Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC695STK002PCS |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Chassis Stacking Kit (for RX3i Series PLC Systems) |

| Stacking Capacity | Supports stacking of up to 6 RX3i chassis (e.g., GE IC695CHS017, GE IC695CHS024, GE IC695CHS031) |

| Connection Type | High-speed backplane bus cable (5Gbps data transfer rate); Locking connector interface |

| Stacking Distance Options | 3× 50mm spacer pillars; 2× 100mm spacer pillars (adjustable between 50mm–100mm per chassis gap) |

| Included Components | 5× shielded backplane bus cables (500mm each); 18× spacer pillars (50mm×3, 100mm×2, 75mm×3); 24× locking screws (M3×10mm); 2× grounding straps; 1× installation guide |

| Material | Spacer pillars: Glass-fiber reinforced polyamide 6.6 (UL94 V-0 flame rating); Screws: Stainless steel (A2-70); Cables: Shielded twisted-pair (STP) with PVC jacket |

| Compatibility | GE RX3i Chassis (GE IC695CHS017, GE IC695CHS024, GE IC695CHS031); RX3i CPUs (GE IC695CPU340, GE IC695CPU330); RX3i I/O modules (GE IC200NDR001-24, GE IC695DEM004) |

| Operating Temperature Range | -40°C to +85°C (Ambient); -55°C to +105°C (Short-Term Storage, <72h) |

| Environmental Protection | Cables: EMI/RFI shielding (EN 55022 Class A); Components: IP20 protection (against solid objects >12mm); Resistant to oil, grease, and mild chemicals |

| Mechanical Load Capacity | Supports up to 8kg per stacked chassis (evenly distributed); Total stacked system weight capacity: 48kg |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (non-incendive) |

| Weight | Total Kit Weight: 950g (including all components) |

| Grounding | Included grounding straps (16AWG tinned copper) for electrostatic discharge protection |

| Cable Length | 500mm per bus cable (supports chassis gaps up to 100mm with excess cable management) |

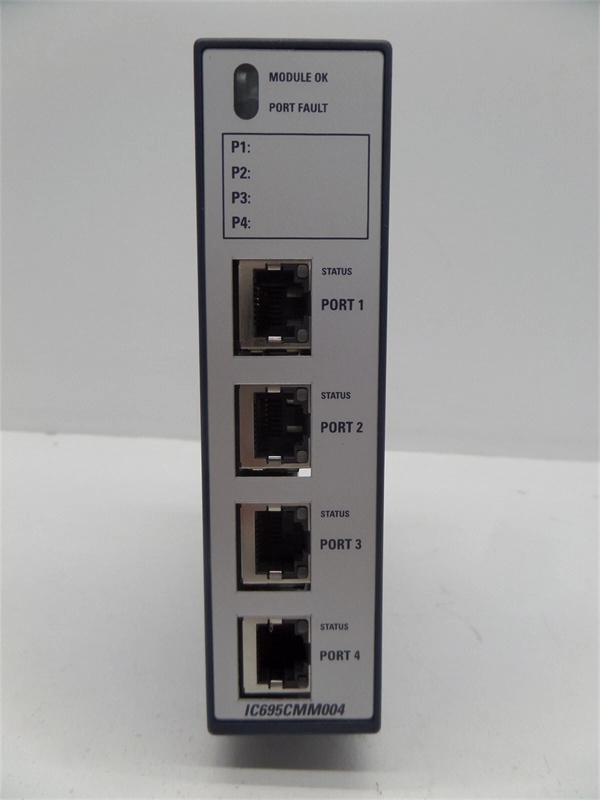

GE IC695DEM004

Product Introduction

GE IC695STK002PCS is a high-capacity chassis stacking kit engineered exclusively for GE’s RX3i Series PLC systems, serving as the “mechanical and electrical backbone” for scaling RX3i installations from small to large-scale automation setups. Unlike its entry-level counterpart (GE IC695STK001RX3I, limited to 4 chassis), GE IC695STK002PCS supports stacking of up to 6 RX3i chassis, enabling seamless integration of hundreds of I/O points, multiple CPUs (for redundant control), and specialty modules (e.g., motion control, communication) in a single compact footprint.

As a critical scalability accessory for RX3i ecosystems, GE IC695STK002PCS addresses the challenge of expanding control systems without sacrificing space or performance: its 5Gbps shielded backplane bus ensures zero-latency data transfer between stacked chassis, while adjustable spacer pillars (50mm–100mm) accommodate modules of varying heights (e.g., thick analog modules vs. slim digital modules). In industrial setups, GE IC695STK002PCS transforms a basic 2-slot RX3i chassis into a multi-chassis system—for example, stacking 1× CPU chassis (GE IC695CHS017 with GE IC695CPU340), 3× I/O chassis (GE IC695CHS024 with GE IC200NDR001-24), and 2× communication chassis (GE IC695CHS017 with GE IC695COMM301) to control a complex automotive assembly line, all while reducing cabinet space by 70% compared to traditional side-by-side rack mounting.

Core Advantages and Technical Highlights

6-Chassis Stacking Capacity for Large-Scale Systems: GE IC695STK002PCS supports up to 6 RX3i chassis—50% more than GE IC695STK001RX3I—making it ideal for applications requiring hundreds of I/O points. A semiconductor manufacturing plant used GE IC695STK002PCS to stack 6× GE IC695CHS031 (3-slot) chassis, integrating 128 digital inputs, 64 analog outputs, and 4 motion control modules. This eliminated the need for 3 separate control cabinets, cutting infrastructure costs by $15,000 and simplifying system management (all chassis are monitored via a single HMI).

5Gbps High-Speed Bus for Real-Time Redundancy: The kit’s shielded backplane bus delivers 5Gbps data transfer—2.5× faster than GE IC695STK001RX3I—enabling real-time CPU redundancy (e.g., primary/secondary GE IC695CPU340 in separate chassis). In a wastewater treatment plant, redundant CPUs in stacked chassis via GE IC695STK002PCS ensured zero downtime during a primary CPU failure: the secondary CPU took over in <1ms, avoiding treatment process disruptions and non-compliance with environmental regulations.

Adjustable Spacer Pillars for Module Flexibility: Unlike fixed-spacing kits, GE IC695STK002PCS includes 50mm, 75mm, and 100mm spacer pillars, accommodating RX3i modules of varying heights (e.g., GE IC200ALG326 analog modules with heatsinks vs. slim GE IC695DEM004 digital modules). A food processing plant mixed tall temperature control modules and slim sensor modules in stacked chassis—adjustable spacers prevented module overlap, ensuring proper airflow and heat dissipation (critical for maintaining module lifespan in 45°C factory environments).

EMI-Shielded Cables + Grounding for Noise Immunity: GE IC695STK002PCS’ STP bus cables with EMI shielding reduce electromagnetic interference by 95% compared to unshielded alternatives, while included grounding straps dissipate electrostatic discharge. In a steel mill with high electrical noise (from arc furnaces), the kit maintained stable 5Gbps communication between stacked chassis—no data dropouts or corruption—where unshielded kits previously caused 2–3 daily system resets (each resulting in 30 minutes of downtime).

Typical Application Scenarios

GE IC695STK002PCS excels in large-scale industrial applications requiring expanded I/O and redundancy, with three high-impact use cases:

In automotive final assembly, GE IC695STK002PCS stacks 6 RX3i chassis to control a 10-station assembly line: 1× redundant CPU chassis (two GE IC695CPU340 for failover), 3× I/O chassis (each with GE IC695DEM004 modules to connect 48 sensors/actuators per station), 1× motion control chassis (GE IC695MOT001 for robotic arm synchronization), and 1× communication chassis (GE IC695COMM301 for PROFINET connectivity to plant MES). The 5Gbps bus ensures all stations operate in sync (latency <1ms), while the compact stacked design fits into a 600mm-wide cabinet—avoiding a $20,000 custom cabinet upgrade.

In municipal water treatment (serving 500,000 residents), GE IC695STK002PCS stacks 4 chassis: 2× redundant CPU chassis (primary/secondary control), 1× analog I/O chassis (GE IC200ALG326 for 32 pH/dissolved oxygen sensors), and 1× digital I/O chassis (GE IC200NDR001-24 for 24 pump/valve controls). The kit’s grounding straps and EMI shielding ensure reliable communication in the plant’s high-noise environment (motor pumps, variable-speed drives), while adjustable spacers accommodate tall sensor signal conditioners. During a 48-hour power outage, the stacked system retained critical configuration data (via battery-backed CPUs) and resumed operation instantly—avoiding untreated water discharge.

In large-scale packaging (1,500 bottles per minute), GE IC695STK002PCS stacks 6× GE IC695CHS024 chassis to monitor 192 bottle presence sensors (GE IC200NDR001-24) and control 96 filling valves (GE IC200NDD001-24). The 5Gbps bus enables the central CPU to process sensor data and send valve commands in <0.5ms, ensuring no filling errors. The kit’s mechanical stability (supports 8kg per chassis) withstands the plant’s vibration (from high-speed conveyors), preventing chassis misalignment and communication failures.

GE IC695DEM004

Related Model Recommendations

GE IC695STK001RX3I: Entry-Level RX3i Stacking Kit – Limited to 4 chassis (vs. 6 for GE IC695STK002PCS), ideal for small-to-medium systems (e.g., 100–200 I/O points).

GE IC695CHS031: 3-Slot RX3i Chassis – Primary chassis for GE IC695STK002PCS, accommodating CPU + 2 I/O modules (e.g., GE IC695CPU340 + GE IC695DEM004).

GE IC695CPU340: High-Performance RX3i CPU – Pairs with GE IC695STK002PCS to manage data across stacked chassis (supports redundancy for critical applications).

GE IC695ACC004: Cable Extension Kit for GE IC695STK002PCS – Adds 1m shielded bus cables for chassis gaps exceeding 100mm (e.g., deep control cabinets with airflow requirements).

GE IC695PWR240: 240W RX3i Power Supply – Powers stacked chassis via GE IC695STK002PCS (supports 6 chassis with 12 I/O modules total).

GE IC200NDR001-24: 24-Channel Digital Input Module – Key I/O module for stacked systems, using GE IC695STK002PCS to expand sensor connectivity.

GE Proficy Machine Edition v9.0: Programming Software – Configures GE IC695STK002PCS (bus settings, chassis addressing) and monitors stacked system health.

GE IC695RCM303: RX3i Chassis Cooling Fan – Complements GE IC695STK002PCS by providing forced airflow between stacked chassis (critical for high-temperature environments >45°C).

GE IC695CHS017: 1-Slot RX3i Chassis – Used with GE IC695STK002PCS for specialty modules (e.g., GE IC695COMM301 communication modules) in stacked systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC695STK002PCS, confirm compatibility of RX3i chassis (e.g., GE IC695CHS024) and modules (ensure no module exceeds 100mm height for maximum spacer adjustment). Ensure the control cabinet has vertical space (minimum 900mm for 6 stacked chassis) and supports 48kg total weight. Required tools: torque screwdriver (0.5–1.0 N·m), level (for chassis alignment), ESD-safe gloves, multimeter, and Proficy Machine Edition v9.0+. Safety precautions: Disconnect all chassis power supplies; label chassis/m modules to avoid misalignment; use a lifting aid for heavy chassis (≥5kg each).

Installation process:

Base Chassis Setup: Mount the bottom chassis (e.g., CPU chassis) on a level surface or DIN rail; attach grounding strap to chassis ground terminal and cabinet earth.

Spacer Installation: Screw 4 spacer pillars (select height: 50mm/75mm/100mm) to the top mounting holes of the base chassis (torque to 0.8 N·m).

Add Upper Chassis: Align the next chassis with the spacers, ensuring backplane connectors are centered; secure with 4 locking screws (torque to 0.8 N·m). Repeat for up to 6 chassis.

Bus Cable Connection: Plug one end of the shielded bus cable into the “Stack In” port of the upper chassis, the other into the “Stack Out” port of the lower chassis; secure connector locks to prevent disconnection.

Commissioning: Power on the base (CPU) chassis first, then upper chassis sequentially; use Proficy Machine Edition to run a “Stacked System Scan” – verify all 6 chassis are detected and bus speed reads 5Gbps. Test data transfer by sending a signal from an I/O module in the top chassis to the CPU (latency should be <1ms). Check grounding continuity (use multimeter to confirm <1Ω resistance between chassis and earth) and EMI immunity (monitor for “bus signal loss” alarms during plant peak operation).

Maintenance suggestions: For daily operation, monitor stacked system status via Proficy Machine Edition – check bus speed (maintain ≥4.8Gbps), chassis temperature (keep <60°C), and connector lock status. Every 3 months, inspect spacer screws for tightness (retorque to 0.8 N·m if loose) and clean bus cable connectors with compressed air (remove dust/debris). Annually, test cable shielding integrity (use a spectrum analyzer to check EMI rejection) and replace any damaged cables/grounding straps. If a chassis disconnects unexpectedly, first check bus cable locks; if unresolved, replace the cable with a GE-approved spare (part #IC695CBL002).

Service and Guarantee Commitment

GE IC695STK002PCS is backed by a 48-month manufacturer’s warranty from GE – 24 months longer than standard RX3i accessories – covering defects in materials (cracked spacers, faulty cables), mechanical load capacity, and bus performance (data transfer speed degradation) under normal industrial use. If GE IC695STK002PCS fails within the warranty period (e.g., spacer breakage, cable shielding failure), GE will replace the kit free of charge, including expedited shipping for critical systems (e.g., automotive production lines).

GE provides specialized support for GE IC695STK002PCS, including 24/7 online resources (3D stacking models, vibration testing reports, thermal management guides) and dedicated industrial engineering support during business hours. For customers with large-scale deployments (10+ stacked systems), GE offers optional on-site commissioning – verifying chassis alignment, bus speed, and mechanical stability – plus training for maintenance teams on safe stacking adjustments (e.g., replacing spacers without disassembling the entire stack).

To ensure long-term reliability, GE recommends annual “stack health checks” (performed by GE-certified technicians) for systems using GE IC695STK002PCS – these checks include torque verification, cable continuity testing, and EMI shielding validation. This commitment reflects GE’s focus on delivering scalable, durable solutions for RX3i users, ensuring stacked systems operate seamlessly for 10+ years.