Description

Detailed Parameter Table

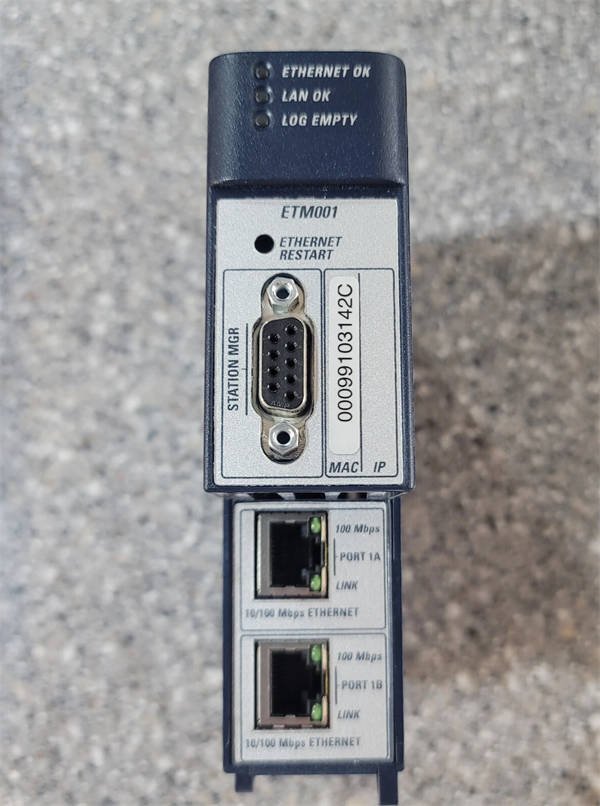

| Parameter Name | Parameter Value |

| Product model | IC695ETM001-EM |

| Manufacturer | GE (General Electric) Industrial Solutions |

| Product category | PACSystems RX3i Enhanced Industrial Ethernet Communication Module |

| Supported communication protocols | Ethernet/IP (Adapter/Scanner), Modbus TCP/IP (Client/Server), TCP/IP, UDP, DNP3.0 over TCP/IP, Secure MQTT |

| Ethernet port configuration | 2 x 10/100/1000 Base-TX Gigabit Ethernet RJ45 ports (auto-negotiation, full/half-duplex; MDI/MDI-X auto-crossover; galvanic isolation) |

| Compatibility | GE PACSystems RX3i controllers (IC695CPU310, IC695CPU330, IC695CPU350); works with RX3i 5/10/15/20-slot racks (IC698CRE005CA, IC698CRE020CA) |

| Data transfer rate | Up to 1 Gbps (Gigabit Ethernet); 100 Mbps backplane communication with RX3i CPU |

| Redundancy support | Media Redundancy Protocol (MRP) + Parallel Redundancy Protocol (PRP); failover time < 20 ms |

| Security features | 802.1X authentication, SSL/TLS encryption, IPsec VPN, firewall (port filtering, access control lists) |

| Physical dimensions | 44.5 mm (W) × 101.6 mm (H) × 152.4 mm (D) (RX3i rack-compatible) |

| Power consumption | 5 V DC, 1.5 A (powered via RX3i main rack backplane) |

| Environmental operating temp | -40°C to 70°C (-40°F to 158°F) |

| Environmental storage temp | -40°C to 85°C (-40°F to 185°F) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing); IP30 protection rating |

| Vibration resistance | 15 g peak (10 Hz to 2000 Hz) per IEC 60068-2-6 |

| Shock resistance | 50 g peak (11 ms duration) per IEC 60068-2-27 |

| Compliance standards | UL 508, CSA C22.2 No. 14, IEC 61131-2, CE marked, FCC Part 15 Class A, IEEE 802.3ab, ATEX Zone 2, IECEx |

| Diagnostic features | LED indicators (power, backplane, port link/activity, redundancy, security status); built-in self-test (BIST); error logging via Proficy Machine Edition |

GE IC695ETM001-EM

Product Introduction

The GE IC695ETM001-EM is an enhanced Gigabit Ethernet communication module designed for GE’s PACSystems RX3i platform, engineered to address the most demanding industrial connectivity needs—from harsh environmental resilience to enterprise-grade security. As an advanced variant of modules like the IC695ETM001-GT, it serves as a robust connectivity hub between RX3i controllers (such as the high-performance IC695CPU350) and diverse industrial networks, enabling seamless data exchange across modern and legacy devices.

Unlike standard Ethernet modules, the GE IC695ETM001-EM integrates dual redundancy protocols (MRP + PRP) for near-zero downtime and a comprehensive security suite to protect against cyber threats—critical for industries like oil and gas, power generation, and critical infrastructure. Its extended environmental range (-40°C to 70°C) and IP30 rating make it suitable for outdoor substations, offshore platforms, and extreme-temperature manufacturing facilities. By integrating directly with RX3i racks (e.g., IC698CRE020CA) via the backplane, the GE IC695ETM001-EM eliminates external wiring complexity, while its support for Secure MQTT enables seamless integration with industrial IoT (IIoT) platforms—making it a future-proof solution for smart factories and digital transformation initiatives.

Core Advantages and Technical Highlights

Dual redundancy protocols for ultra-reliable operation: The GE IC695ETM001-EM sets itself apart with simultaneous support for MRP (Media Redundancy Protocol) and PRP (Parallel Redundancy Protocol)—a step up from the IC695ETM001-GT’s single MRP support. PRP creates two independent network paths, ensuring data is transmitted over both links simultaneously; if one path fails, the other continues without interruption, achieving a failover time of less than 20 ms. This is critical for mission-critical applications like nuclear power plant control or chemical batch processing, where even 50 ms of downtime can lead to safety risks or millions in production losses. For example, in an offshore wind farm, the module ensures continuous communication between RX3i controllers and turbine sensors—even if a storm damages one network cable.

Enterprise-grade security for cyber resilience: The GE IC695ETM001-EM includes a layered security suite unmatched by standard RX3i Ethernet modules. It supports 802.1X authentication (to verify device identity before network access), SSL/TLS encryption (for secure data transmission between the module and SCADA systems), and IPsec VPN (to protect remote communication with control centers). Its built-in firewall allows administrators to define access control lists (ACLs) and filter ports—blocking unauthorized traffic like malicious cyberattacks. In smart grid applications, this security ensures compliance with NERC CIP standards, preventing unauthorized access to power distribution data that could disrupt the grid. Unlike the IC695ETM001-GT, which requires an external security module (IC695SEC001), the GE IC695ETM001-EM integrates these features natively, reducing system cost and complexity.

Extended environmental resilience for harsh conditions: With an operating temperature range of -40°C to 70°C (vs. -20°C to 60°C for the IC695ETM001-GT) and IP30 protection (vs. IP20), the GE IC695ETM001-EM thrives in extreme environments. It resists vibration up to 15 g peak (vs. 10 g) and shock up to 50 g peak (vs. 30 g), making it suitable for heavy-industry settings like mining operations (where equipment vibration is intense) or Arctic oil pipelines (where temperatures drop below -40°C). The module’s galvanically isolated Ethernet ports protect against electrical surges—common in industrial facilities with high-voltage machinery—preventing damage to the RX3i controller and connected devices. ATEX Zone 2 and IECEx certifications further allow use in hazardous areas with flammable gases, such as refineries or chemical plants.

IIoT-ready with Secure MQTT support: The GE IC695ETM001-EM natively supports Secure MQTT (Message Queuing Telemetry Transport), a lightweight protocol optimized for IIoT data transmission. This allows the module to send real-time sensor data, equipment status, and diagnostic information directly to cloud-based IIoT platforms (e.g., GE Predix) without additional gateways. For example, in a smart manufacturing plant, the module can stream production line data to the cloud, enabling predictive maintenance algorithms to detect equipment wear before failures occur. Unlike the IC695ETM001-GT, which requires custom software to integrate with IIoT systems, the GE IC695ETM001-EM simplifies this process, accelerating digital transformation for RX3i users.

Typical Application Scenarios

Offshore oil and gas platforms: Offshore platforms demand rugged, secure communication solutions, and the GE IC695ETM001-EM meets this need with its ATEX Zone 2 certification, IP30 rating, and -40°C to 70°C operating range. It connects PACSystems RX3i controllers to subsea sensors (measuring pressure, flow rate, and temperature) via Ethernet/IP, while PRP redundancy ensures communication remains intact during storms or cable damage. The module’s SSL/TLS encryption protects sensitive data (e.g., well production metrics) transmitted to onshore control centers, preventing cyber threats. Its galvanic isolation shields against electrical surges from platform machinery, ensuring the IC695CPU350 and connected devices remain operational—critical for avoiding costly well shutdowns.

Arctic power substations: In Arctic regions, where temperatures drop to -40°C, the GE IC695ETM001-EM enables reliable communication between RX3i controllers and power distribution equipment. Its extended temperature tolerance ensures it functions in freezing conditions, while MRP/PRP redundancy prevents outages if ice damage disrupts network links. The module’s DNP3.0 over TCP/IP support allows it to collect data from legacy power meters, and Secure MQTT streams this data to a cloud platform for grid load balancing. The built-in firewall blocks unauthorized access from remote locations, complying with strict utility security standards and protecting the substation from cyberattacks.

Mining operations: Mining facilities face intense vibration, dust, and temperature fluctuations—challenges the GE IC695ETM001-EM addresses with its 15 g vibration resistance, IP30 dust protection, and wide operating range. It connects RX3i controllers to Ethernet/IP-enabled mining equipment (e.g., conveyor belts, drill rigs) and Modbus TCP/IP sensors (monitoring dust levels and equipment temperature). PRP redundancy ensures continuous communication even if a network cable is damaged by heavy machinery, while 802.1X authentication prevents unauthorized devices from accessing the network. The module’s ability to operate in temperatures up to 70°C (common in underground mines) eliminates the need for expensive climate control, reducing operational costs.

GE IC695ETM001-EM

Related Model Recommendations

GE IC695ETM001-GT: Standard Gigabit Ethernet module for RX3i, the predecessor to GE IC695ETM001-EM. The IC695ETM001-EM adds security, dual redundancy, and extended environmental support—ideal for upgrading systems from basic to enhanced connectivity.

GE IC695CPU350: High-performance RX3i CPU module, optimized for use with GE IC695ETM001-EM. It leverages the module’s dual redundancy and security features to manage complex control logic in mission-critical applications.

GE IC698CRE020CA: 20-slot RX3i rack, compatible with GE IC695ETM001-EM. Provides space for the module, CPU, and I/O modules in large-scale systems like offshore platforms or mining facilities.

GE IC695PWR330: High-output power supply module for RX3i racks, recommended for systems with GE IC695ETM001-EM (1.5 A power consumption). Delivers stable 5 V DC to support the module’s enhanced features.

GE IC695MDL754: 16-channel digital I/O module, paired with GE IC695ETM001-EM. Sends sensor data to the CPU, which transmits aggregated data to SCADA systems via the module’s secure Ethernet links.

GE IC695CMM320: Profinet communication module, complementary to GE IC695ETM001-EM. For systems with Profinet-enabled devices (e.g., Siemens mining equipment), it works with the module to unify multi-protocol communication.

GE IC695SEC001: External security module for RX3i, redundant with GE IC695ETM001-EM’s native security. Useful for adding an extra layer of protection in ultra-critical applications like nuclear power plants.

GE IC698BEM001: RX3i backplane expansion module, compatible with GE IC695ETM001-EM. Extends the backplane to remote racks (e.g., in Arctic substations), allowing the module to be installed near equipment while maintaining communication with the CPU.

GE IC695DNP001: DNP3.0 communication module, supplementing GE IC695ETM001-EM’s DNP3.0 support. Adds advanced features like event logging for large-scale power distribution systems.

GE IC695HSC304: 4-channel high-speed counter module, paired with GE IC695ETM001-EM. Generates pulse data (e.g., drill rig speed) that is transmitted to IIoT platforms via the module’s Secure MQTT support.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC695ETM001-EM, power off the RX3i rack (e.g., IC698CRE020CA) and wear an anti-static wristband. Ensure the rack has an available slot (slots 2-20) and is powered by a compatible supply (GE IC695PWR330) to support 1.5 A. Gather tools: screwdriver, torque wrench (3.5 N·m for rack screws), Cat6a Ethernet cables (for Gigabit speed), and a PC with Proficy Machine Edition (v10.0+ for security configuration). Verify the environment meets specs: -40°C to 70°C, 5%-95% humidity, and no direct exposure to liquids (IP30 protection). For hazardous areas (ATEX Zone 2), ensure installation complies with local safety regulations (e.g., use certified cables).

Commissioning steps:

Align GE IC695ETM001-EM with the rack slot, slide it into place, and secure with screws (torque to 3.5 N·m). Ensure the backplane connector is fully seated to avoid communication issues.

Power on the rack and confirm LEDs: green (power), blue (backplane communication with IC695CPU350), solid green (Ethernet port link), blinking amber (activity), and green (security status). Red LEDs indicate faults (e.g., PRP ring break, SSL certificate error).

Connect the PC to the module’s Ethernet port via Cat6a cable, launch Proficy Machine Edition, and detect the module using “Module Discovery.” Update the module’s firmware to the latest version (critical for security patches).

Configure core features: Assign a static IP address, enable MRP/PRP (define ring topology for MRP, dual links for PRP), and set up security (upload SSL certificates, configure 802.1X authentication, and define firewall ACLs). Map device data to the CPU’s memory (e.g., link a pressure sensor’s Modbus register to Input Register 40001).

Test functionality: Send a test command from the CPU to a device (e.g., “start drill rig”) and verify the module forwards it within 1 ms. Test redundancy by disconnecting one PRP link—confirm failover in < 20 ms. Test security by attempting unauthorized access (e.g., a non-802.1X device)—ensure the firewall blocks it.

Maintenance suggestions:

Daily: Inspect LEDs—pay special attention to security and redundancy status. A yellow security LED signals expired SSL certificates; red redundancy LED indicates a link failure.

Weekly: Clean the module’s vents and Ethernet ports with compressed air (low pressure, < 50 psi) to remove dust (critical for IP30 protection). Check Cat6a cables for damage (e.g., cuts, bent pins) and replace if necessary.

Monthly: Use Proficy Machine Edition to run a diagnostic scan—check for protocol errors, PRP/MRP status, and security logs (e.g., failed 802.1X attempts). Back up the module’s configuration (including security certificates) to an encrypted external drive.

Quarterly: Update firmware and security patches via GE’s support portal—critical for addressing new cyber threats. Test redundancy by intentionally breaking a PRP link and verifying failover time with a network analyzer.

Annually: Inspect the module for physical damage (e.g., corrosion on connectors) and verify environmental compliance with a data logger. For ATEX Zone 2 applications, have a third-party inspector confirm compliance with safety standards.

Service and Guarantee Commitment

The GE IC695ETM001-EM is backed by a 5-year standard manufacturer’s warranty from GE Industrial Solutions—longer than the 3-year warranty of the IC695ETM001-GT—covering defects in materials, workmanship, and enhanced features (redundancy, security, environmental resilience) under normal industrial use. During the warranty period, if the module fails to meet specs (e.g., PRP failover > 20 ms, security breach due to module defect, or failure in -40°C conditions), GE will repair or replace it free of charge, including expedited shipping (24-hour delivery for