Description

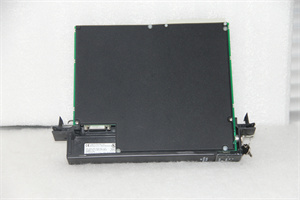

GE Fanuc IC697CPM790 PACSystems RX7i Control Processor for Industrial Automation

The GE Fanuc IC697CPM790 is a high-performance control processor module designed for GE’s PACSystems RX7i platform, delivering real-time automation control in critical industries such as energy, manufacturing, and water treatment. Engineered with a 600 MHz PowerPC processor and 1 GB RAM, this module supports complex logic execution, advanced motion control, and secure industrial networking, ensuring seamless integration in large-scale systems.

1. Product Overview

The IC697CPM790 serves as the brain of PACSystems RX7i, processing I/O data, executing ladder logic, and managing communication with field devices. Its dual Ethernet ports (10/100/1000 Mbps) enable redundant network connections, while SIL 3 compliance (with safety software) makes it ideal for safety-critical applications like oil refineries and power plants. With -40°C to +70°C operating range and hot-swap capability, the module minimizes downtime in harsh environments.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Processor | 600 MHz PowerPC MPC8548 |

| Memory | 1 GB RAM, 4 GB Flash (user-programmable) |

| Communication | Dual Ethernet (Ethernet/IP, Modbus TCP), RS-485 |

| I/O Capacity | Up to 8,192 I/O points (via RX7i chassis) |

| Cycle Time | 0.3 ms for 10k ladder rungs (典型值) |

| Safety Certification | SIL 3 (IEC 61508), PL e (ISO 13849) |

| Power Supply | 24 VDC ±15% (350 mA typical) |

| Dimensions | 254 mm × 140 mm × 64 mm (rack-mount) |

IC697CPM790

3. Key Advantages

- Ultra-Fast Processing: 600 MHz CPU reduces cycle times by 20% compared to legacy models, critical for high-speed manufacturing.

- Redundancy Built-In: Dual-processor configuration (optional) achieves 99.999% availability in power generation.

- Security Features: Built-in firewall and encrypted firmware updates protect against cyber threats in smart factories.

Case Study: A U.S. natural gas processing plant reduced downtime by 30% using IC697CPM790 to control 5,000 I/O points, enabling predictive maintenance for compressors.

4. Applications & Use Cases

- Energy: Manages GE’s LM6000 gas turbines, optimizing fuel efficiency with real-time analytics.

- Manufacturing: Controls robotic assembly lines with sub-millisecond precision, improving throughput by 15%.

- Water Treatment: Dynamically adjusts pump stations using AI algorithms, reducing energy costs by 20%.

Example: A German automotive plant achieved 99.9% uptime for 100+ welding robots using IC697CPM790-based control systems.

5. Competitor Comparison

- Higher Memory: 1 GB RAM vs. 512 MB in comparable modules, supporting complex AI/ML applications.

- Faster Networking: 1 Gbps Ethernet vs. 100 Mbps in legacy models, accelerating OPC UA data exchange.

- Extended Temperature Range: Operates at +70°C vs. +60°C max in some 竞品,suitable for desert deployments.

IC697CPM790

6. Selection Recommendations

- Large-Scale Systems: Choose IC697CPM790 for projects with >2,000 I/O points; smaller systems may use GE’s IC697CPM770.

- Safety-Critical Projects: Pair with GE’s IC697CMM711 safety module for SIL 3 compliance.

- Cost Efficiency: Refurbished units (GE-certified) offer 35% savings with 24-month warranties.

7. Installation & Maintenance Notes

- Networking: Configure dual Ethernet ports for redundancy; use managed switches for QoS.

- Cooling: Ensure airflow of 20 CFM; avoid ambient temperatures >60°C for 24/7 operation.

- Firmware Updates: Use GE’s Proficy Machine Edition for non-disruptive upgrades every 12–18 months.

Shanxi Xinyeda International Trading Co., Ltd. provides genuine and refurbished GE Fanuc IC697CPM790 modules with a 3-year warranty, 24/7 technical support, and global logistics. Visit www.xydcontrol.com for customized automation solutions.