Description

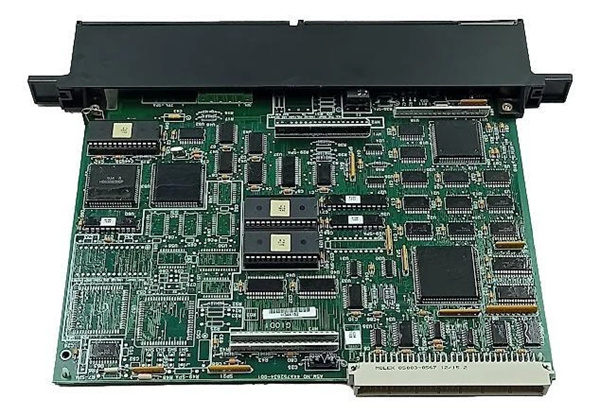

Professional Product Description: GE IC687BEM731CA Bus Expansion Module (90-30 PLC Series)

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC687BEM731CA |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Bus Expansion Module (GE 90-30 PLC Series, Genius Bus Compatibility) |

| Bus Protocol Support | Genius Bus (GE proprietary); Supports peer-to-peer communication, master/slave mode |

| Communication Speed | 1 Mbps (fixed); Maximum bus length: 1000m (with repeaters) |

| Number of Nodes Supported | Up to 32 nodes per bus segment; Expandable to 128 nodes with repeaters |

| Interface Type | Genius Bus port (5-pin terminal block); 90-30 backplane interface (parallel bus) |

| Power Requirements | 5V DC (from 90-30 backplane); Current draw: 0.2A typical, 0.3A peak |

| Physical Dimensions (H×W×D) | 110mm × 85mm × 30mm (rack-mount, 90-30 series form factor); Weight: 170g |

| Operating Temperature Range | 0°C to +60°C (ambient); -20°C to +70°C (short-term storage, <72h) |

| Environmental Protection | IP20 terminal protection; Conformal coating (moisture/dust resistance, IEC 60068-2-68) |

| Protection Features | Bus short-circuit protection; Overvoltage protection (up to 7V DC on backplane) |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1 |

| Compatibility | GE 90-30 PLC Systems (e.g., GE IC693CPU363LT, IC693CPU364); 90-30 I/O modules (GE IC693PTM100CA, IC693MDL240); Genius Bus devices (sensors, drives, remote I/O) |

GE IC687BEM731CA

Product introduction

GE IC687BEM731CA is a dedicated bus expansion module engineered for GE’s 90-30 PLC series, designed to extend the 90-30 system’s connectivity via GE’s proprietary Genius Bus—enabling seamless communication between the PLC CPU (e.g., GE IC693CPU363LT) and distributed field devices. Unlike basic communication modules limited to point-to-point links, GE IC687BEM731CA creates a scalable bus network, allowing the 90-30 system to integrate remote I/O, smart sensors, and variable-speed drives across large industrial facilities.

In industrial automation, GE IC687BEM731CA acts as the “network bridge” between the 90-30 backplane and the Genius Bus. For example, in a large automotive assembly plant, GE IC687BEM731CA connects a central GE IC693CPU363LT to 12 remote I/O racks (each with IC693MDL240 digital outputs) and 8 variable-speed drives—all via a single Genius Bus segment. The module enables real-time data exchange (e.g., conveyor speed commands, sensor status) across 500m of the plant floor, eliminating the need for costly hardwired connections between the central PLC and distributed devices.

What defines GE IC687BEM731CA is its balance of scalability and reliability: it supports up to 32 nodes per bus segment (expandable to 128 with repeaters) and includes bus short-circuit protection to prevent network-wide failures. This makes it indispensable for legacy 90-30 systems in large-scale facilities like manufacturing plants, warehouses, and water treatment plants—where distributed control and long-distance communication are critical.

Core advantages and technical highlights

Genius Bus Scalability for Large-Scale Systems: GE IC687BEM731CA eliminates the 90-30 system’s backplane slot limitations by extending connectivity to remote devices via Genius Bus. A beverage bottling plant with 4 production lines replaced 6 additional PLCs (used for distributed control) with a single GE IC693CPU363LT and 4 GE IC687BEM731CA modules. Each module managed 8 remote I/O nodes (tracking bottle fill levels, conveyor status), reducing hardware costs by 40% and simplifying system management—all I/O data is now centralized in one PLC.

1 Mbps Real-Time Communication for Time-Critical Tasks: With a fixed 1 Mbps bus speed, GE IC687BEM731CA ensures low-latency data transfer (≤10ms per node), critical for time-sensitive processes. In a metal stamping plant, the module transmits stamping press position data (from remote encoders) to the central GE IC693CPU363LT in 8ms—enabling the PLC to adjust press speed in real time and avoid material jams. This responsiveness reduced scrap rates by 15% compared to slower RS-485 networks previously used.

Bus Short-Circuit Protection for Network Resilience: Unlike unprotected bus modules, GE IC687BEM731CA includes built-in short-circuit protection—isolating faulty nodes to prevent the entire Genius Bus from shutting down. In a wastewater treatment plant, a damaged sensor cable caused a bus short; GE IC687BEM731CA detected the fault, disconnected the faulty node, and kept the remaining 18 nodes operational. This prevented a 2-hour shutdown of the plant’s pump control system, saving $8,000 in lost treatment capacity.

Seamless Integration with 90-30 Ecosystem: GE IC687BEM731CA requires no specialized software configuration—it is automatically detected by the 90-30 CPU (e.g., GE IC693CPU363LT) via the backplane, and uses the same Logicmaster 90-30 software for bus node setup. A food processing plant upgrading to distributed control simply installed GE IC687BEM731CA in the existing 90-30 rack, added 10 remote temperature sensors (via Genius Bus), and configured nodes in 30 minutes—no CPU reprogramming or backplane modifications needed.

Typical application scenarios

GE IC687BEM731CA is widely used in large-scale manufacturing, such as a 100,000-square-foot electronics assembly facility. The facility’s central GE IC693CPU363LT (mounted in the control room) connects to 3 GE IC687BEM731CA modules: one manages 12 remote I/O racks (monitoring component feeders), another integrates 8 robotic arm controllers, and the third links 6 test stations. The Genius Bus runs 800m across the facility, enabling real-time coordination between all devices—for example, if a component feeder is empty (detected by a remote sensor), the PLC pauses the corresponding robotic arm via GE IC687BEM731CA to avoid assembly errors.

During a peak production shift, a faulty robotic arm controller caused a bus current spike—GE IC687BEM731CA isolated the controller, keeping the other 24 nodes operational. Production continued at 80% capacity while the controller was repaired, avoiding a full line shutdown that would have cost $20,000.

Another key application is municipal water treatment plants, where GE IC687BEM731CA connects a central 90-30 PLC to remote pump stations and chemical dosing units. A plant with 5 pump stations (spread across 2 miles) uses 2 GE IC687BEM731CA modules to monitor flow rates (via GE IC693PTM100CA RTD modules) and control dosing valves. The Genius Bus ensures reliable communication even in wet, corrosive environments, with the module’s conformal coating preventing damage from chemical vapors.

GE IC687BEM731CA

Related model recommendations

GE IC687BEM730: Basic variant of GE IC687BEM731CA (supports 16 nodes, no short-circuit protection); ideal for small-scale distributed systems where cost is a priority.

GE IC693CPU363LT: Extended-temperature 90-30 CPU paired with GE IC687BEM731CA; enables bus expansion in harsh environments (e.g., outdoor pump stations, high-heat factories).

GE IC693RCM301: Genius Bus repeater for GE IC687BEM731CA; extends bus length to 1000m and increases node count to 128—critical for large facilities (e.g., automotive plants).

GE IC693MDL240: Digital output module integrated via GE IC687BEM731CA; controls remote devices (e.g., conveyor motors, valves) in distributed I/O racks.

GE IC693PTM100CA: RTD temperature module connected via GE IC687BEM731CA; monitors remote process temperatures (e.g., water treatment chemical tanks) and sends data to the central PLC.

GE Logicmaster 90-30 v5.5: Programming software for GE IC687BEM731CA; configures bus nodes, monitors network status, and troubleshoots communication errors.

GE IC693PWR321: 90-30 power supply module that powers GE IC687BEM731CA; provides stable 5V DC for the module and backplane, ensuring reliable bus communication.

GE Genius Bus Cable (IC687CBL700): Shielded twisted-pair cable for GE IC687BEM731CA; minimizes EMI interference in industrial environments, ensuring 1 Mbps communication speed.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IC687BEM731CA, confirm compatibility with the 90-30 CPU (e.g., GE IC693CPU363LT) and backplane revision (rev. 2.0+). Ensure the environment meets 0°C to +60°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.4–0.6 N·m), wire strippers (22–18 AWG), ESD-safe gloves, multimeter, and Logicmaster 90-30 software (v5.5+). Safety precautions: Power off the 90-30 system and apply lockout/tagout. Align GE IC687BEM731CA with an empty 90-30 backplane slot, engage the connector, and secure with M3 screws (torque to 0.5 N·m).

Wiring and commissioning: Connect the Genius Bus cable to the module’s 5-pin terminal block (follow polarity labels: V+, V-, Data+, Data-, GND). Power on the system; use Logicmaster 90-30 to detect the module and configure bus settings (e.g., node addresses for remote devices). Add Genius Bus nodes (e.g., remote I/O racks, sensors) via the software, assigning unique addresses (1–32 per segment). Test communication by sending a command to a remote output module (e.g., activate a valve via IC693MDL240) and verifying feedback from the corresponding input sensor. Confirm short-circuit protection by intentionally shorting a bus wire—module should isolate the fault and trigger an HMI alarm.

Maintenance suggestions: For daily operation, monitor GE IC687BEM731CA’s status LEDs (green = normal, red = bus fault, amber = low power) via the HMI. Every 6 months, inspect the bus cable for damage (e.g., cuts, fraying) and retighten terminal block connections (torque to 0.4 N·m). Clean the module with a dry lint-free cloth to remove dust. Annually, test bus communication speed using Logicmaster 90-30’s diagnostic tool—ensure speed remains at 1 Mbps (no degradation from EMI). If a bus fault persists after cable checks, replace GE IC687BEM731CA with a GE-approved spare—third-party modules may not support Genius Bus protocol or short-circuit protection.

Service and guarantee commitment

GE IC687BEM731CA is backed by a 24-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and Genius Bus communication performance (per UL 508C standards). For customers with large-scale distributed systems (e.g., automotive plants, water treatment facilities), GE offers a “network support program”: technical specialists provide remote bus troubleshooting within 4 hours of a reported fault, minimizing network downtime.

GE provides free access to GE IC687BEM731CA’s technical manual (including Genius Bus wiring diagrams and node configuration guides) for 18 months post-purchase. Customers also receive complimentary updates to Logicmaster 90-30’s bus diagnostic tools. For critical applications, GE offers optional on-site bus commissioning—verifying network speed, node connectivity, and fault protection to ensure compliance with industrial communication standards (e.g., IEC 61158).