Description

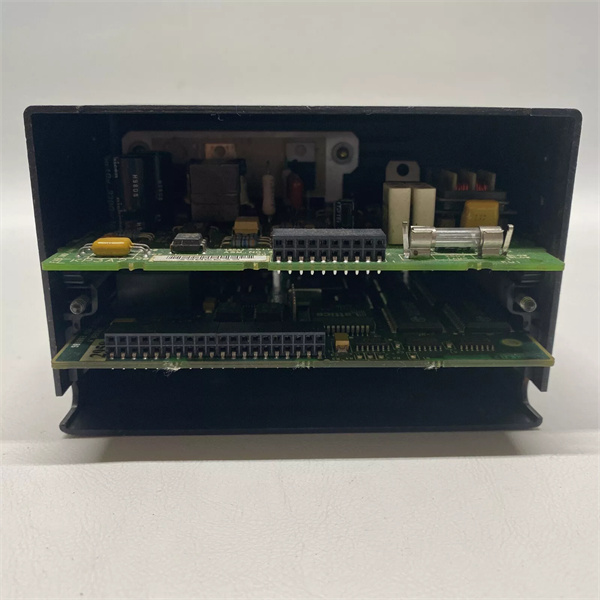

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670PBI001 |

| Manufacturer | General Electric |

| Product Type | Profibus Bus Interface Unit |

| Bus Interface | Profibus |

| Communication Speed | Up to 12 Mbps |

| Operating Voltage | 24 V DC |

| Power Consumption | Less than 0.5 W / 16.8 watts |

| Current Output to Modules | 1.4 A |

| Operating Temperature Range | – 20 °C to + 60 °C |

| Humidity Range | 0% – 95% non – condensing |

| Mounting Method | DIN rail / panel mount |

| Weight | 0.36 kg |

IC670PBI001

Main Features and Advantages

Reliable Communication

Adaptable Connectivity

Easy Installation and Maintenance

Application Field

In manufacturing industries, the GE IC670PBI001 is used to connect various production line devices such as robotic arms, conveyor belts, and sensors to the central control system. It enables real – time monitoring and control, optimizing production processes and improving product quality. For example, it can ensure that robotic arms move precisely by receiving and sending control signals based on sensor data.

In the process control sector, like in chemical plants or oil refineries, the IC670PBI001 is crucial for connecting field devices that measure and control parameters such as temperature, pressure, and flow rate. It allows for centralized control and data collection, ensuring the stability and safety of the production process. For instance, it can communicate with temperature sensors and control valves to maintain the correct reaction temperature in a chemical reactor.

In building automation, this module can be used to connect different building systems such as lighting, HVAC, and security systems. By integrating these systems, building managers can achieve energy – efficient operations and enhanced security. For example, it can adjust the lighting intensity based on the occupancy detected by sensors, reducing energy consumption.

IC670PBI001

Related Products

- IC670MDL644: A digital input module. It works in tandem with the IC670PBI001 by providing digital input signals to the overall control system, which the IC670PBI001 can then process and transmit.

- IC670GBI002: A GENIUS communication bus module. While the IC670PBI001 focuses on Profibus communication, the IC670GBI002 is for GENIUS – based communication, and they can be used in combination in complex industrial setups to support multiple communication protocols.

- IC670MDL740: A digital output module. It receives control signals processed by the IC670PBI001 and uses them to drive external devices, such as motors or solenoids, in an industrial control system.

- IC693DNS201: A communication module. It may offer different communication capabilities compared to the IC670PBI001, and can be used in parallel to expand the communication options within an automation system, for example, for communicating with devices that do not support the Profibus protocol.

- IC670ALG330: An analog input module. It provides analog input data to the system, which the IC670PBI001 can handle and integrate into the overall control and monitoring process, especially useful in applications where analog signals from sensors need to be processed.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the IC670PBI001 for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor the operating temperature and humidity to ensure they remain within the specified ranges. Periodically clean the module to remove accumulated dust, which can affect heat dissipation. Check the communication status of the Profibus network connected to the module. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance. It is also advisable to keep the module’s firmware up – to – date to benefit from the latest improvements and bug fixes.