Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IC697BEM733 |

| Manufacturer | GE (General Electric) Industrial Solutions |

| Product category | Series 90-70 PLC Standard Backplane Expansion Module |

| Expansion function | Extends Series 90-70 main rack to remote racks; supports daisy-chain topology |

| Maximum remote racks supported | Up to 3 remote racks per main rack (with compatible expansion modules) |

| Backplane communication rate | 1 Mbps (differential signaling; compatible with Series 90-70 backplane protocols) |

| Maximum expansion distance | Up to 50 meters (164 feet) with standard GE differential expansion cables |

| Compatibility | All Series 90-70 CPUs (IC697CPU771, IC697CPU750); works with Series 90-70 5/10/15-slot racks (e.g., IC697RACK10) |

| Physical dimensions | 101.6 mm (W) × 165.1 mm (H) × 190.5 mm (D) (fits Series 90-70 rack slots) |

| Power consumption | 5 V DC, 0.9 A (powered via Series 90-70 main/remote rack backplane) |

| Environmental operating temp | 0°C to 60°C (32°F to 140°F) |

| Environmental storage temp | -40°C to 85°C (-40°F to 185°F) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

| Vibration resistance | 5 g peak (10 Hz to 2000 Hz) per IEC 60068-2-6 |

| Shock resistance | 30 g peak (11 ms duration) per IEC 60068-2-27 |

| Compliance standards | UL 508, CSA C22.2 No. 14, IEC 61131-2, CE marked |

| Diagnostic features | LED indicators (power, backplane communication, expansion link status, fault); basic error checking (parity verification) |

GE IC697BEM733

Product Introduction

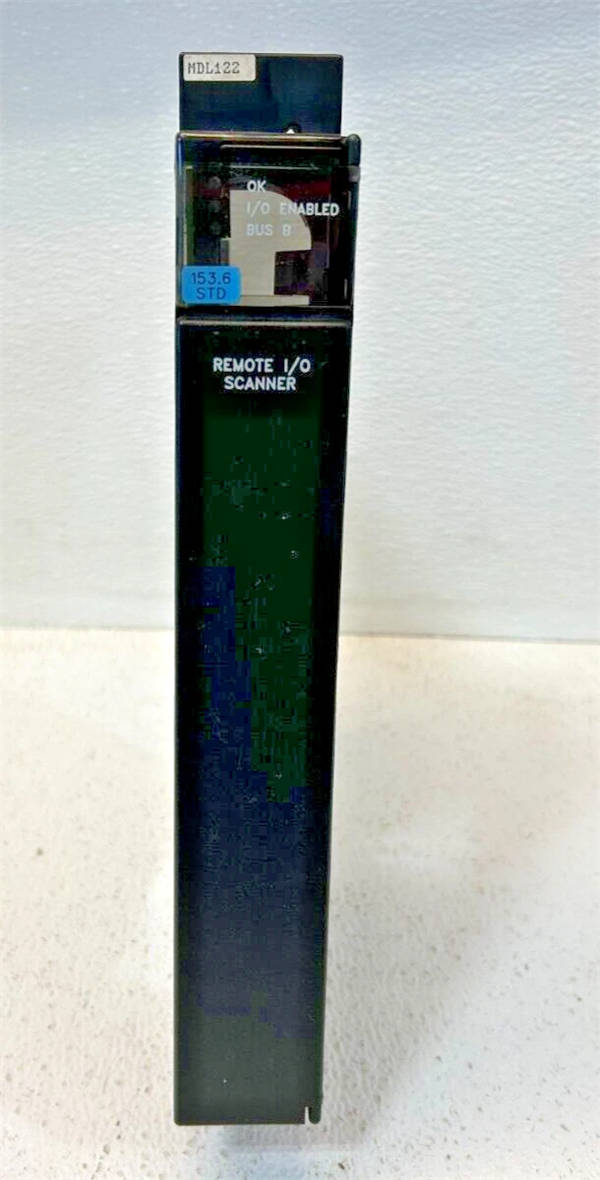

The GE IC697BEM733 is a reliable standard backplane expansion module designed exclusively for GE’s Series 90-70 PLC platform, engineered to solve the challenge of distributed I/O and control in medium-scale industrial facilities. As a predecessor to the high-performance GE IC697BEM733G, it retains the core function of bridging Series 90-70 main racks (equipped with CPUs like the IC697CPU771) and remote racks, enabling seamless transmission of I/O signals, control commands, and diagnostic data across the system.

Unlike entry-level expansion modules with limited range, the GE IC697BEM733 supports expansion distances up to 50 meters and up to 3 remote racks via daisy-chain topology—ideal for applications like manufacturing cells, small-scale water treatment plants, or regional power distribution cabinets where equipment is spread but not in extreme environments. Its plug-and-play compatibility with Series 90-70 racks and CPUs eliminates complex integration, while its 1 Mbps communication rate ensures sufficient speed for non-time-critical processes. For users prioritizing cost-effectiveness without sacrificing reliability, the GE IC697BEM733 delivers a balanced solution for extending control system reach.

Core Advantages and Technical Highlights

Cost-effective distributed control: The GE IC697BEM733 is optimized for budget-conscious applications, offering essential expansion functionality at a lower price point than the upgraded GE IC697BEM733G. It eliminates the need to purchase a second CPU for remote equipment, instead leveraging the main rack’s CPU (e.g., IC697CPU771) to manage up to 3 remote racks—reducing system costs by up to 40% compared to dual-CPU setups. For example, a small automotive component factory can use the GE IC697BEM733 to connect 2 remote racks (housing I/O for assembly stations) to a central main rack, avoiding the expense of additional controllers.

Simplified daisy-chain topology: The GE IC697BEM733 supports daisy-chain wiring between main and remote racks, meaning only one cable is needed to connect sequential remote racks (e.g., main rack → remote rack 1 → remote rack 2). This reduces cable complexity and material costs compared to star-topology modules, which require a separate cable from the main rack to each remote unit. For facilities with linear layouts (e.g., a conveyor line with evenly spaced sensors), this design simplifies installation and troubleshooting—maintenance teams can easily trace signal paths along the daisy chain.

Reliable error detection and status monitoring: Equipped with parity verification for data transmission, the GE IC697BEM733 detects corrupted data and triggers a fault alert via its red LED indicator—preventing incorrect control decisions caused by signal errors. Its intuitive LED array (green for power, blue for backplane communication, amber for link activity) provides real-time status at a glance, eliminating the need for specialized tools to diagnose basic issues (e.g., a disconnected cable or power loss to a remote rack). This accessibility reduces troubleshooting time, making it suitable for teams with limited advanced technical training.

Broad Series 90-70 ecosystem compatibility: The GE IC697BEM733 is fully compatible with all Series 90-70 CPUs (from the mid-range IC697CPU750 to the IC697CPU771) and 5/10/15-slot racks (e.g., IC697RACK10). It integrates seamlessly with existing Series 90-70 I/O modules (such as the IC697MDL240 digital input module) and power supplies (e.g., IC697PWR711), allowing users to expand legacy systems without replacing existing components. This backward compatibility protects prior investments and extends the lifecycle of Series 90-70 installations.

Typical Application Scenarios

Medium-scale manufacturing cells: In a small electronics assembly plant with 3 production cells (each with soldering stations, test equipment, and conveyor belts), the GE IC697BEM733 connects a central main rack (with IC697CPU771) to 3 remote racks (one per cell). Each remote rack houses IC697MDL240 digital input modules (for sensor data) and IC697MDL340 digital output modules (for controlling conveyors). The GE IC697BEM733 transmits data between the main CPU and remote racks at 1 Mbps—fast enough for assembly line timing (where cycles are 1-2 seconds) —and its daisy-chain design simplifies wiring along the linear layout of the cells. If a sensor fails, the module’s fault LED alerts operators, minimizing production downtime.

Municipal water treatment plants (small facilities): For a water treatment plant serving a small town (treating 500,000 gallons per day), the GE IC697BEM733 expands the control system to 2 remote racks: one near the intake pumps and one at the filtration unit. The main rack (with IC697CPU750) uses the GE IC697BEM733 to receive analog data (e.g., flow rates via 4-20 mA signals from the IC697MDL655 module) and send control commands (e.g., adjusting pump speed). The module’s 50-meter range covers the distance between the main control room and the farthest remote rack, while its reliability ensures consistent operation—critical for meeting drinking water quality standards.

Regional power distribution cabinets: In a suburban power distribution network with 3 local cabinets (each monitoring transformers and switchgear), the GE IC697BEM733 connects a central main rack (at a utility substation) to the remote cabinets. Each remote rack uses IC697MDL655 analog input modules to measure voltage and current, with data transmitted to the main CPU via the GE IC697BEM733. The module’s 1 Mbps rate is sufficient for the 5-second data sampling interval required for load monitoring, and its compliance with UL 508 standards ensures safety in electrical environments. If a transformer exceeds load limits, the main CPU receives the alert via the module and triggers a protective relay.

GE IC697BEM733

Related Model Recommendations

GE IC697BEM733G: High-performance upgrade of the GE IC697BEM733. Offers faster speed (2 Mbps vs. 1 Mbps), longer distance (100m vs. 50m), and ATEX certification—ideal for upgrading to harsh/hazardous environment use.

GE IC697CPU771: Mid-range Series 90-70 CPU module, optimized for use with GE IC697BEM733. Provides sufficient processing power to manage 3 remote racks and associated I/O.

GE IC697RACK10: 10-slot Series 90-70 rack, compatible with GE IC697BEM733. Used as remote racks to house I/O modules, with the expansion module enabling communication to the main rack.

GE IC697PWR711: Standard power supply module for Series 90-70 racks, powers the GE IC697BEM733 via the backplane. Delivers stable 5 V DC to support the module’s 0.9 A power needs.

GE IC697MDL240: 32-channel digital input module, paired with GE IC697BEM733. Installed in remote racks to collect sensor data (e.g., limit switch status), which is transmitted to the main CPU.

GE IC697MDL340: 32-channel digital output module, complementary to GE IC697BEM733. Sends control signals from the main CPU to remote devices (e.g., conveyor motors, valves).

GE IC697CSE784C: 100 Mbps Ethernet module for Series 90-70, works with GE IC697BEM733. Transmits data from the expanded I/O system to SCADA systems for remote monitoring.

GE IC697MSC801: 8 MB memory module for Series 90-70, used with GE IC697BEM733. Stores historical data from remote racks (e.g., production counts, sensor trends) for reporting.

GE IC697BEM741: Entry-level backplane expansion module, a more basic alternative to GE IC697BEM733. Supports only 2 remote racks and 30-meter distance—suitable for ultra-small systems.

GE IC697MDL655: 8-channel analog input module, installed in remote racks connected via GE IC697BEM733. Collects process data (e.g., temperature, pressure) for the main CPU to analyze and control.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697BEM733, power off the Series 90-70 main and remote racks and wear an anti-static wristband to protect internal components. Ensure the main rack (e.g., IC697RACK10) has an available slot (slots 2-20, as slot 1 is reserved for the CPU) and is powered by a compatible supply (e.g., GE IC697PWR711) to support the module’s 0.9 A consumption. Gather tools: a screwdriver (to secure the module), torque wrench (4.5 N·m for rack screws), GE-approved differential expansion cables (length matching the 50-meter max distance), and a PC with Proficy Machine Edition (v8.0+). Verify the environment: 0°C to 60°C, 5%-95% humidity (non-condensing), and no exposure to excessive dust or liquids.

Commissioning steps:

Install GE IC697BEM733 in the main rack: align the module with the slot, slide it into place until the backplane connector seats, and secure with screws (torque to 4.5 N·m). Install identical GE IC697BEM733 modules in each remote rack.

Connect racks via daisy-chain: Run a differential cable from the main rack module’s “OUT” port to the first remote rack module’s “IN” port. Then connect the first remote’s “OUT” port to the second remote’s “IN” port, and so on (up to 3 remotes).

Power on the main rack first, then remote racks. Confirm LEDs: green (power), blue (backplane communication with CPU), amber (link activity) — no red fault LEDs should be lit.

Launch Proficy Machine Edition, connect to the CPU (e.g., IC697CPU771), and use “Module Discovery” to detect the GE IC697BEM733. Configure the module: set the number of remote racks and map remote I/O addresses to the CPU’s memory.

Test functionality: Activate a sensor connected to a remote IC697MDL240 module and verify the CPU receives the signal within 10 ms. Disconnect one remote rack to confirm the remaining remotes stay connected (daisy-chain redundancy).

Maintenance suggestions:

Daily: Inspect LEDs—green power, blue backplane, and amber link activity indicate normal operation. A red fault LED signals issues (e.g., cable damage, parity error) that require immediate checks.

Weekly: Clean the module’s backplane connector and cable ports with a dry, lint-free cloth to remove dust (prevents intermittent communication). Check differential cables for wear (e.g., frayed insulation) and replace if damaged.

Monthly: Use Proficy Machine Edition to run a basic diagnostic scan—verify data transmission between main and remote racks and check for parity errors. Ensure the main rack power supply delivers stable 5 V DC (voltage fluctuations can cause link drops).

Quarterly: Test the module’s vibration resistance by visually inspecting connections after plant maintenance (e.g., nearby equipment repairs that may cause shocks). Verify the operating environment remains within 0°C to 60°C using a temperature logger.

Annually: Back up the GE IC697BEM733 configuration (via Proficy Machine Edition) to an encrypted external drive. Replace differential cables older than 5 years to prevent signal degradation—aged cables increase the risk of data errors.

Service and Guarantee Commitment

The GE IC697BEM733 is backed by a 2-year standard manufacturer’s warranty from GE Industrial Solutions, covering defects in materials, workmanship, and performance (e.g., communication rate below 1 Mbps, link failure within 50 meters) under normal industrial use. During the warranty period, if the module fails to meet published specifications, GE will repair or replace it free of charge, including return shipping for qualifying claims.

Beyond warranty, GE offers dedicated support for the GE IC697BEM733:

24/7 technical assistance: Certified engineers with expertise in Series 90-70 expansion modules are available via phone/email to help with installation troubleshooting, daisy-chain configuration, and fault diagnosis—critical for minimizing downtime in active production.

Online resources: Access user manuals, wiring diagrams, and firmware updates on GE’s industrial support portal—tailored to the GE IC697BEM733’s integration with Series 90-70 CPUs (e.g., IC697CPU771).

Extended service contracts: For users with critical operations (e.g., water treatment plants), customizable contracts include annual on-site inspections, priority technical support (2-hour response time), and expedited replacement—ensuring the module’s long-term reliability.

GE’s global network of regional warehouses stocks replacement GE IC697BEM733 modules, enabling fast delivery (typically 48 hours) for urgent replacements. With decades of experience in industrial automation, GE stands behind the GE IC697BEM733 as a cost-effective, reliable solution for extending Series 90-70 control systems.