Description

Detailed Parameter Table

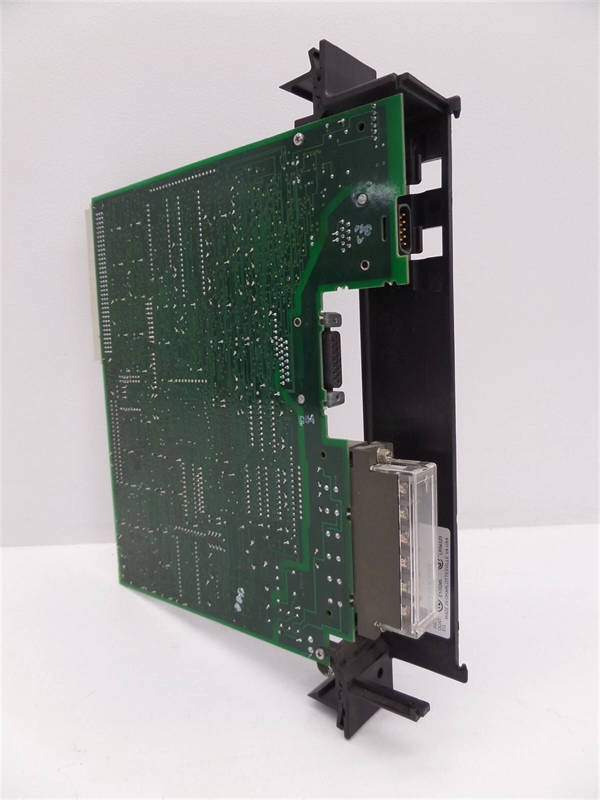

| Parameter Name | Parameter Value |

| Product model | IC697BEM733G |

| Manufacturer | GE (General Electric) Industrial Solutions |

| Product category | Series 90-70 PLC High-Speed Backplane Expansion Module |

| Expansion function | Extends Series 90-70 main rack to remote racks; supports daisy-chain topology |

| Maximum remote racks supported | Up to 4 remote racks per main rack (with compatible expansion modules) |

| Backplane communication rate | 2 Mbps (high-speed differential signaling; 2x faster than IC697BEM741) |

| Maximum expansion distance | Up to 100 meters (328 feet) with standard GE differential expansion cables; up to 500 meters with optional fiber-optic adapters |

| Compatibility | All Series 90-70 CPUs (IC697CPU789, IC697CPU771); works with Series 90-70 5/10/15/20-slot racks (e.g., IC697RACK20) |

| Physical dimensions | 101.6 mm (W) × 165.1 mm (H) × 190.5 mm (D) (fits Series 90-70 rack slots) |

| Power consumption | 5 V DC, 1.1 A (powered via Series 90-70 main/remote rack backplane) |

| Environmental operating temp | -10°C to 65°C (14°F to 149°F) (wider range than IC697BEM741) |

| Environmental storage temp | -40°C to 85°C (-40°F to 185°F) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing); moisture-resistant coating |

| Vibration resistance | 8 g peak (10 Hz to 2000 Hz) per IEC 60068-2-6 (higher tolerance than IC697BEM741) |

| Shock resistance | 40 g peak (11 ms duration) per IEC 60068-2-27 (higher tolerance than IC697BEM741) |

| Compliance standards | UL 508, CSA C22.2 No. 14, IEC 61131-2, CE marked, ATEX Zone 2, IECEx |

| Diagnostic features | LED indicators (power, backplane communication, expansion link status, fault); built-in error checking (CRC); link quality monitoring |

GE IC697BEM733G

Product Introduction

The GE IC697BEM733G is a high-speed backplane expansion module designed exclusively for GE’s Series 90-70 PLC platform, engineered to address the need for long-distance, high-throughput communication between main and remote racks. As an advanced upgrade to the standard IC697BEM741, it doubles the backplane communication rate to 2 Mbps and extends the maximum expansion distance to 100 meters (or 500 meters with fiber optics), making it ideal for large-scale industrial facilities where equipment is widely distributed.

As a critical connectivity component, the GE IC697BEM733G acts as a bridge between the Series 90-70 main rack (equipped with a CPU like the IC697CPU789) and remote racks, enabling seamless data transmission of I/O signals, control commands, and diagnostic data. Its support for up to 4 remote racks and daisy-chain topology simplifies system design, while the wider operating temperature range (-10°C to 65°C) and ATEX certification allow use in harsh and hazardous environments—such as oil refineries, mining operations, and outdoor power substations. Whether used to expand I/O capacity or connect distributed equipment, the GE IC697BEM733G delivers the speed, reliability, and scalability needed for complex Series 90-70 automation systems.

Core Advantages and Technical Highlights

High-speed 2 Mbps backplane communication: The GE IC697BEM733G’s 2 Mbps differential backplane rate is twice as fast as the IC697BEM741’s 1 Mbps, enabling rapid data exchange between main and remote racks. This speed is critical for time-sensitive applications, such as high-speed manufacturing lines or power grid control, where delays in data transmission can cause process errors or safety risks. For example, in an automotive stamping plant with 4 remote racks (each housing 32 I/O points), the GE IC697BEM733G can transmit all I/O data to the IC697CPU789 in under 5 ms—ensuring synchronized control of stamping presses and material handling systems.

Extended distance and fiber-optic compatibility: Unlike the IC697BEM741 (max 30 meters), the GE IC697BEM733G supports expansion distances up to 100 meters with standard differential cables. For even longer distances (up to 500 meters), it works with optional GE fiber-optic adapters—eliminating signal degradation and electromagnetic interference (EMI) common in copper cables. This is a game-changer for facilities like oil refineries, where main control rooms may be hundreds of meters away from process units, or outdoor solar farms, where remote racks are spread across large areas. The fiber-optic option also provides immunity to lightning-induced surges, a key advantage in outdoor applications.

Robust environmental and hazardous area certification: The GE IC697BEM733G operates in a wider temperature range (-10°C to 65°C) than the IC697BEM741 (0°C to 60°C) and features a moisture-resistant coating to protect against humidity-related damage. It is also ATEX Zone 2 and IECEx certified, making it safe for use in areas with flammable gases (e.g., chemical plants, offshore oil platforms). Its vibration resistance (8 g peak) and shock resistance (40 g peak) exceed industry standards, ensuring reliable performance in mining operations (where equipment vibration is intense) or heavy manufacturing (where shock from machinery is common). This durability translates to a mean time between failures (MTBF) of over 300,000 hours—minimizing unplanned downtime.

Advanced diagnostics and fault tolerance: The GE IC697BEM733G includes built-in cyclic redundancy check (CRC) error checking to detect corrupted data, and its LED indicators provide real-time status: green for power, blue for backplane communication, amber for expansion link activity, and red for faults. Unlike basic expansion modules, it also monitors link quality (signal strength, noise level) and logs errors (e.g., CRC failures, link drops) that can be accessed via GE’s Proficy Machine Edition software. For example, if a copper cable is damaged, the module immediately alerts the CPU and logs the fault location—allowing maintenance teams to quickly identify and replace the cable. Its support for daisy-chain topology also provides partial redundancy: if one remote rack fails, the others remain connected to the main rack.

Typical Application Scenarios

Mining operations (underground and surface): In underground coal mines, the GE IC697BEM733G connects the IC697CPU789 (housed in a surface control room) to 4 remote racks located in underground galleries (up to 500 meters away via fiber optics). Each remote rack houses I/O modules for monitoring conveyor speed (4-20 mA), gas levels (±10 V), and emergency stop buttons. The module’s 2 Mbps speed ensures real-time data transmission—critical for triggering immediate shutdowns if gas levels exceed safe limits. Its ATEX certification and moisture-resistant coating protect against methane gas and underground humidity, while its 8 g vibration resistance withstands conveyor-induced vibrations.

Outdoor solar power plants: Solar farms with thousands of panels use the GE IC697BEM733G to connect remote racks (each monitoring 100 solar inverters) to a central IC697CPU789. The module’s fiber-optic compatibility enables expansion distances up to 500 meters, covering large solar fields, and its EMI immunity prevents signal interference from power inverters. The GE IC697BEM733G transmits inverter data (voltage, current, efficiency) to the CPU, which optimizes power output and detects faulty inverters. Its wide temperature range (-10°C to 65°C) handles extreme outdoor conditions—from freezing winters to hot summers—ensuring year-round operation.

Chemical processing plants: In a chemical plant with multiple process units (e.g., mixing, distillation, packaging), the GE IC697BEM733G expands the Series 90-70 system to 4 remote racks (each near a process unit). The module’s ATEX Zone 2 certification allows use in areas with flammable solvent vapors, while its 2 Mbps speed ensures fast transmission of analog data (e.g., reactor temperature, pressure) to the IC697CPU789. If a process unit experiences a fault (e.g., high pressure), the GE IC697BEM733G transmits the alarm to the CPU in under 10 ms—triggering safety valves and preventing equipment damage. Its advanced diagnostics also help identify issues like cable degradation before they cause failures, reducing maintenance costs.

GE IC697BEM733G

Related Model Recommendations

GE IC697BEM741: Standard backplane expansion module for Series 90-70, the predecessor to GE IC697BEM733G. The IC697BEM733G offers faster speed (2 Mbps vs. 1 Mbps) and longer distance (100m vs. 30m); the IC697BEM741 remains suitable for small-scale, short-distance expansions.

GE IC697CPU789: Flagship Series 90-70 CPU module, optimized for use with GE IC697BEM733G. The CPU leverages the module’s high speed to process data from 4 remote racks without performance lag.

GE IC697RACK20: 20-slot Series 90-70 rack, compatible with GE IC697BEM733G. Used as remote racks to house I/O modules, with the module installed in the main rack to connect them to the CPU.

GE IC697PWR712: High-output power supply module for Series 90-70 racks, recommended for systems with GE IC697BEM733G (1.1 A power consumption). Delivers stable 5 V DC to support the module’s high-speed operation.

GE IC697ACC703: Fiber-optic adapter for GE IC697BEM733G. Extends expansion distance from 100 meters to 500 meters, provides EMI immunity, and is ideal for outdoor or long-distance applications.

GE IC697MDL240: 32-channel digital input module, paired with GE IC697BEM733G. Installed in remote racks to collect sensor data, which is transmitted to the CPU via the expansion module.

GE IC697CSE925: Gigabit Ethernet module for Series 90-70, complementary to GE IC697BEM733G. Transmits data from the expanded I/O system to SCADA systems, enabling remote monitoring.

GE IC697MSC802: High-capacity memory module for Series 90-70, used with GE IC697BEM733G. Stores historical data from remote racks (e.g., process trends) for regulatory compliance.

GE IC697CGR935: Multi-protocol gateway module for Series 90-70, works with GE IC697BEM733G to connect remote racks to non-Series 90-70 devices (e.g., Profibus DP sensors).

GE IC697MDL655: 8-channel analog input module, installed in remote racks connected via GE IC697BEM733G. Collects process data (e.g., temperature, pressure) and sends it to the CPU for control.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697BEM733G, power off the Series 90-70 main/remote racks and wear an anti-static wristband. Ensure the main rack (e.g., IC697RACK20) has an available slot (slots 2-20) and is powered by a compatible supply (GE IC697PWR712) to support 1.1 A. Gather tools: screwdriver, torque wrench (4.5 N·m for rack screws), GE-approved differential expansion cables (or fiber-optic cables + adapters), and a PC with Proficy Machine Edition (v9.5+). Verify the environment: -10°C to 65°C, 5%-95% humidity, and compliance with ATEX Zone 2 requirements (if applicable). For fiber-optic installation, ensure cable paths avoid sharp bends (minimum 10 cm radius) to prevent signal loss.

Commissioning steps:

Install GE IC697BEM733G in the main rack: align with the slot, slide into place, and secure with screws (torque to 4.5 N·m). Install compatible expansion modules (e.g., GE IC697BEM733G) in each remote rack.

Connect main and remote racks: use differential cables (up to 100m) or fiber-optic cables + adapters (up to 500m). For daisy-chain topology, connect main rack module → remote rack 1 module → remote rack 2 module, etc.

Power on the main rack first, then remote racks. Confirm LEDs: green (power), blue (backplane communication with IC697CPU789), amber (expansion link activity), no red faults.

Launch Proficy Machine Edition, connect to the CPU, and detect GE IC697BEM733G via “Module Discovery.” Configure the module: set daisy-chain order, enable CRC error checking, and map remote I/O to CPU memory addresses.

Test functionality: trigger a test input (e.g., activate a sensor in remote rack 1) and verify the CPU receives the signal within 5 ms. Test link redundancy by disconnecting one remote rack—ensure others remain connected.

Maintenance suggestions:

Daily: Inspect LEDs—green power, blue backplane, amber link activity indicate normal operation. Red faults signal issues (e.g., cable damage, module failure) requiring immediate attention.

Weekly: Clean module connectors (main and remote) with compressed air (low pressure <50 psi) to remove dust. Check cables for damage (e.g., cuts, bent pins) and replace if necessary.

Monthly: Use Proficy Machine Edition to run link quality tests—verify signal strength (>90% for copper, >85% for fiber) and check for CRC errors. Update module firmware if GE releases critical patches.

Quarterly: For fiber-optic systems, clean fiber connectors with a lint-free cloth and alcohol to remove dirt (prevents signal loss). Test temperature and humidity in module locations to ensure compliance with specs.

Annually: For hazardous areas (ATEX Zone 2), have a third-party inspector verify compliance. Replace aging cables (copper >5 years, fiber >10 years) to prevent signal degradation. Back up module configuration to an encrypted drive.

Service and Guarantee Commitment

The GE IC697BEM733G is backed by a 3-year standard manufacturer’s warranty from GE Industrial Solutions—1 year longer than the IC697BEM741—covering defects in materials, workmanship, and performance (e.g., communication rate <2 Mbps, link failure within distance specs) under normal use. During the warranty period, GE will repair/replace faulty modules free of charge, including expedited shipping for critical applications (e.g., mining, chemical plants).

Beyond warranty, GE offers specialized support:

24/7 technical assistance: Certified engineers with expertise in high-speed expansion modules assist with fiber-optic configuration, fault troubleshooting, and hazardous area compliance—critical for 24/7 operations.

Online resources: Access dedicated manuals, fiber-optic installation guides, and firmware updates on GE’s industrial portal. Webinars cover topics like “Maximizing GE IC697BEM733G Distance” and “ATEX Compliance Best Practices.”

Extended service contracts: Customizable plans include on-site maintenance (quarterly inspections), priority technical support (1-hour response), and expedited replacement (24-hour delivery for global customers). GE stocks replacement modules in 15 regional warehouses to ensure fast access.

GE’s commitment to quality ensures the **GE IC697BEM733