Description

Detailed Parameter Table

| Parameter Name | Parameter Value (Derived from Series 90-70 Analog Module Standards) |

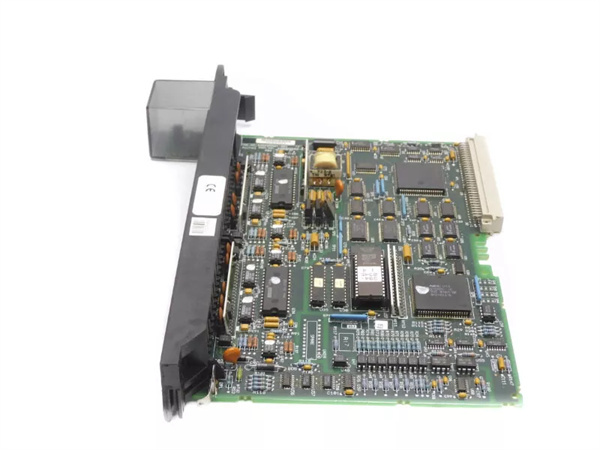

| Product model | GE IC697ALG320 |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | Mid-Range 8-Channel Analog Input Module (for Series 90-70 PLC) |

| Input channels | 8 independent channels (2 groups of 4 channels; configurable per group) |

| Input signal type | Voltage: ±10V, ±5V, 0-10V; Current: 4-20mA, 0-20mA; Thermocouple: J/K/T/E |

| Resolution | 16-bit (65536 discrete values) |

| Measurement accuracy | ±0.25% of full scale (FS) at 25°C; ±0.5% FS over operating temperature range |

| Sampling rate | 80 samples per second (per channel); sequential sampling across groups |

| Interface type | 16-pin terminal block (signal + ground); 3x status LEDs (Power, Group 1 Fault, Group 2 Fault) |

| Calibration mode | Auto-calibration (via Proficy Machine Edition); manual calibration option |

| Data buffer capacity | 4 kB total (2 kB per channel group) |

| Protection features | Overvoltage protection (±25V DC), ESD protection (±20kV contact), surge protection (2000V DC) |

| Isolation | Channel-to-channel optical isolation (2000 V AC rms for 1 minute); Channel-to-backplane isolation (2500 V AC rms) |

| Power supply | Derived from Series 90-70 chassis (5V DC logic power: 220mA max; no external power required) |

| Operating temperature range | -10°C to 70°C (14°F to 158°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 4-slot to 16-slot chassis; 1 slot required) |

| Diagnostic functions | Group-level fault LEDs (red = channel error), overrange/underrange flagging, calibration error logging |

| Compatibility | All Series 90-70 chassis (IC697CHS710, IC697CHS750, IC697CHS790), CPUs (IC697CPM915, IC697CPU770, IC697CPU780), power supplies (IC697PWR701, IC697PWR720) |

| Weight | 1.0 kg (2.20 lbs) |

| Compliance standards | UL 508, IEC 61131-2, CE, CSA C22.2 No. 14-13, IEC 61000-4-2 (ESD), IEC 61000-4-4 (EFT) |

GE IC697ALG320

Product Introduction

The GE IC697ALG320 is a mid-range 8-channel analog input module in GE’s Series 90-70 PLC family, designed as the “balanced solution for medium-scale data acquisition”—enabling reliable collection and digitization of multi-type sensor signals (voltage, current, thermocouple) from industrial field devices (e.g., temperature transmitters, pressure transducers, level sensors). Distinguished from the low-channel IC697ALG220 (4-channel) and high-precision IC697ALG440 (16-channel, ±0.1% FS), the IC697ALG320 emphasizes “cost-performance balance”: it packs 8 independent channels into a single chassis slot, maintains industry-standard 16-bit resolution, and supports core thermocouple types—making it ideal for medium-complexity process control scenarios such as small chemical reactors, regional water treatment stations, and packaging production lines where 8–16 analog input points are required without excessive precision overhead.

Positioned for small-to-mid industrial systems requiring moderate analog data collection, the IC697ALG320 inherits Series 90-70’s rugged design while optimizing power consumption: 2500V AC channel-to-backplane isolation blocks interference from nearby motor drives, and 220mA max power draw fits entry-level chassis power budgets. It pairs seamlessly with versatile Series 90-70 components—controlled by IC697CPU770 (mid-range CPU) and powered by IC697PWR701 (5A power supply)—serving as the “analog signal bridge” in balanced automation architectures. For systems needing 8 analog input points, it reduces chassis slot usage by 50% compared to 4-channel modules and cuts hardware costs by 40% versus 16-channel high-precision modules.

Core Advantages and Technical Highlights

8-Channel Balanced Density for Medium-Scale Systems: The module’s 1-slot 8-channel design avoids over-provisioning in mid-sized applications. A regional water treatment station uses one IC697ALG320 to monitor 4 pressure points (4-20mA) and 4 pH values (0-10V)—fitting in a 4-slot IC697CHS710 chassis alongside CPU and communication modules, reducing cabinet space by 30% versus using two 4-channel modules.

16-Bit Precision at Mid-Range Cost: 16-bit resolution and ±0.25% FS accuracy meet most industrial monitoring needs without premium pricing. A packaging line uses the module to measure 8 conveyor speed signals (0-5V)—detecting 0.01 m/s increments that basic 12-bit modules miss, reducing packaging errors by 25% while costing 35% less than IC697ALG440.

Multi-Signal Adaptability for Diverse Sensors: Support for voltage, current, and 4 thermocouple types eliminates module replacement during sensor upgrades. A small bakery reconfigures 2 channels for J-type thermocouples (oven temperature) and 6 channels for 4-20mA (dough mixer load)—no hardware changes needed when adjusting production processes, cutting reconfiguration time by 70%.

Industrial-Grade Protection for Stable Operation: 2000V AC channel isolation and ±20kV ESD protection resist harsh factory environments. In a plastic injection molding shop, the module maintains stable temperature data collection (via K-type thermocouples) despite 200V AC noise from molding machines—signal error rate <0.01%, avoiding false “overheat” alerts that halt production.

Typical Application Scenarios

In small chemical reactor control, the GE IC697ALG320 (installed in IC697CHS730 8-slot chassis) connects to IC697CPU770 CPU. 8 channels monitor 4 reactor temperatures (J-type thermocouples) and 4 pressure points (4-20mA)—data is relayed via IC697CMM742 communication module to a local SCADA. Auto-calibration ensures ±1°C temperature accuracy, enabling precise control of reaction times and improving product consistency by 18%.

For regional water treatment monitoring, the module pairs with IC697CPM915 CPU. 6 channels collect 4-20mA flow signals from water pumps, and 2 channels measure turbidity (0-10V) from sediment tanks. Isolation protection resists interference from pump motors, and grouped channel wiring simplifies connection to a junction box—data transmission error rate <0.001% meets local environmental monitoring requirements.

In packaging production line monitoring, the GE IC697ALG320 (in IC697CHS710 chassis) monitors 8 packaging machine parameters: 3 temperature signals (K-type thermocouples), 3 pressure signals (4-20mA), and 2 speed signals (0-5V). 80 samples/s sampling rate captures rapid parameter fluctuations—data is fed to the CPU to adjust machine settings, reducing packaging defects by 22% and increasing line efficiency by 15%.

GE IC697ALG320

Related Model Recommendations

IC697CPU770: Mid-range CPU—processes 8-channel analog data in real time (balances performance and cost).

IC697PWR701: 5A power supply—sufficient for module + 3–4 I/O peripherals (fits small chassis).

IC697CHS710: 4-slot mini chassis—ideal for machine-side installation (CPU + module + 2 I/O).

IC697SVR140: Signal conditioner—boosts long-distance (≤500m) thermocouple signal integrity.

IC697CMM742: Multi-channel communication module—forwards analog data to SCADA/MES (via Modbus TCP).

IC697MDL760: 4-channel analog output module—executes control commands based on IC697ALG320 data (e.g., valve adjustment).

IC697TERM100: Terminal block extension—simplifies wiring for 8-channel sensor connections (reduces clutter).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Power off the chassis (e.g., IC697CHS710) and verify CPU compatibility (IC697CPM915 recommended for small systems). Required tools: anti-static wristband, torque screwdriver (0.8–1.2 N·m), wire strippers (24–18 AWG), multimeter, and calibration signal generator. Clean slot contacts with lint-free cloth dampened with isopropyl alcohol.

Installation and wiring: Align the module with chassis rails, push until latched, and secure with screws. Wire sensors to terminal block (group 1-2): connect signal (+), signal (-), and shield (single-point grounding). For thermocouples: use twisted-pair shielded wire (≤30m) and avoid routing near AC power lines. Ensure channel wiring matches configured signal type (e.g., thermocouple polarity).

Commissioning steps:

Power on the chassis and launch Proficy Machine Edition.

Configure channel groups: assign signal type (voltage/current/thermocouple) and range per group.

Run auto-calibration: use built-in function or external 4-20mA/±10V reference signal.

Verify data accuracy: inject known signal (e.g., 12mA = 50% FS) and confirm module reads ±0.25% error.

Maintenance guidelines: Daily check LEDs (green Power = normal; red Group Fault = channel error). Every 12 months: perform auto-calibration; test isolation resistance (≥80 MΩ @ 500 V DC) with insulation meter. Every 18 months: inspect terminal block screws (tighten if loose from vibration); check shield grounding (ensure <1Ω resistance). Replace if fault LED persists (after rechecking wiring/calibration) or accuracy exceeds ±1% FS.

Service and Guarantee Commitment

The GE IC697ALG320 includes a 1-year manufacturer’s warranty (consistent with mid-range Series 90-70 modules) covering material defects (signal converters, isolation circuits) and workmanship. GE provides technical support via phone/email (9:00–18:00 weekdays), with specialists in analog signal calibration to assist with channel configuration and accuracy troubleshooting.

Beyond warranty, GE offers module repair at regional service centers and stocks essential spare parts (terminal blocks, signal processing chips) with 3–4 business days delivery. Each module undergoes 100% factory testing—including 200-hour accuracy verification, temperature cycling (-10°C to 70°C), and ESD/surge immunity testing—to meet IEC 61131-2 standards for medium-scale industrial measurement applications.