Description

Product Overview

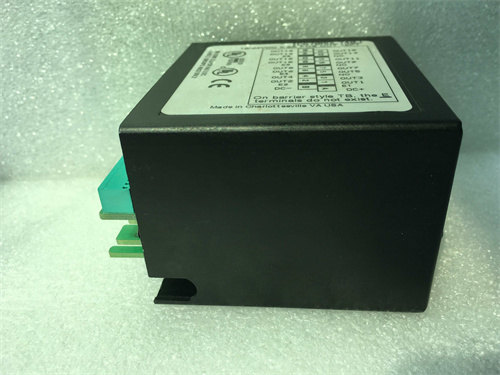

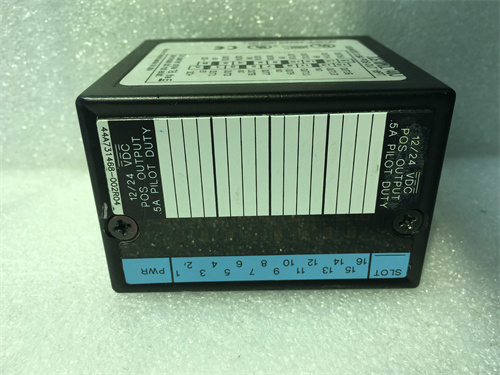

The GE IC670MDL740J is a discrete output module meticulously crafted by General Electric, designed specifically for use within the GE Fanuc series 90 – 30 and 90 – 70 Programmable Logic Controllers (PLCs). As a key component in industrial control setups, it plays a pivotal role in facilitating the connection between the PLC and external output devices. This positive logic module is engineered to offer reliable and efficient control over a wide range of equipment.

Featuring 16 output channels, the GE IC670MDL740J is a versatile solution for various industrial applications. It can supply up to 0.5 amperes of current per channel, with a total of 4 amperes per module, within a voltage output range of 10 – 30 VDC, with a nominal voltage of 24 VDC. This makes it ideal for powering devices such as 指示灯,继电器线圈,solenoid – driven equipment, and other low – current – rated output devices. By accurately controlling the power supply to these devices, it ensures the smooth operation of industrial processes, contributing to enhanced productivity and reliability in automation systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL740J |

| Manufacturer | General Electric |

| Product Type | Discrete Output Module |

| Number of Output Channels | 16 |

| Output Current per Channel | 0.5 A |

| Total Output Current per Module | 4 A |

| Output Voltage Range | 10 – 30 VDC |

| Nominal Output Voltage | 24 VDC |

| Current Drawn from Power Source | 111 mA |

| Output Response Time (0.5 A Resistive Load) | 200 ms |

| Output Voltage Drop | Max 0.5 V |

| Output Leakage Current (at 30 VDC) | 0.5 mA |

| Operating Temperature Range | [Typical industrial temperature range, e.g., -20 °C to 60 °C] |

| Input Voltage for Module | [Specify if different from output voltage, usually related to powering the module itself] |

| Mounting Type | [Describe how it mounts, e.g., on a specific type of rack or within a PLC chassis] |

IC670MDL740J

Main Features and Advantages

High – Current Output Capability

The GE IC670MDL740J‘s ability to provide 0.5 amperes per channel and 4 amperes in total per module makes it suitable for powering a variety of output devices. In industrial scenarios where multiple devices need to be driven, such as in a manufacturing assembly line with numerous solenoid valves or indicator lights, this high – current output ensures stable operation. For example, it can easily handle the power requirements of solenoid valves that control the flow of fluids in a chemical processing plant, enabling precise control over the production process.

Wide Voltage Output Range

With an output voltage range of 10 – 30 VDC, the IC670MDL740J offers flexibility in accommodating different types of external devices. This wide range means it can be used in various industrial applications where different voltage – rated devices are involved. In a food and beverage factory, for instance, it can power both low – voltage indicator lights on control panels and higher – voltage solenoid valves used in the filling and packaging machinery.

Positive Logic Design

The positive logic design of the GE IC670MDL740J simplifies the control logic within industrial systems. In a positive logic system, a high – level signal (within the specified voltage range) represents a logical “1” or an active state. This makes it easier for engineers to design and troubleshoot control systems. For example, in a power distribution system, the module can be used to control relays, and the positive logic design ensures that the correct operation of the relays is straightforward to implement and understand.

Status Indication

The module is equipped with individual status LED indicators for each output channel. These LEDs clearly show whether an output is in an on or off state. This feature is extremely useful for quick visual inspection and troubleshooting. In a large – scale industrial plant with hundreds of output devices, maintenance technicians can easily identify which channels are functioning correctly and which may have issues by simply looking at the LED indicators on the IC670MDL740J module.

Application Field

Manufacturing Industry

In manufacturing, the GE IC670MDL740J is extensively used. It can control solenoid valves in automated production lines, which are crucial for tasks like controlling the movement of parts, regulating the flow of materials, and operating pneumatic or hydraulic systems. For example, in an automotive manufacturing plant, it can be used to control the solenoid valves that operate the robotic arms’ gripping mechanisms, ensuring precise and reliable part handling. Additionally, it can drive relays that control larger electrical loads, such as motors used in conveyor systems, enabling smooth material transportation within the factory.

Process Control

In industries such as chemical processing, oil and gas, and water treatment, the IC670MDL740J plays a vital role. In a chemical plant, it can be used to control the opening and closing of solenoid – actuated valves that regulate the flow of chemical reagents, ensuring accurate mixing and reaction processes. In an oil refinery, it can power the indicator lights on control panels that display the status of various equipment, and also control relays for pumps and compressors, helping to maintain the continuous and safe operation of the refinery processes. In a water treatment plant, it can control the solenoid valves that direct the flow of water through different treatment stages, contributing to the production of clean and safe water.

Building Automation

Within building automation systems, the GE IC670MDL740J can be used to control a variety of devices. It can power the relays that control the operation of HVAC (Heating, Ventilation, and Air – Conditioning) systems, such as turning on and off fans, pumps, and dampers to maintain optimal indoor climate conditions. It can also control the lighting systems in commercial buildings, for example, by driving relays that switch lights on or off based on time schedules or occupancy sensors, helping to save energy and enhance building management efficiency.

IC670MDL740J

Related Products

- GE IC670MDL730K: This is also an output module. However, compared to the IC670MDL740J, it has 8 output points and a higher current rating of 2 A per point. It might be more suitable for applications where fewer but higher – power – consuming output devices need to be controlled.

- GE IS220PDOAH1A: A discrete output pack that can be used in combination with the IC670MDL740J to expand the overall discrete output capabilities of a system. It may offer different form factors or connection options to meet diverse installation requirements.

- GE IC694MDL632: A discrete input module. While the IC670MDL740J is for output, the IC694MDL632 is for input. In a complete industrial control system, both input and output modules work together. The input module can receive signals from sensors, switches, etc., and the IC670MDL740J can then send out control signals based on the processed input.

- GE Fanuc PACSystems RX3i Series PLCs: The IC670MDL740J is designed to be used with these PLCs. The PLCs provide the control logic and processing power, and the IC670MDL740J serves as an interface to connect the PLC to external output devices, enabling the implementation of complex automation tasks.

- GE DS200EXDEG1A: An excitation control board. Although it has a different function compared to the IC670MDL740J, in some industrial setups, both components might be part of a larger system. For example, in a power generation or motor control system, the excitation control board may work in tandem with the output module to regulate the operation of electrical equipment.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670MDL740J, ensure that the power to the PLC system is turned off to avoid electrical hazards. Check the compatibility of the module with the existing PLC model, specifically the GE Fanuc series 90 – 30 and 90 – 70. Inspect the module for any visible damage during transit. When installing, carefully follow the installation manual to correctly mount the module on the appropriate rack or within the PLC chassis. Make sure to connect the power supply wires correctly, ensuring that the voltage requirements are met. Also, verify the connection of the communication lines if applicable, as proper communication between the module and the PLC is essential for its operation.

Maintenance recommendations: Regularly check the GE IC670MDL740J for any signs of overheating, such as discolored components or abnormal heat. Clean the module periodically to remove dust and debris, as these can affect its performance and lead to overheating in a dusty industrial environment. Monitor the status LED indicators regularly to quickly identify any output channels that may have failed. If an output channel shows an incorrect state, refer to the troubleshooting section of the manual. Check the connection points of the module for any signs of looseness or corrosion. In case of a module failure, replace it with a new IC670MDL740J following the proper replacement procedure to minimize system downtime.

Maintenance recommendations: Regularly check the GE IC670MDL740J for any signs of overheating, such as discolored components or abnormal heat. Clean the module periodically to remove dust and debris, as these can affect its performance and lead to overheating in a dusty industrial environment. Monitor the status LED indicators regularly to quickly identify any output channels that may have failed. If an output channel shows an incorrect state, refer to the troubleshooting section of the manual. Check the connection points of the module for any signs of looseness or corrosion. In case of a module failure, replace it with a new IC670MDL740J following the proper replacement procedure to minimize system downtime.

Product Guarantee

GE stands firmly behind the quality of the GE IC670MDL740J. The product typically comes with a comprehensive warranty, which may cover manufacturing defects for a specified period, often one year. In the unlikely event that a customer encounters any quality – related issues during this warranty period, GE offers repair or replacement services at no additional cost. Their global network of technical support teams is readily available to assist customers. Whether it’s providing guidance during installation, helping with configuration, or troubleshooting operational problems, GE’s experts are committed to ensuring the optimal performance of the IC670MDL740J. With strict quality control measures implemented during production, GE has full confidence in the reliability of this discrete output module. This product guarantee not only reflects GE’s trust in its product but also its dedication to achieving high levels of customer satisfaction in the industrial automation market.