Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

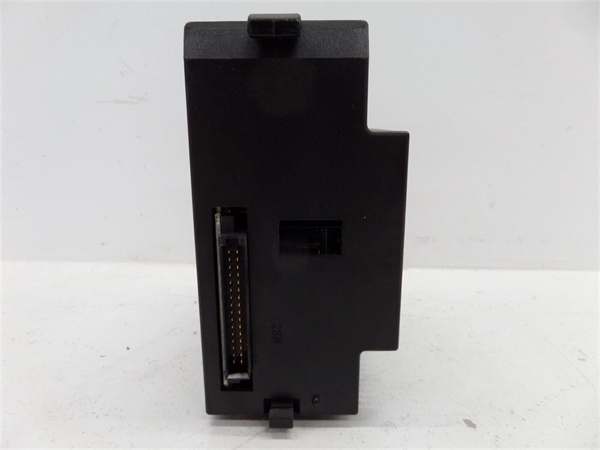

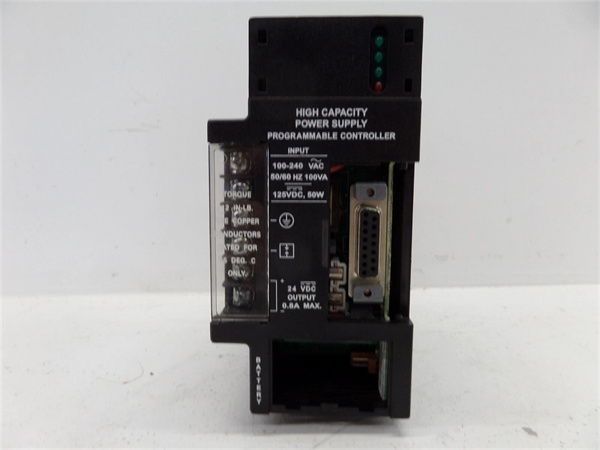

| Product model | GE IC693PWR330G |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Industrial Power Supply Module (90-30 Series PLC) |

| Input Voltage Range | 85–264V AC (47–63 Hz); 100–300V DC (wide-range compatibility) |

| Nominal Input Voltage | 120/240V AC; 125/250V DC |

| Output Specifications | +5V DC (20A, main output for 90-30 CPU/I/O); +12V DC (2A, auxiliary for analog modules); -12V DC (1A, auxiliary for serial modules) |

| Total Continuous Power | 120W (0–60°C, no forced airflow); 150W (peak, <10s for startup currents) |

| Power Factor Correction | 0.95 (90–264V AC input, full load) |

| Operating Temperature Range | 0°C to +60°C (ambient); -20°C to +70°C (short-term storage, <72h) |

| Physical Dimensions (H×W×D) | 120mm × 100mm × 35mm (rack-mount, 90-30 Chassis Slot 0); Weight: 380g |

| Protection Features | Electronic short-circuit protection (per output); Overcurrent/overvoltage protection (110% nominal); Thermal shutdown (auto-recovery at <70°C); AC line dropout tolerance (10ms) |

| Status Indicators | Green LEDs (+5V, +12V, -12V output active; AC/DC input present); Red LED (fault: overcurrent/overtemperature/input under-voltage) |

| Environmental Protection | Conformal Coating (IEC 60068-2-68, 1000h salt spray); EMI/RFI Shielding (EN 55022 Class A); IP20 Terminal Protection |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (Non-Incendive) |

| Compatibility | GE 90-30 PLC Chassis (GE IC693CHS390, GE IC693CHS320); 90-30 CPUs (GE IC693CPU374, GE IC693CPU364); 90-30 I/O Modules (GE IC693ALG221, GE IC693TCM302); 90-30 Serial Modules (GE IC693PCM311LT) |

| Input Connection | Removable 3-terminal block (accepts 14–10 AWG solid/stranded wire for AC/DC input) |

| Output Connection | Backplane-integrated (no external wiring; powers 90-30 modules via chassis bus) |

| MTBF (Mean Time Between Failures) | 400,000 hours (per MIL-HDBK-217F, 40°C ambient) |

| Humidity Tolerance | 5%–95% RH (non-condensing, per IEC 60068-2-3) |

GE IC693PWR330G

Product Introduction

GE IC693PWR330G is a robust industrial power supply module engineered exclusively for GE’s 90-30 Series PLC systems, serving as the “stable power backbone” that delivers consistent, multi-voltage power to 90-30 CPUs, I/O modules, and auxiliary devices. Unlike generic power supplies that lack 90-30 backplane integration and industrial ruggedness, GE IC693PWR330G features a wide input range (85–264V AC/100–300V DC), 120W continuous power output, and comprehensive protection mechanisms—ensuring uninterrupted operation in mid-scale automation environments (e.g., packaging lines, material handling systems, or small manufacturing cells).

As a foundational component of the 90-30 ecosystem, GE IC693PWR330G plays a critical role in maintaining system reliability: its +5V DC main output powers 90-30 CPUs (e.g., GE IC693CPU374) and digital I/O modules (e.g., GE IC693DI201), while ±12V DC auxiliary outputs support analog modules (e.g., GE IC693ALG221) and serial communication modules (e.g., GE IC693TCM302). For example, in a packaging plant, GE IC693PWR330G powers a 90-30 system controlling 8 conveyor belts and 16 product detection sensors—its wide input range handles voltage fluctuations from the plant’s grid, while thermal shutdown protection prevents damage during summer heatwaves.

Core Advantages and Technical Highlights

Wide Input Range for Global and Versatile Use: GE IC693PWR330G accepts 85–264V AC or 100–300V DC input, eliminating the need for voltage selectors or regional variants. A multinational electronics manufacturer uses GE IC693PWR330G in 90-30 systems across facilities in the U.S. (120V AC), India (230V AC), and China (220V AC)—avoiding stocking three different power supplies and reducing inventory costs by 60%. The module also works with DC power sources (e.g., backup batteries in remote sites), adding flexibility for off-grid applications.

120W Continuous Power for Dense 90-30 Configurations: With 120W continuous power, GE IC693PWR330G supports compact but dense 90-30 setups—e.g., a GE IC693CPU364 CPU, 4× GE IC693DI201 digital input modules, 2× GE IC693DO106 digital output modules, and 1× GE IC693ALG221 analog module. A food processing plant using this configuration reported no power-related issues over 3 years, while lower-wattage supplies (80W) required frequent upgrades to handle additional I/O, costing $1,500 per system.

Comprehensive Protection for System Safety: GE IC693PWR330G includes electronic short-circuit protection (per output), overvoltage protection, and thermal shutdown—safeguarding 90-30 modules from catastrophic failures. During a wiring error at a warehouse, a shorted GE IC693DO106 module triggered the power supply’s short-circuit protection; the module latched into a safe state, preventing damage to the CPU and other I/O modules. Technicians resolved the issue in 20 minutes, minimizing downtime compared to unprotected supplies (which often require full system replacement after shorts).

Backplane-Integrated Output for Simplified Installation: Unlike external power supplies that require separate wiring to each module, GE IC693PWR330G delivers power directly to 90-30 modules via the chassis backplane. A machine builder installing 20 90-30 systems reduced wiring time by 70% (from 1 hour to 18 minutes per system) compared to using external supplies—accelerating time-to-market and reducing labor costs by $4,000. The backplane integration also eliminates wiring errors (e.g., reversed polarity), a common issue with external power setups.

Typical Application Scenarios

GE IC693PWR330G excels in powering mid-scale 90-30 automation systems across industries, with three high-impact use cases:

In material handling (warehouse conveyor systems), GE IC693PWR330G powers a 90-30 system with a GE IC693CPU374 CPU, 6× GE IC693DI201 modules (monitoring photoelectric sensors for package detection), and 4× GE IC693DO106 modules (controlling conveyor motors and stop gates). Its wide input range handles voltage fluctuations from the warehouse’s backup generator, while thermal shutdown protection prevents overheating during peak operation (12-hour shifts). The module’s 400,000-hour MTBF ensures 5+ years of maintenance-free operation, critical for 24/7 warehouse operations.

In small-scale manufacturing (electronics assembly), GE IC693PWR330G supplies power to a 90-30 system controlling a pick-and-place machine: a GE IC693CPU364 CPU, 2× GE IC693ALG221 analog modules (monitoring servo motor position), and 1× GE IC693TCM302 serial module (communicating with a barcode scanner). Its ±12V DC auxiliary outputs power the analog and serial modules, while power factor correction (0.95) reduces energy costs by 10% annually compared to older, less efficient supplies. During a 10ms AC line dropout (common in industrial grids), the module maintained output power—preventing a 30-minute production halt.

In water treatment (small municipal plants), GE IC693PWR330G powers a 90-30 system with a GE IC693CPU364 CPU, 3× GE IC693ALG221 modules (monitoring pH and chlorine levels), and 2× GE IC693DO106 modules (controlling chemical dosing pumps). Its conformal coating resists humidity (90% RH) and chemical vapors, while ATEX Zone 2 certification ensures safety in areas with occasional methane gas exposure. The module’s red fault LED alerted technicians to an overcurrent event (caused by a faulty pump), enabling a 45-minute repair before the issue affected water quality.

GE IC693PWR330G

Related Model Recommendations

GE IC693PWR320G: 80W 90-30 Power Supply – Low-power alternative to GE IC693PWR330G for small 90-30 systems (e.g., 1 CPU + 2 I/O modules) where 120W is unnecessary.

GE IC693CHS390: 9-Slot 90-30 Chassis – Houses GE IC693PWR330G (Slot 0) and 90-30 modules, ideal for mid-scale systems with 5–8 I/O modules.

GE IC693CPU374: 90-30 High-Performance CPU – Primary load for GE IC693PWR330G’s +5V DC output (8A typical) for control logic execution.

GE IC693ALG221: 90-30 Analog Input Module – Uses GE IC693PWR330G’s ±12V DC auxiliary outputs for precise analog signal measurement (temperature, pressure).

GE IC693TCM302: 90-30 Serial Communication Module – Powered by GE IC693PWR330G’s +12V DC output, enabling Modbus RTU communication with sensors/scanners.

GE IC693DI201: 90-30 Digital Input Module – Connects to photoelectric sensors, powered by GE IC693PWR330G’s +5V DC output for package detection or machine safety.

GE IC693DO106: 90-30 Digital Output Module – Controls motors/valves, drawing power from GE IC693PWR330G’s +5V DC output (2A per module max).

GE IC693ACC001: Power Supply Test Tool – Verifies GE IC693PWR330G’s output voltages, protection features, and power factor during maintenance.

GE IC693FAN001: 90-30 Chassis Fan – Complements GE IC693PWR330G in high-temperature environments (>50°C), ensuring continuous 120W output by cooling the chassis.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC693PWR330G, confirm compatibility with the 90-30 chassis (e.g., GE IC693CHS390) and that Slot 0 (dedicated power slot) is empty. Ensure the environment meets 0°C–+60°C and 5%–95% RH (non-condensing); avoid mounting near heat sources (e.g., high-power resistors) or EMI emitters (e.g., variable-speed drives). Required tools: Torque screwdriver (0.5–0.8 N·m), wire strippers (10–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Disconnect AC/DC input power; apply lockout/tagout per site safety protocols to prevent electrical shock.

Slide GE IC693PWR330G into 90-30 Chassis Slot 0 until it engages the backplane, then secure with the chassis locking screw (torque to 0.6 N·m). Connect input power to the removable terminal block: for AC, wire L (line), N (neutral), and PE (ground); for DC, wire +, –, and PE (verify polarity to avoid damage). Power on the chassis; check LEDs: green (input present, +5V/+12V/-12V active), no red (fault). Use a multimeter to confirm output voltages (+5V ±0.1V, +12V ±0.2V, -12V ±0.2V) via the chassis test points.

Maintenance suggestions: For daily use, inspect GE IC693PWR330G’s LEDs—red LED indicates a fault (reset by cycling input power for overcurrent; address overheating by cleaning chassis vents). Every 6 months, clean the module with compressed air (remove dust from vents and terminal block) and retighten input power connections (torque to 0.6 N·m). Annually, test protection features: simulate a short-circuit on the +5V output (ensure the red LED illuminates and output cuts off); verify thermal shutdown by heating the module to 70°C (ensure auto-recovery when cooled). Replace with GE-approved GE IC693PWR330G spares—third-party supplies may not match 90-30 backplane pinouts or protection levels.

Service and Guarantee Commitment

GE IC693PWR330G is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, power output stability, and protection features under normal industrial use. If GE IC693PWR330G fails within the warranty period (e.g., overvoltage protection malfunction, output current drift, or conformal coating damage), GE will repair or replace the module free of charge, including expedited shipping (2–3 business days) for critical systems (e.g., water treatment, 24/7 manufacturing).

GE provides 24/7 online resources for GE IC693PWR330G (installation guides, troubleshooting flowcharts, MTBF data) and email/phone support during business hours. For customers with large 90-30 deployments (10+ systems), GE offers on-site power system audits—verifying GE IC693PWR330G’s compatibility with module loads, optimizing input power settings to maximize efficiency, and training maintenance teams on fault diagnosis.

To extend the module’s lifecycle, GE recommends storing unused GE IC693PWR330G units in a dry, temperature-controlled environment (-20°C to +50°C) and protecting the terminal block with a dust cap (GE part #IC693ACC002) during storage. This commitment reflects GE’s confidence in GE IC693PWR330G’s durability, ensuring it delivers reliable power for 90-30 systems for 10+ years.