Description

Product Overview

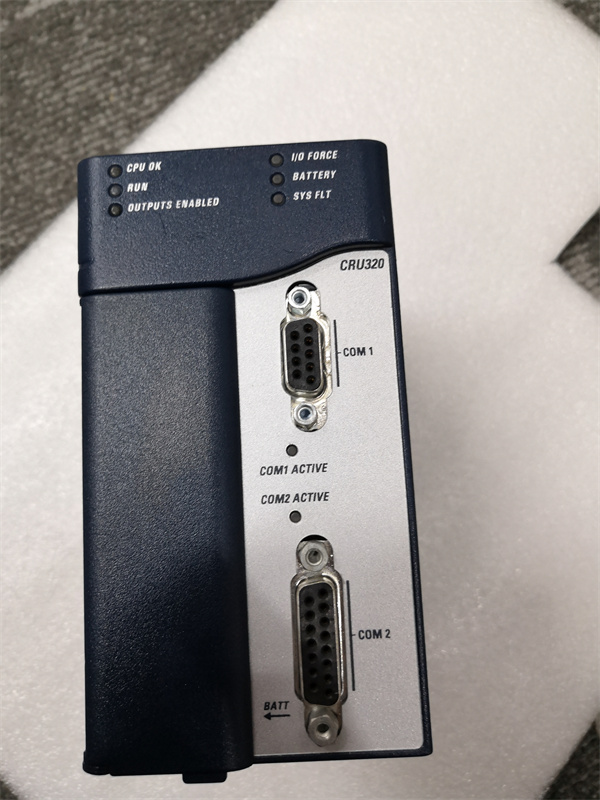

The GE IC695CRU320 – BB is a high – performance programmable automation controller (PAC) that belongs to the PACSystems RX3i product line. As a crucial component in industrial automation systems, it offers reliable and efficient control capabilities, making it an ideal choice for a wide range of manufacturing and industrial applications.

This controller module is designed to handle complex control tasks with ease. It features a 1 GHz Celeron – M microprocessor, which enables it to execute control logic and computational tasks at a high speed. With 64 MB of non – volatile flash memory and 64 MB of battery – backed random – access memory (RAM), the IC695CRU320 – BB can store extensive control programs and data, ensuring seamless operation even during power outages. It also supports both local and remote expansion racks, providing flexibility for system integration and allowing for the addition of more I/O modules as the system requirements grow.

The GE IC695CRU320 – BB is especially well – suited for applications that require high availability, as it supports hot standby redundancy. In a redundant configuration, two controllers work in tandem, with one acting as the active controller and the other as the standby. If the active controller fails, the standby controller can take over within a very short time, typically within 3.133 milliseconds, minimizing system downtime and ensuring continuous operation of critical processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695CRU320 – BB |

| Manufacturer | GE |

| Product Type | Programmable Automation Controller (PAC) |

| Processor | 1 GHz Celeron – M microprocessor |

| Memory Capacity | 64 MB non – volatile flash memory, 64 MB battery – backed RAM |

| I/O Channels | Up to 256 inputs/outputs (expandable) |

| Operating Voltage | 5 VDC |

| Operating Temperature Range | – 40 °C to 85 °C |

| Certifications | UL, CE, RoHS compliant |

| Redundancy Support | Hot standby redundancy |

| Serial Ports | 2 (supporting RS – 232 and RS – 485) |

| Serial Protocols | SNP, serial I/O, Modbus slave and master |

| Embedded Comms | RS – 232, RS – 486 |

| Programmable Blocks | Up to 512, each up to 128 KB in size |

| Synchronization Links | Supports up to two IC695RMX128/228 for data transfer up to 2 MB |

IC695CRU320-BB

Main Features and Advantages

High – Performance Processing

The 1 GHz Celeron – M microprocessor in the GE IC695CRU320 – BB provides rapid processing speeds, allowing it to handle complex control algorithms and large amounts of data efficiently. This high – performance processing power ensures that the controller can respond quickly to input signals and execute control actions in a timely manner, which is essential for applications where real – time control is crucial, such as high – speed manufacturing lines.

Redundancy for High Availability

With its support for hot standby redundancy, the IC695CRU320 – BB significantly enhances system reliability. In critical industrial processes, such as those in power generation or oil and gas production, system downtime can result in substantial losses. The redundant configuration of this controller ensures that if one unit fails, the other can immediately take over, minimizing disruptions and maintaining continuous operation.

Memory and Storage Capabilities

The combination of 64 MB non – volatile flash memory and 64 MB battery – backed RAM offers ample space for storing control programs, data, and configurations. The non – volatile flash memory retains data even during power failures, while the battery – backed RAM ensures that any in – progress operations are not lost. This large memory capacity enables the controller to handle complex applications with numerous control functions and data – intensive operations.

Versatile Communication Options

Equipped with two serial ports supporting RS – 232 and RS – 485, along with multiple serial protocols like SNP, serial I/O, and Modbus (both as slave and master), the GE IC695CRU320 – BB can easily communicate with a wide range of other devices in an industrial network. This versatility in communication allows for seamless integration with sensors, actuators, HMIs, and other controllers, enabling efficient data exchange and system – wide control.

IC695CRU320-BB

Application Field

Industrial Automation in Manufacturing

In manufacturing plants, the GE IC695CRU320 – BB can be used to control automated production lines. It can manage the operation of robotic arms, conveyor belts, and other machinery, ensuring precise coordination and high – speed production. For example, in an automotive manufacturing plant, the controller can regulate the movement of robotic arms that assemble car parts, ensuring accurate and efficient assembly. It can also monitor and control the speed of conveyor belts to ensure a smooth flow of components through the production process.

Power Generation and Distribution

In power plants, whether they are thermal, hydro, or wind – powered, the IC695CRU320 – BB plays a vital role in controlling various processes. It can manage the operation of generators, ensuring stable power output by regulating factors such as fuel supply, turbine speed, and voltage. In power distribution systems, the controller can be used to monitor and control the switching of circuit breakers, transformers, and other electrical equipment, ensuring reliable power supply to consumers.

Oil and Gas Industry

In the oil and gas industry, the GE IC695CRU320 – BB is used to control the operation of oil refineries, gas processing plants, and pipelines. It can monitor and control the flow of oil and gas, adjust the pressure and temperature in processing units, and ensure the safe and efficient operation of pumps, compressors, and other equipment. For instance, in an oil refinery, the controller can regulate the distillation process, ensuring the production of high – quality fuels and other petroleum products.

Related Products

- GE IC695RMX128/228: These are synchronization link modules that work in conjunction with the IC695CRU320 – BB. They enable data transfer between redundant controllers, ensuring that both the active and standby controllers have the same information, which is crucial for seamless failover in a redundant system.

- GE IC695 series I/O modules: Modules like the IC695MDL645 (digital input module) and IC695MDL754 (digital output module) can be connected to the IC695CRU320 – BB. They expand the controller’s input and output capabilities, allowing it to interface with a wider range of sensors and actuators in an industrial system.

- GE Proficy Machine Edition: This is the software development environment for GE controllers, including the IC695CRU320 – BB. It provides a platform for creating, running, and diagnosing operator interface, motion, and control applications, making it easier for engineers to program and manage the controller.

- GE IC693CRU320: This is another controller in the GE product line. While the IC695CRU320 – BB offers advanced features like higher processing speed and redundancy support, the IC693CRU320 may be more suitable for less complex applications or those with lower performance requirements.

- GE IC697CRU320: A more advanced version in terms of processing power and features compared to the IC695CRU320 – BB. It may be used in applications that demand even higher performance, such as large – scale industrial complexes with extremely complex control requirements.

Installation and Maintenance

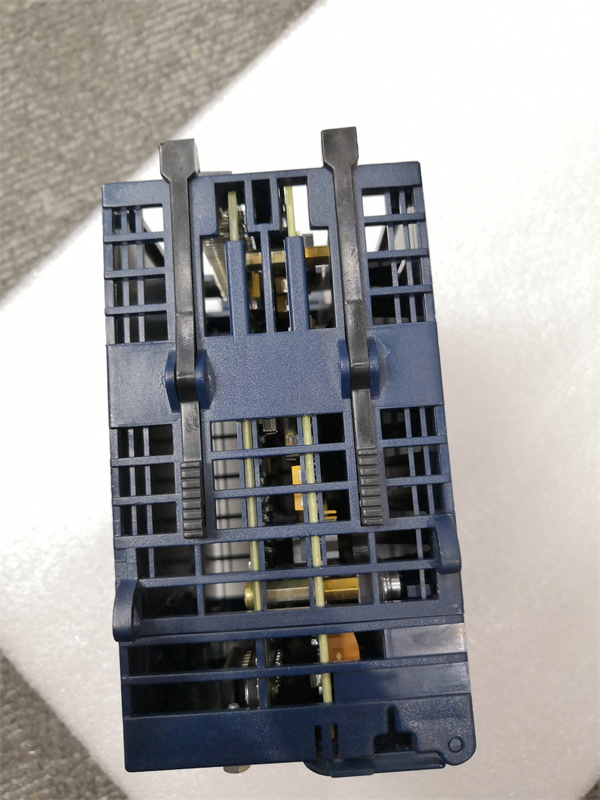

Pre – installation preparation: Before installing the GE IC695CRU320 – BB, ensure that the power to the entire system is turned off to prevent electrical hazards. Check the physical condition of the module for any signs of damage during transit. Verify that the module is compatible with the existing system components, including the power supply, backplane, and other I/O modules. Follow the detailed installation guidelines provided in the product manual to correctly mount the module on the RX3i backplane, ensuring proper alignment and secure fastening.

Maintenance recommendations: Regularly check the IC695CRU320 – BB for any signs of overheating, such as discoloration of the module or components. Monitor the status of the LEDs on the module, as they provide valuable information about the module’s operation, including power status, communication activity, and any error conditions. Periodically update the controller’s firmware to ensure it has the latest features and bug fixes. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IC695CRU320 – BB. The module is manufactured to the highest industry standards, undergoing rigorous testing procedures to ensure its reliability and performance. In the unlikely event of a defect in materials or workmanship during the warranty period, GE offers comprehensive repair or replacement services. Their dedicated technical support team is available around the clock to assist customers with any installation – related queries, operational issues, or troubleshooting needs. This commitment to quality and customer support reflects GE’s confidence in the IC695CRU320 – BB and its ability to meet the demanding requirements of industrial applications, providing customers with peace of mind and long – term value.