Description

Product Overview

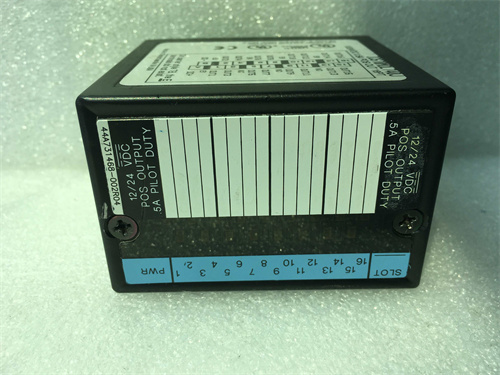

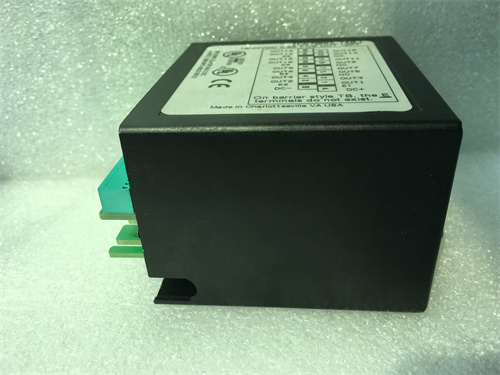

The GE IC670MDL930 is a high – performance isolated output module developed by General Electric, a renowned name in industrial automation. This module is an integral part of the company’s comprehensive range of products designed to meet the diverse needs of industrial control systems. It serves as a reliable digital output solution, playing a crucial role in ensuring seamless communication and control within complex industrial setups.

Engineered for industrial automation systems, the IC670MDL930 provides isolated digital outputs. Its isolation feature is of utmost importance as it safeguards the integrity of the signals being transmitted, preventing interference that could potentially disrupt system performance. This makes it a go – to choice for applications where high reliability and signal isolation are non – negotiable. Whether it’s in a manufacturing plant with a high – density of electrical equipment or in a power generation facility with significant electromagnetic fields, the IC670MDL930 can maintain stable and accurate output control.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL930 |

| Manufacturer | General Electric |

| Product Type | Isolated Output Module |

| Input Channels | 16 |

| Output Channels | 8 (6 normally – open (form A) contacts and 2 normally – open or normally – closed (form C) contacts) |

| Rated Voltage | 240 V AC |

| Rated Current | 1 A |

| Communication Interface | Standard industrial communication protocols |

| Operating Temperature Range | – 40 °C to 85 °C |

| Protection Rating | IP30 |

| Isolation Voltage | 1000 V AC |

| Mounting Method | DIN rail or panel mountable |

| Dimensions | 12 * 9 * 13 cm (approx.) |

| Weight | 0.3 kg (approx.) |

IC670MDL740

Main Features and Advantages

High – Quality Signal Isolation

The IC670MDL930 features a robust isolation mechanism with an isolation voltage of 1000 V AC. This ensures that signals are transmitted cleanly, free from electrical noise and interference. In industrial environments filled with numerous electrical devices, this isolation is essential for maintaining the accuracy and stability of control signals, thus reducing the risk of system malfunctions.

Multiple Output Configurations

With 8 output channels, including 6 form A (normally – open) contacts and 2 form C (normally – open or normally – closed) contacts, the module offers flexibility in controlling different types of industrial equipment. The various contact configurations allow for diverse control strategies, whether it’s powering on/off simple devices or implementing more complex control sequences.

Wide Operating Temperature Range

Capable of operating within a temperature range of – 40 °C to 85 °C, the IC670MDL930 can withstand extreme environmental conditions. This makes it suitable for use in industries where temperature fluctuations are common, such as outdoor – based mining operations, or in facilities with high – heat – generating machinery like foundries.

Standard Communication Protocols

Equipped with support for standard industrial communication protocols, the module can easily integrate with existing industrial networks. This compatibility allows for seamless data exchange between the IC670MDL930 and other components in the control system, enabling efficient monitoring and control from a central location.

Easy Installation

Designed for easy installation, the IC670MDL930 can be mounted on a DIN rail or a panel. This convenience not only saves installation time but also makes it accessible for maintenance and upgrades, contributing to overall system efficiency.

GE IC670MDL240J

Application Field

In the manufacturing industry, the GE IC670MDL930 finds extensive use in controlling various production line components. For example, it can be used to operate relays, solenoids, and contactors that control the movement of conveyor belts, the activation of robotic arms, or the operation of packaging machinery. In a food and beverage factory, it may control the filling and capping machines, ensuring precise and reliable operation.

Power generation plants also benefit from the IC670MDL930. It can be used to control the opening and closing of valves in steam or gas turbines, or to operate the motors that drive cooling fans. By providing reliable isolated outputs, it helps in maintaining the stable operation of power – generation equipment, reducing the risk of unexpected shutdowns.

In the oil and gas industry, the module is used in remote terminal units (RTUs) for controlling and monitoring equipment in harsh and hazardous environments. It can control the operation of pumps, compressors, and valves in oil pipelines or gas refineries, where the isolation of control signals is crucial for safety and system integrity.

Related Products

- IC670MDL240: This is another input/output module by GE. While the IC670MDL930 focuses on isolated digital outputs, the IC670MDL240 may have different input/output configurations, perhaps more focused on digital inputs or a combination of inputs and outputs, making it suitable for applications where a different mix of I/O functionality is required.

- IC697CPU731: A CPU module in GE’s product lineup. The IC670MDL930 can work in tandem with the IC697CPU731, where the CPU module handles the overall control logic, and the IC670MDL930 is responsible for providing the isolated digital outputs based on the commands from the CPU.

- IC660BBD025: Likely a communication – related module. It can be used to establish communication links for the IC670MDL930, enabling it to send and receive data within the industrial network more effectively, expanding the module’s reach and integration capabilities.

- IC670ALG230: An analog input/output module. In contrast to the digital – output – focused IC670MDL930, the IC670ALG230 is used for handling analog signals. In some industrial applications, both digital and analog I/O modules like these may be required to interface with a wide range of sensors and actuators.

- IC670CBL001: This could be a cable or connection – related product. It may be used to physically connect the IC670MDL930 to other components in the system, ensuring proper electrical and signal connections for the module to function as intended.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670MDL930, verify that the power supply voltage matches the module’s rated voltage of 240 V AC. Ensure the installation area is clean, free from dust, and within the specified temperature range of – 40 °C to 85 °C. Check the DIN rail or panel where it will be mounted for any damage or irregularities. Also, confirm the compatibility of the IC670MDL930 with other components in the system, such as the controller and communication devices. Make sure to have the appropriate tools for installation, like screwdrivers for securing the module to the mounting surface.

Maintenance recommendations: Regularly inspect the IC670MDL930 for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor the operating temperature of the module to ensure it remains within the specified range. Clean the module periodically to remove dust that could accumulate over time and affect its performance. Check the output signals regularly to confirm they are operating as expected. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the IC670MDL930. The module is designed and manufactured with strict quality control measures to ensure it is free from defects in materials and workmanship. In case of any quality – related issues during the warranty period, GE provides prompt repair or replacement services. Their team of experienced technicians is available around the clock to offer technical support, helping customers with installation, configuration, and any operational queries. GE’s long – established reputation for reliability in the industrial automation field gives customers confidence in the IC670MDL930‘s performance. The company’s commitment to customer satisfaction is evident in its comprehensive after – sales service, making the IC670MDL930 a reliable choice for industrial applications.