IC670MDL730, ensure that the power supply is stable and provides the correct 24VDC voltage. Check the installation area for any potential sources of electromagnetic interference. Read the installation manual carefully to understand the proper mounting method, whether it’s DIN – rail or panel mount. Prepare the necessary tools, such as screwdrivers and wire strippers. Make sure to disconnect the power from the system before starting the installation to avoid electrical hazards.

Maintenance recommendations: Regularly inspect the IC670MDL730 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the LED indicators for each output to check for any abnormal behavior or fault signals. Clean the module periodically to prevent dust accumulation, which could affect its performance. If a fault is detected, refer to the troubleshooting guide in the user manual. In case of a malfunctioning channel, check the connected devices and wiring first before considering replacing the module.

Product Guarantee

GE stands behind the quality of the IC670MDL730 with a comprehensive product guarantee. The module undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with the output channels, protection mechanisms, or general functionality, GE is committed to providing timely solutions, ensuring the IC670MDL730 operates smoothly and reliably for years to come.