Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IC697ADC701 |

| Manufacturer | GE (General Electric) Fanuc Industrial Systems |

| Product category | 8-Channel Analog Input Module (for Series 90-70 PLC Systems) |

| Number of input channels | 8 (differential input; channel-to-channel isolation) |

| Input signal types | Configurable per channel: 0-10V DC, ±5V DC, 4-20mA DC, ±20mA DC |

| Input resolution | 12-bit (0-10V: 2.44mV/step; 4-20mA: 4μA/step) |

| Input accuracy | ±0.1% of full scale (at 25°C); ±0.25% over operating temperature range |

| Sampling rate | 10 samples per second per channel (simultaneous sampling across 8 channels) |

| Operating voltage | 5V DC (supplied by Series 90-70 backplane) |

| Backplane compatibility | GE Series 90-70 PLC backplanes (6-slot, 10-slot, 16-slot, 24-slot) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F) |

| Storage temperature range | -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions (W×H×D) | 89 mm × 133 mm × 191 mm (3.5 in × 5.2 in × 7.5 in) |

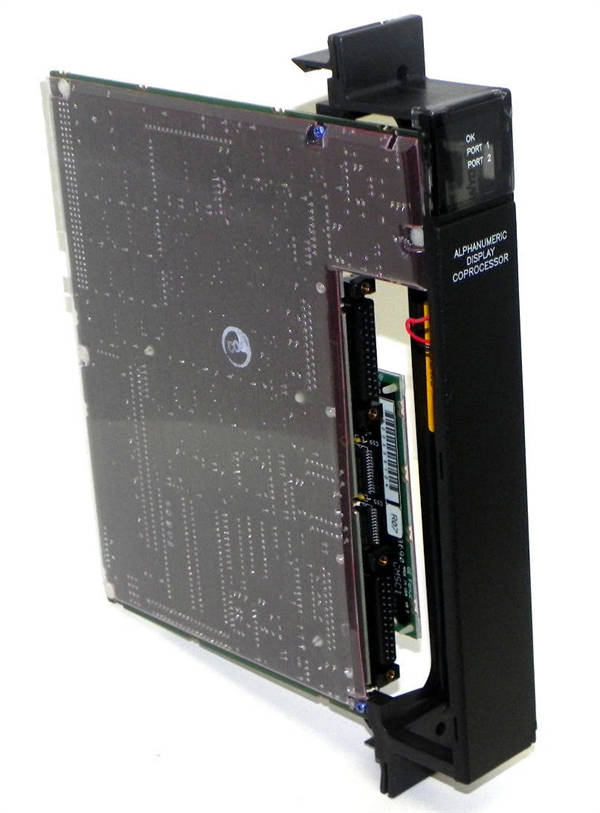

| Installation method | Backplane-mounted (plug-in design for Series 90-70 chassis; occupies 1 slot) |

| Protection features | Overvoltage protection (±30V DC per channel); ESD protection (±15kV air) |

| Compatible programming tools | GE Logicmaster 90-70, GE Proficy Machine Edition (Version 8.0+) |

GE IC697ADC701

Product Introduction

The GE IC697ADC701 is a high-precision 8-channel analog input module designed exclusively for GE’s Series 90-70 PLC systems, serving as the critical “signal bridge” between industrial analog sensors and the PLC’s central processing unit. As a core component of GE’s analog I/O ecosystem, the GE IC697ADC701 converts continuous analog signals (e.g., from temperature transmitters, pressure sensors, or flow meters) into digital data that the Series 90-70 PLC (e.g., GE IC697CPU788RR redundant CPU) can process—enabling real-time monitoring and control of critical process variables.

Each of the GE IC697ADC701’s 8 channels is independently configurable to support four common analog signal types (0-10V DC, ±5V DC, 4-20mA DC, ±20mA DC), eliminating the need for multiple single-type modules and simplifying system design. With 12-bit resolution and ±0.1% full-scale accuracy, the GE IC697ADC701 ensures minimal signal error—critical for applications like chemical processing or pharmaceutical manufacturing where even small deviations in sensor data can impact product quality. The module’s differential input design and channel-to-channel isolation also reduce electromagnetic interference (EMI) from nearby industrial equipment, ensuring stable signal collection in noisy environments.

Core Advantages and Technical Highlights

Flexible Multi-Signal Support: Unlike fixed-input analog modules, every channel of the GE IC697ADC701 can be individually programmed to accept 0-10V DC, ±5V DC, 4-20mA DC, or ±20mA DC signals via GE’s programming software. This flexibility allows the module to integrate with diverse sensor types in a single system—for example, monitoring 4-20mA pressure sensors, ±5V temperature transmitters, and 0-10V flow meters simultaneously. This eliminates the need to stock multiple module types, reducing inventory costs and simplifying maintenance.

High Accuracy and Stable Signal Conversion: The GE IC697ADC701 delivers 12-bit resolution, translating to fine-grained signal detection (e.g., 4μA increments for 4-20mA signals) that captures subtle changes in process variables—such as a 0.01 bar pressure fluctuation in a hydraulic system. Its ±0.1% accuracy (at 25°C) and temperature compensation (±0.25% over 0-60°C) prevent signal drift caused by environmental temperature changes, avoiding false alarms or incorrect control decisions. This level of precision makes it ideal for regulated industries like food and beverage, where strict process control is required.

Differential Input and Isolation: The GE IC697ADC701 uses differential inputs (instead of single-ended) to reject common-mode noise—electrical interference from motors, transformers, or power cables that often corrupts analog signals. Each channel is also isolated from the others and the backplane, preventing ground loops (a common cause of signal distortion in large industrial systems). For example, in an automotive factory, the module can collect data from sensors near welding robots (high EMI sources) without signal degradation, ensuring reliable monitoring of robot torque and position.

Simultaneous Sampling for Time-Sensitive Applications: The GE IC697ADC701 samples all 8 channels simultaneously at 10 samples per second, ensuring that data from related sensors (e.g., temperature and pressure in a boiler) is time-aligned. This is critical for applications like power generation, where synchronized data is needed to calculate real-time efficiency or detect abnormal operating conditions. Unlike sequential-sampling modules that introduce time lags between channels, the GE IC697ADC701’s simultaneous sampling ensures the PLC receives a coherent snapshot of the process at any given moment.

Typical Application Scenarios

The GE IC697ADC701 is widely used in process industries where accurate analog signal collection is essential. In chemical processing plants, for example, the GE IC697ADC701 connects to a GE IC697CPU788RR redundant PLC to monitor critical variables in reactor vessels: 4-20mA signals from pressure transmitters, ±5V signals from temperature RTDs (resistance temperature detectors), and 0-10V signals from level sensors. The module’s high accuracy ensures that chemical reaction temperatures stay within ±0.1°C of the setpoint, preventing product degradation, while its isolation protects against EMI from nearby 搅拌 motors. The PLC uses this data to adjust heating elements or chemical feed rates via GE IC697VAL348 analog output modules, maintaining process stability.

In water and wastewater treatment facilities, the GE IC697ADC701 collects data from analog sensors across filtration and disinfection systems: 4-20mA signals from pH transmitters (monitoring water acidity), 0-10V signals from chlorine residual sensors, and ±20mA signals from flow meters. Its differential input design rejects noise from pump motors, ensuring accurate pH readings (critical for avoiding corrosion in pipes or inadequate disinfection). The GE IC697ADC701 sends this data to the Series 90-70 PLC, which triggers alarms if pH levels exceed 8.5 or chlorine levels drop below 0.5 ppm—ensuring compliance with environmental regulations.

In manufacturing, the GE IC697ADC701 is used in plastic extrusion lines to monitor process variables like extruder barrel temperature (via ±5V RTD signals) and melt pressure (via 4-20mA pressure sensors). The module’s simultaneous sampling ensures that temperature and pressure data are synchronized, allowing the PLC to adjust heater power and screw speed in real time—preventing overheating (which causes plastic degradation) or under-pressure (which leads to uneven product thickness). The GE IC697ADC701’s overvoltage protection (±30V DC) also safeguards against sensor wiring errors, reducing module failure rates.

GE IC697ADC701

Related Model Recommendations

GE IC697ADC702: A 16-channel analog input module (expanded version of GE IC697ADC701), ideal for large-scale systems (e.g., refineries with 10+ analog sensors) requiring more input channels while retaining the same accuracy and signal flexibility.

GE IC697VAL348: 4-channel analog output module, paired with GE IC697ADC701 to create a complete analog I/O system—the ADC701 collects sensor data, and the VAL348 sends control signals to actuators (e.g., valves, drives).

GE IC697CPU788RR: Series 90-70 redundant CPU module, the “brain” that processes digital data from GE IC697ADC701 and executes control logic for mission-critical applications (e.g., power plants).

GE IC697BEM721: Genius Bus Controller Module, enables GE IC697ADC701 to communicate with the Series 90-70 PLC in distributed systems (e.g., multi-cell manufacturing plants with remote sensor arrays).

GE IC697PWR711: 5V/24V DC power supply module for Series 90-70 backplanes, provides stable 5V DC power to GE IC697ADC701—prevents voltage fluctuations that could cause signal conversion errors.

GE IC754CBF12CTD: 12-inch Proficy HMI touchscreen, compatible with GE IC697ADC701 via the Series 90-70 PLC—displays real-time analog data (e.g., temperature, pressure) for operator monitoring and troubleshooting.

GE IC697MEM711: Memory expansion module for Series 90-70 PLCs, provides additional storage for calibration data and historical sensor readings collected by GE IC697ADC701.

GE IC697IOL131: 8-channel digital input module, used alongside GE IC697ADC701 to monitor the status of analog sensor power supplies (e.g., detecting a failed 24V DC sensor power source) for comprehensive system diagnostics.

Installation, Commissioning and Maintenance Instructions

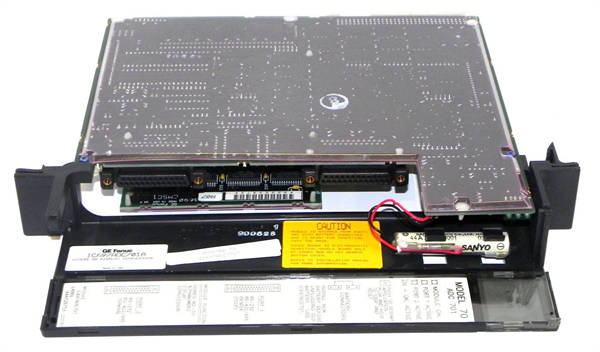

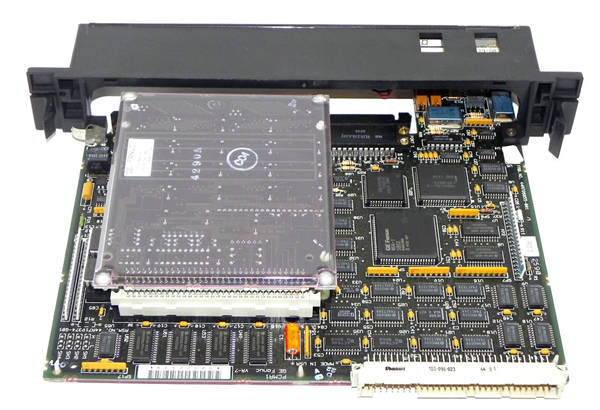

Installation preparation: Before installing GE IC697ADC701, power off the Series 90-70 backplane and wear an ESD wrist strap to protect the module’s signal conversion circuitry. Verify that the backplane is a Series 90-70 model (6-slot or larger) and that the 5V DC power supply (from GE IC697PWR711) is stable. Inspect the module’s backplane pins and input terminals for bending or corrosion—damaged pins can cause communication failures or short circuits. Align GE IC697ADC701 with the backplane’s guide rails, push firmly until it clicks into place, and secure it with the side locking screw to resist vibration. When wiring sensors, use shielded twisted-pair cables for analog signals (to reduce EMI) and ensure correct polarity—reverse polarity can trigger the module’s overvoltage protection and temporarily disable the channel.

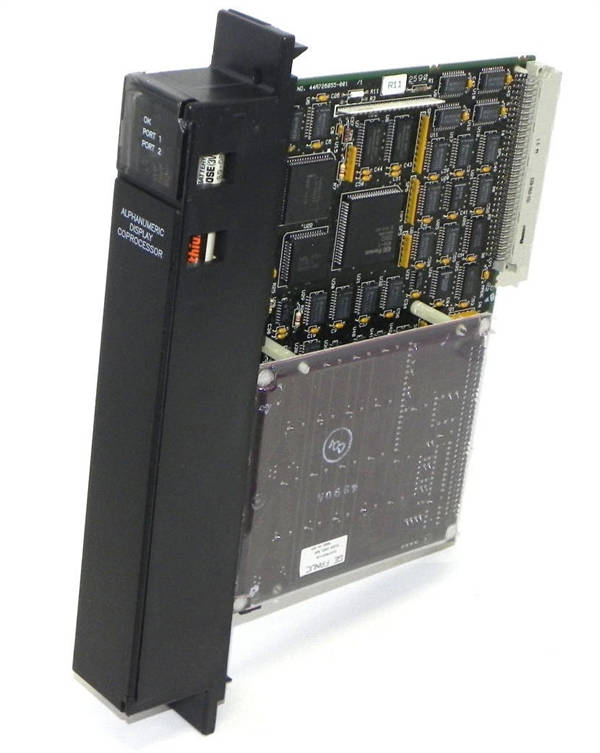

Maintenance suggestions: Conduct monthly checks of GE IC697ADC701’s LED status indicators—steady green per channel indicates normal signal reception, while red lights signal overvoltage or open-circuit faults (refer to the user manual for error codes). Every 6 months, calibrate the module via GE Proficy Machine Edition to maintain accuracy—use a precision signal generator to inject known values (e.g., 12mA for 4-20mA channels) and verify the PLC receives the correct digital output. Clean the module’s backplane connectors with a dry, lint-free cloth every 3 months to remove dust; avoid using liquids that could damage the terminals. If a channel fails to collect data, first check the sensor and wiring (e.g., open circuits, loose connections) before replacing the GE IC697ADC701—always use genuine GE modules to ensure compatibility with the Series 90-70 system.

Service and Guarantee Commitment

The GE IC697ADC701 comes with a 24-month warranty from the date of purchase, covering defects in materials, workmanship, and signal conversion performance under normal industrial use. GE’s global technical support team is available 24/7 via email, online chat, and phone to assist with installation, calibration, and troubleshooting—critical issues (e.g., module failure causing process data loss) receive a response within 4 hours, with detailed guidance on temporary workarounds to minimize downtime.

For customers in regulated industries (e.g., pharmaceuticals, oil and gas), GE offers customized service agreements tailored to GE IC697ADC701, including annual on-site calibration (performed by certified technicians), firmware updates (if applicable), and expedited spare parts delivery (48-hour global shipping for stock modules). All genuine GE IC697ADC701 units undergo rigorous testing—including 1,000+ hours of signal conversion accuracy checks and EMI immunity testing—to meet international standards (IEC 61131-2 for industrial control equipment, UL 508 for electrical safety). In the event of a warranty claim, GE provides a replacement module within 48 hours (for stock items) and offers technical support to restore system functionality quickly, reflecting our commitment to product reliability and customer operational continuity.