Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

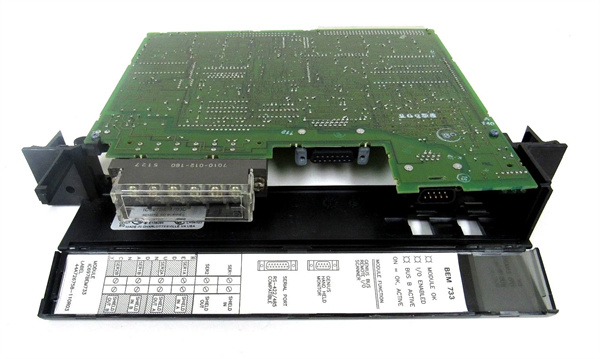

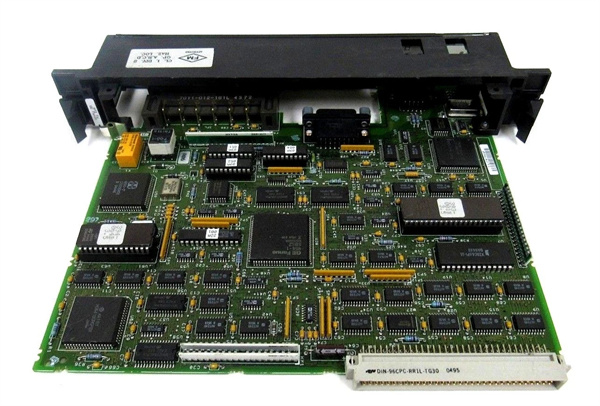

| Product model | IC697BEM733D |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | Industrial Ethernet Communication Module (for Series 90-70 PLC Systems) |

| Communication protocols | PROFINET RT, EtherNet/IP (CIP), Modbus TCP/IP, GE SRTP (Serial Real-Time Protocol) |

| Ethernet ports | 2 x 10/100/1000 Mbps RJ-45 ports (supports auto-negotiation, full/half-duplex) |

| Maximum network nodes | Up to 256 devices per port (supports daisy-chain and star topologies) |

| Power supply | Derived from Series 90-70 chassis (5V DC, 300mA max power consumption) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 5-slot to 16-slot chassis) |

| Diagnostic functions | Port link/activity LEDs, module health LED, fault logging (via PLC software) |

| Redundancy support | Yes (dual-port redundancy for network failover; supports RSTP/STP protocols) |

| Compatibility | All Series 90-70 PLC CPUs (e.g., IC697CPU780, IC697CPU770) |

GE IC697BEM733D

Product Introduction

The GE IC697BEM733D is a flagship Ethernet communication module in GE’s Series 90-70 PLC lineup, engineered to serve as the critical “network gateway” for large-scale industrial automation systems. Unlike basic communication modules, the GE IC697BEM733D integrates multi-protocol support and gigabit Ethernet ports, enabling seamless data transfer between Series 90-70 controllers and upstream devices (e.g., SCADA systems, HMIs, MES platforms) or downstream components (e.g., remote I/O, servo drives).

Technical positioning for high-demand applications (e.g., power generation, heavy manufacturing), the GE IC697BEM733D eliminates communication bottlenecks common in legacy modules. It supports dual-port redundancy, ensuring network continuity if one port fails—critical for processes where unplanned downtime is costly. In automation architectures, the GE IC697BEM733D acts as a “data router,” translating protocols (e.g., PROFINET to Modbus TCP/IP) and synchronizing real-time control data, making it indispensable for integrated, plant-wide automation.

Core Advantages and Technical Highlights

Multi-protocol versatility: The GE IC697BEM733D natively supports four industrial protocols (PROFINET RT, EtherNet/IP, Modbus TCP/IP, GE SRTP), eliminating the need for external protocol converters. For example, in an automotive factory, it can connect a Series 90-70 PLC (using SRTP) to PROFINET-based robotic arms and EtherNet/IP-enabled HMIs—all via a single GE IC697BEM733D. This reduces hardware costs and simplifies network management.

Gigabit speed and redundancy: Equipped with 10/100/1000 Mbps ports, the GE IC697BEM733D delivers data transfer rates up to 10x faster than 100 Mbps modules, ideal for high-volume data applications (e.g., real-time video monitoring of production lines). Its dual-port design supports RSTP/STP protocols, enabling automatic failover (≤50 ms) if a network link is disrupted—ensuring uninterrupted communication in critical systems like power plant turbine control.

Seamless Series 90-70 integration: Optimized for Series 90-70 chassis, the GE IC697BEM733D leverages the platform’s high-speed backplane (up to 160 Mbps) for low-latency data exchange with the PLC CPU. It draws power directly from the chassis, eliminating the need for external power supplies and reducing cable clutter in control cabinets. Configuration is done via GE’s Proficy Machine Edition software, with pre-built templates for common protocols—cutting setup time by 30% compared to generic modules.

Robust industrial design: The GE IC697BEM733D is built to withstand harsh industrial environments, with a wide operating temperature range (0°C-60°C) and resistance to vibration (5 g peak) and shock (30 g peak). It also features EMC compliance (EN 61000-6-2) to shield against electrical noise from nearby motors or variable frequency drives (VFDs)—ensuring stable communication in noisy settings like steel mills.

Typical Application Scenarios

In power generation (e.g., coal-fired plants), the GE IC697BEM733D is central to turbine control systems. It connects a IC697CPU780 PLC to PROFINET-based vibration sensors (monitoring turbine health) and Modbus TCP/IP-enabled SCADA systems (for remote monitoring by plant operators). The module’s gigabit speed ensures real-time transmission of vibration data (critical for predicting equipment failure), while dual-port redundancy prevents communication loss during network maintenance—avoiding costly turbine shutdowns.

For heavy machinery manufacturing (e.g., excavator production), the GE IC697BEM733D links Series 90-70 PLCs to EtherNet/IP-enabled servo drives and HMIs. It synchronizes control signals (e.g., for robotic welding arms) with production data (e.g., weld quality metrics) via SRTP, enabling the PLC to adjust parameters in real time. The module’s multi-protocol support eliminates the need for separate modules for drives and HMIs, reducing control cabinet footprint by 20%.

In oil refineries, the GE IC697BEM733D enables distributed control of distillation columns. It connects local temperature/pressure sensors (via Modbus TCP/IP) to a central Series 90-70 PLC, transmitting data to a SCADA system for process visualization. Its rugged design withstands the refinery’s high-temperature, dusty environment, while short-circuit protection on Ethernet ports prevents damage from accidental wire grounding—ensuring reliable operation in hazardous conditions.

GE IC697BEM733D

Related Model Recommendations

IC697BEM731D: Entry-level Series 90-70 Ethernet module, supports EtherNet/IP and Modbus TCP/IP (no PROFINET) — a cost-effective alternative to GE IC697BEM733D for simple networks.

IC697CPU780: High-performance Series 90-70 CPU, paired with GE IC697BEM733D for large-scale applications (e.g., power plant control) requiring high processing power.

IC697CHS790: 16-slot Series 90-70 chassis, required to mount GE IC697BEM733D and associated I/O modules in complex systems.

IC697PWR710: 120/240V AC to 5V DC power supply module, provides chassis power for GE IC697BEM733D in non-DC-powered industrial settings.

IC697BEM734D: Advanced version of GE IC697BEM733D with 4 Ethernet ports and support for PROFINET IRT (for ultra-low latency applications like robotics).

IC693CMM321-JJ: Series 90-30 Ethernet module, compatible with GE IC697BEM733D for cross-platform communication (e.g., linking Series 90-30 and 90-70 PLCs).

IC200EBI001: VersaMax Ethernet module, works with GE IC697BEM733D to connect VersaMax I/O racks to Series 90-70 systems in distributed automation.

IC670ALG330-KB: VersaMax analog input module, pairs with GE IC697BEM733D to transmit sensor data (e.g., temperature) to Series 90-70 PLCs via Ethernet.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697BEM733D, power off the Series 90-70 chassis and verify the control cabinet meets environmental specs (0°C-60°C, 5%-95% non-condensing humidity). Required tools include a torque screwdriver (0.8-1.2 N·m for chassis screws), Ethernet cable tester (to validate Cat5e/Cat6 cables), and anti-static wristband (to prevent ESD damage). Align the module with the chassis guide rails, push until it latches, and secure with front-panel screws—do not hot-swap the module, as this may disrupt chassis backplane communication. Connect Ethernet cables to the RJ-45 ports (use shielded cables for noisy environments).

Maintenance suggestions: Daily maintenance for GE IC697BEM733D involves checking port LEDs (green = link active, amber = data transfer) and the module health LED (steady green = normal). Every 6 months, use compressed air (≤50 psi) to clean dust from the module’s vents and Ethernet ports, preventing overheating or connection issues. If communication fails, first test the Ethernet cable and switch; if the issue persists, use Proficy Machine Edition to check fault logs (e.g., protocol mismatches). When replacing GE IC697BEM733D, ensure the new module’s firmware matches the Series 90-70 CPU to avoid compatibility errors.

Service and Guarantee Commitment

The GE IC697BEM733D comes with a 1-year manufacturer’s warranty, covering defects in materials and workmanship under normal industrial use. GE provides 24/7 technical support via phone, email, and online portals, with certified engineers specializing in Series 90-70 systems available to assist with module configuration, protocol troubleshooting, and network optimization.

Beyond warranty, GE offers on-site commissioning services for GE IC697BEM733D, including network topology design, protocol testing, and integration verification with existing PLC systems. Global service centers stock genuine spare parts, ensuring fast replacement (typically 1-3 business days for urgent orders) to minimize downtime. GE’s commitment to quality is backed by rigorous factory testing—each GE IC697BEM733D undergoes 100% protocol compatibility and performance validation before shipment, ensuring it meets industrial reliability standards from day one.