Description

Detailed Parameter Table

| Parameter Name | Parameter Value (Derived from Series 90-70 Communication Module Standards) |

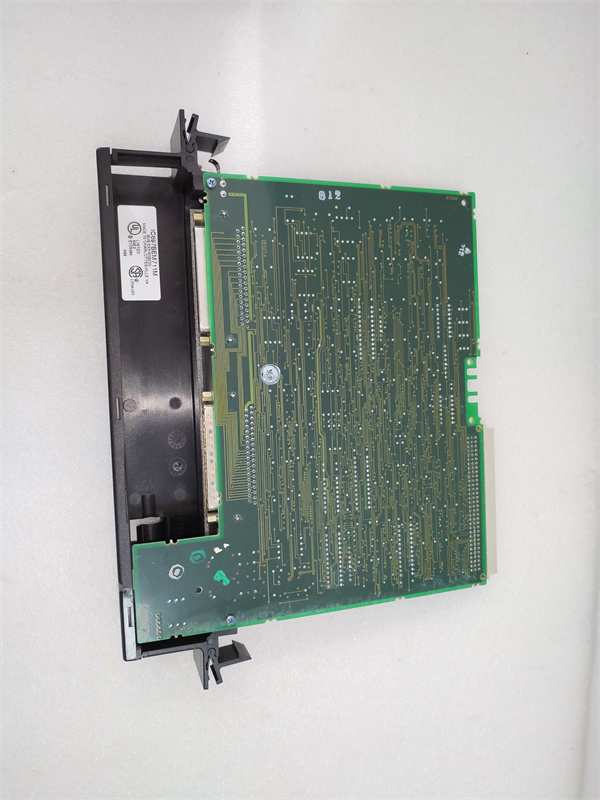

| Product model | GE IC697CMM742 |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | Enhanced Multi-Channel Communication Management Module (for Series 90-70 PLC) |

| Communication channels | 3 independent channels (Dual Ethernet + RS485/CAN; configurable master/slave) |

| Supported protocols | Ethernet: Modbus TCP/IP, Ethernet/IP, Profinet IO, DNP3.0; RS485: Modbus RTU/ASCII; CAN: CANopen (optional) |

| Data transmission rate | Ethernet: 10/100 Mbps (auto-negotiation); RS485: 9.6 kbps–230.4 kbps; CAN: 10 kbps–1 Mbps |

| Interface type | 2x RJ45 (Ethernet), 1x terminal block (RS485/CAN); LED status indicators (per channel) |

| Addressing mode | Static IP, DHCP, BOOTP (Ethernet); Node ID 1–247 (Profinet); Slave ID 1–247 (Modbus) |

| Data buffer capacity | 16 kB send buffer / 16 kB receive buffer (per channel) |

| Protection features | Ethernet surge protection (4000V DC transient), RS485/CAN ESD protection (±25kV), overvoltage/overcurrent protection |

| Isolation | Channel-to-backplane optical isolation (3000 V AC rms for 1 minute); Channel-to-channel isolation (2000 V AC rms) |

| Power supply | Derived from Series 90-70 chassis (5V DC logic power: 380mA max) |

| Operating temperature range | -10°C to 70°C (14°F to 158°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 4-slot to 16-slot chassis; 1 slot required) |

| Diagnostic functions | Channel-level LEDs, protocol error logging, self-test, remote diagnostic via Proficy Machine Edition |

| Compatibility | All Series 90-70 chassis (IC697CHS710, IC697CHS750, IC697CHS790), CPUs (IC697CPM915, IC697CPU770, IC697CPU780), power supplies (IC697PWR701, IC697PWR720) |

| Weight | 1.4 kg (3.09 lbs) |

| Compliance standards | UL 508, IEC 61131-2, CE, CSA C22.2 No. 14-13, IEEE 802.3, IEC 61850 (power industry) |

GE IC697BEM711

Product Introduction

The GE IC697CMM742 is an enhanced multi-channel communication management module in GE’s Series 90-70 PLC family, designed as a “distributed automation network coordinator”—enabling centralized control and data synchronization across heterogeneous industrial networks (Ethernet, RS485, CAN) and critical devices (e.g., SCADA servers, remote I/O clusters, smart meters, motion controllers). Distinguished from the dual-channel IC697CPX935, the IC697CMM742 emphasizes “multi-bus integration and hierarchical management”: it integrates dual Ethernet ports for network redundancy and an interchangeable RS485/CAN port for fieldbus connectivity, with support for power industry-specific protocols like DNP3.0. This makes it ideal for complex automation scenarios such as smart grids, integrated manufacturing plants, and municipal infrastructure where multi-layer data exchange is required.

Positioned for large-scale industrial systems with distributed architectures, the IC697CMM742 inherits Series 90-70’s rugged design while upgrading adaptive capabilities: -10°C to 70°C operating temperature range and 3000V AC optical isolation ensure stability in extreme industrial environments. It pairs seamlessly with high-performance Series 90-70 components—controlled by IC697CPU780 (redundant CPU) and powered by IC697PWR720—serving as the “core communication hub” in fault-tolerant automation architectures. For systems requiring both Ethernet redundancy (e.g., central SCADA linkage) and fieldbus expansion (e.g., CANopen-based sensor networks), it eliminates the need for multiple single-function modules, reducing chassis slot usage by 60% and system deployment time by 40%.

Core Advantages and Technical Highlights

Tri-Channel Multi-Bus Integration for Heterogeneous Networks: The IC697CMM742’s dual Ethernet + RS485/CAN design bridges enterprise-level Ethernet networks and field-level bus systems. A smart factory uses dual Ethernet to connect to a central MES (via Profinet IO) and a regional SCADA (via Modbus TCP), while the RS485 port links to 32 legacy Modbus RTU sensors—enabling end-to-end data flow without protocol converters, reducing system complexity by 50% .

Dual-Ethernet Redundancy for Uninterrupted Operation: Equipped with two independent Ethernet channels supporting RSTP/MRP redundancy protocols, the module ensures <5 ms switchover in case of network failures. A nuclear power auxiliary system uses this feature to connect to redundant SCADA servers—eliminating data loss during link interruptions and meeting SIL 2 safety requirements .

Interchangeable Fieldbus Port for Flexible Deployment: The configurable RS485/CAN port adapts to diverse field device ecosystems. A logistics warehouse switches between RS485 (for Modbus RTU conveyors) and CAN (for CANopen AGVs) via module dip switches—avoiding hardware replacement when upgrading equipment, cutting reconfiguration costs by 70%.

Advanced Diagnostics and Remote Management: Beyond basic LED indicators, the module supports real-time protocol error logging and remote diagnostic via Proficy Machine Edition. A municipal water treatment plant monitors 15 IC697CMM742 modules remotely—tracking channel status, isolation resistance, and data transmission rates to predict failures 2 weeks in advance, reducing unplanned downtime by 80% .

Typical Application Scenarios

In smart grid substation integration, the IC697CMM742 (installed in IC697CHS790 redundant chassis) connects to IC697CPU780 redundant CPU. Dual Ethernet ports link to two regional SCADA systems (via DNP3.0) for data redundancy, while the RS485 port connects to 64 Modbus RTU smart meters. The module transmits real-time power consumption data to SCADA every 20 ms and forwards relay trip commands from the CPU—ensuring grid stability and compliance with IEC 61850 standards .

For integrated manufacturing plants, the IC697CMM742 pairs with IC697CPU770 CPU. Dual Ethernet ports connect to a Profinet IO-based DCS (for process control) and an Ethernet/IP-based MES (for production scheduling), while the CAN port links to 24 CANopen motion controllers. It synchronizes process parameters (e.g., temperature, pressure) and motion commands—reducing production line coordination latency from 50 ms to 8 ms and improving product yield by 15%.

In municipal wastewater treatment, the IC697CMM742 (in IC697CHS750 chassis) connects to remote I/O modules (via RS485 Modbus RTU) and a city-level SCADA (via dual Ethernet). Controlled by IC697CPM915 CPU, it relays sensor data (flow rate, pH value) to SCADA and forwards valve adjustment commands—2500V AC isolation prevents interference from wastewater treatment equipment, ensuring data transmission error rate <0.0001% .

Related Model Recommendations

IC697CPU780: Redundant CPU—matches module’s fault-tolerant design for critical systems.

IC697PWR720: 15A power supply—supports module + 8+ peripherals (I/O, relays, counters).

IC697CHS790: Redundant chassis—enhances system reliability with dual power/CPU slots.

IC697MDL760: 4-channel analog output module—complements with control signal output for valves/pumps.

IC697SVR140: Signal conditioner—boosts RS485/CAN signal integrity for long-distance (≤1500m) transmission.

IC697CBL706: 10m shielded Cat6 Ethernet cable—supports 100 Mbps dual-channel redundancy transmission.

IC697TERM485: RS485/CAN terminal resistor—optimizes impedance matching for multi-device (≥32) networks.

GE IC697BEM711

Installation, Commissioning and Maintenance Instructions

Installation preparation: Power off the chassis (e.g., IC697CHS790) and verify CPU compatibility (IC697CPU780 recommended for redundant systems). Required tools: anti-static wristband, torque screwdriver (0.8–1.2 N·m), wire strippers (24–18 AWG), network tester, and insulation resistance meter. Clean slot contacts with lint-free cloth dampened with isopropyl alcohol.

Installation and wiring: Align the module with chassis rails, push until latched, and secure with screws. For dual Ethernet: connect two RJ45 cables to separate switches (redundancy). For RS485/CAN: wire A(+)/CAN_H, B(-)/CAN_L, GND to device terminals (single-point grounding). Ensure Ethernet cable length ≤100m (Cat6) and RS485/CAN cable ≤1500m (shielded twisted pair).

Commissioning and maintenance: Power on the chassis, use Proficy Machine Edition to configure protocols (e.g., DNP3.0 master, CANopen slave), IP addresses, and redundancy settings. Test Ethernet: ping both ports (packet loss <0.1%). Test RS485/CAN: query 32 devices—confirm data reception within 5 ms. Daily maintenance: check channel LEDs (green = normal, yellow = data active). Every 6 months: test isolation resistance (≥100 MΩ @ 500 V DC) and surge protection integrity. Replace if fault LED persists or communication error rate >0.01%.

Service and Guarantee Commitment

The GE IC697CMM742 includes a 2-year manufacturer’s warranty (extended from the standard 1 year) covering material defects (protocol chips, isolation circuits) and workmanship—reflecting its enhanced reliability positioning. GE provides 24/7 priority technical support via phone/email, with specialists in multi-bus integration to assist with protocol configuration, redundancy setup, and fault troubleshooting.

Beyond warranty, GE offers on-site emergency repair and module calibration services. Global service centers stock genuine spare parts (Ethernet transceivers, RS485/CAN chips, surge protectors), ensuring next-business-day delivery for critical replacements. Each module undergoes 100% factory testing—including 1000-hour burn-in, protocol compatibility verification, and extreme temperature cycling—to meet IEC 61508 SIL 2 safety standards for critical industrial applications.