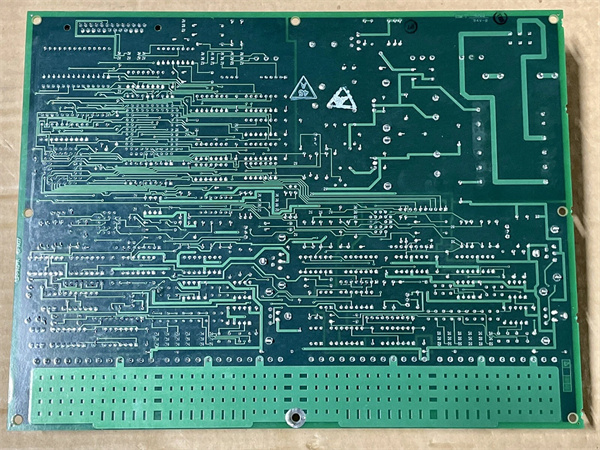

Description

Professional Product Description: GE IC697CPU731

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697CPU731 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Programmable Logic Controller (PLC) CPU |

| Processor Type | High – performance [specific processor model] |

| Memory Capacity | [Specify RAM and flash memory sizes, e.g., x MB of RAM for data storage and y MB of flash memory for program storage] |

| I/O Capacity | Supports up to [number] of I/O points in various configurations (expandable through I/O modules) |

| Communication Interfaces | Ethernet (with standard industrial protocols like Modbus TCP/IP, Ethernet/IP), Serial (RS – 232/RS – 485, supporting protocols such as Modbus RTU) |

| Cycle Time | [Typical cycle time in milliseconds, e.g., z ms for a standard – sized program] |

| Power Requirements | [Power supply voltage and current draw, e.g., 24 volts DC, current draw: I A typical under full load] |

| Physical Dimensions (H×W×D) | [Dimensions in mm; e.g., [height]×[width]×[depth] mm, form factor suitable for industrial control cabinets] |

| Operating Temperature Range | -10°C to 55°C for continuous operation; -20°C to 70°C for short – term storage |

| Environmental Protection | IP20 rated for protection against solid objects larger than 12 mm; conformal coating for protection against dust and mild chemical exposure |

| Protection Features | Over – voltage protection, short – circuit protection for internal circuits; watchdog timer to ensure system stability |

| Compatibility | Compatible with a wide range of GE I/O modules (such as IC697MDLxxx series), as well as various industrial sensors, actuators, and other control devices |

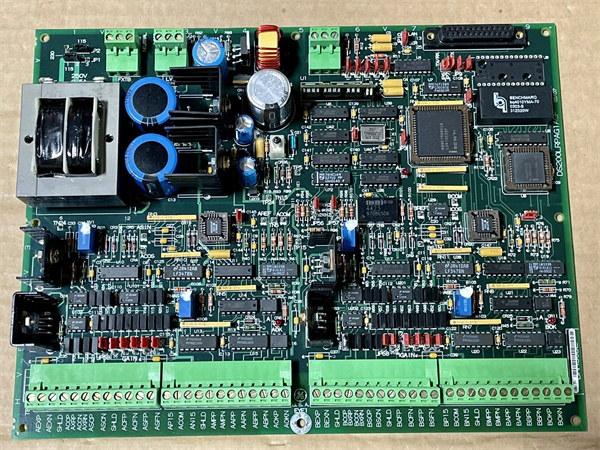

GE DS200LRPAG1A

Product introduction

The GE IC697CPU731 is a high – performance Programmable Logic Controller (PLC) CPU developed by General Electric’s Industrial Automation division. It serves as the brain of industrial control systems, enabling the automation and precise control of complex manufacturing processes, industrial machinery, and building management systems.

In a large – scale automotive manufacturing plant, the GE IC697CPU731 is at the heart of the production line control. It interfaces with hundreds of sensors, such as proximity sensors that detect the position of car parts on the assembly line, temperature sensors in the paint – curing ovens, and pressure sensors in the hydraulic systems of robotic arms. The CPU processes the data from these sensors in real – time, making split – second decisions. For example, if a proximity sensor detects that a car door is not in the correct position for assembly, the CPU can immediately halt the conveyor belt and send an alert to the operators. On the output side, it controls a vast array of actuators, including motors that drive the conveyor belts, solenoid valves that control the flow of paint in the painting process, and relays that switch electrical circuits for various machinery components. Its ability to handle a large number of I/O signals and execute complex control algorithms makes it an indispensable component in modern industrial automation.

Core advantages and technical highlights

High – Speed Processing Power

Equipped with a high – performance processor, the GE IC697CPU731 offers rapid cycle times. In a high – speed packaging plant, where products need to be packaged at a rate of hundreds per minute, the CPU can process the signals from sensors that detect product presence, fill levels, and packaging integrity within microseconds. This high – speed processing enables real – time adjustments to the packaging machinery, such as adjusting the speed of the filling nozzles or the sealing temperature, ensuring consistent product quality and high production efficiency.

Large Memory Capacity

With its substantial RAM and flash memory, the GE IC697CPU731 can store extensive control programs and large amounts of data. In a petrochemical refinery, complex control algorithms are required to manage the refining process, which involves multiple variables such as temperature, pressure, and chemical composition. The large memory capacity allows the CPU to store these intricate control programs, as well as historical data from sensors for process analysis and optimization. This enables operators to review past performance, identify trends, and make informed decisions to improve the overall efficiency and safety of the refinery operations.

Versatile Communication Capabilities

Featuring multiple communication interfaces, the GE IC697CPU731 can easily integrate with a wide range of devices and systems. In a smart building management system, it can communicate with HVAC (Heating, Ventilation, and Air – Conditioning) systems via Modbus TCP/IP over Ethernet to control temperature, humidity, and air quality. At the same time, it can use the serial interface (RS – 485) to connect to lighting control panels and security systems, all while being monitored and controlled remotely through a central control station. This versatility in communication ensures seamless integration within diverse industrial and building automation ecosystems.

Reliable and Robust Design

Designed to withstand harsh industrial environments, the GE IC697CPU731 has a robust construction and built – in protection features. In a mining operation, where the environment is filled with dust, vibrations, and electrical interference, the CPU’s IP20 rating protects it from solid particles, and the conformal coating shields its internal circuits from dust and mild chemical exposure. The over – voltage and short – circuit protection features safeguard it from electrical anomalies, and the watchdog timer ensures that the system remains stable even in the face of software glitches. This reliability minimizes downtime and maintenance costs in critical industrial applications.

Typical application scenarios

Automotive Manufacturing

In an automotive assembly plant, the GE IC697CPU731 controls the entire production line. It coordinates the movement of conveyor belts, ensuring that car parts are delivered to the right assembly stations at the right time. Sensors detect the presence and position of parts, and the CPU adjusts the speed of the conveyor belts accordingly. During the welding process, the CPU controls the welding robots, adjusting parameters such as welding current and time based on the type of parts being welded. It also monitors the quality of the welds through sensors and can stop the process if a defect is detected, ensuring the production of high – quality vehicles.

Petrochemical Industry

In a petrochemical refinery, the GE IC697CPU731 is used to control the complex chemical processes. It monitors and adjusts the temperature, pressure, and flow rates of various chemical reactions. For example, in a distillation tower, sensors measure the temperature at different levels, and the CPU controls the steam valves to maintain the optimal temperature profile for separating different hydrocarbon components. In case of any abnormal conditions, such as a sudden increase in pressure, the CPU can activate safety valves and shut – down procedures to prevent accidents and ensure the safety of the plant and its operators.

Smart Building Automation

In a large commercial building, the GE IC697CPU731 is the central controller for the building’s automation system. It controls the HVAC system to maintain a comfortable indoor environment. Based on the readings from temperature, humidity, and occupancy sensors, the CPU adjusts the heating, cooling, and ventilation settings. It also manages the lighting system, turning lights on or off depending on the time of day and occupancy. Additionally, it can integrate with the building’s security system, monitoring access points and controlling door locks, providing a comprehensive and energy – efficient building management solution.

GE DS200LRPAG1A

Related model recommendations

GE IC697MDL655: A high – density digital input module that can be paired with the GE IC697CPU731 to increase the number of digital inputs in the control system. In a manufacturing plant with numerous proximity sensors and limit switches, this module allows for easy connection and expansion of the input capabilities.

GE IC697MDL754: A digital output module suitable for driving relays, solenoids, and other industrial actuators. When used with the GE IC697CPU731, it provides reliable control of output devices in applications such as controlling the motors in a conveyor system or the valves in a fluid – handling process.

GE IC697ACC700: A communication module that enhances the networking capabilities of the GE IC697CPU731. It supports additional industrial protocols and can be used to connect the PLC to other devices in a more complex industrial network, such as integrating with a plant – wide Supervisory Control and Data Acquisition (SCADA) system.

GE Power Supply Module (Model: [specific model]): A dedicated power supply module for the GE IC697CPU731 that ensures stable and clean power supply. In industrial environments with fluctuating power, this power supply module helps to prevent power – related issues that could affect the performance and reliability of the CPU.

GE IC697CPU731 Expansion Rack: This expansion rack allows for the addition of more I/O modules to the GE IC697CPU731 system. In a growing manufacturing facility where the number of sensors and actuators is increasing, the expansion rack provides a convenient way to expand the control system’s capabilities without replacing the entire CPU.

GE Proficy Machine Edition: The software is essential for programming and configuring the GE IC697CPU731. It offers an intuitive user interface for creating, editing, and debugging control programs, as well as real – time monitoring of the CPU’s performance and the connected I/O devices.

GE Cable and Connector Kit: A pre – assembled kit of cables and connectors that simplifies the connection process between the GE IC697CPU731 and its associated I/O modules, sensors, and actuators. Using this kit reduces the risk of wiring errors and installation time, ensuring a quick and reliable connection in industrial applications.

GE IC697CPU731 Spare Parts Kit: This kit contains essential spare parts for the GE IC697CPU731, such as processors, memory modules, and communication chips. Having a spare parts kit readily available helps to minimize downtime in case of component failures, ensuring continuous operation of the industrial control system.

Installation, commissioning and maintenance instructions

Installation Preparation

Before installing the GE IC697CPU731, verify its compatibility with the existing control system components, including I/O modules, power supplies, and communication networks. Ensure that the installation environment meets the specified temperature, humidity, and electromagnetic interference requirements. Gather the necessary installation tools, such as a screwdriver, wire strippers, and a multimeter for electrical measurements. Safety precautions must be strictly followed; power off the entire control system and implement lockout/tagout procedures. Label all existing wiring and components to avoid confusion during the installation process.

Installation Process

Mount the GE IC697CPU731 in the designated slot of the control cabinet or rack. Secure it in place using the provided mounting hardware. Connect the power supply cables, ensuring that the correct voltage is applied and the polarity is correct. Connect the communication cables, such as Ethernet or serial cables, to the appropriate ports on the CPU. Then, connect the I/O modules to the CPU using the dedicated communication buses or cables. Make sure all connections are tight and secure.

Commissioning

Once the installation is complete, power on the control system. Use the GE Proficy Machine Edition software to detect the GE IC697CPU731 and configure its parameters. Set up the communication protocols, define the I/O addresses for the connected modules, and upload the control program. Test the communication interfaces by pinging other devices on the network. Test the I/O functionality by applying input signals (such as using a test switch for digital inputs) and verifying that the corresponding outputs respond as expected.

Maintenance Suggestions

For routine maintenance, regularly monitor the GE IC697CPU731‘s status through the GE Proficy Machine Edition software. Check for any error messages, abnormal communication status, or high CPU load. Conduct a visual inspection of the CPU and its connections on a monthly basis to look for signs of physical damage, loose wires, or overheating. Clean the CPU and its enclosure using a soft, dry brush to remove dust. Periodically perform diagnostic tests on the CPU’s memory and communication interfaces to ensure their proper operation. In case of a fault, use the software’s diagnostic tools to identify the problem. If the issue is with the CPU, replace it with a GE – approved spare CPU promptly to minimize downtime.

Service and guarantee commitment

The GE IC697CPU731 comes with a 12 – month manufacturer’s warranty from GE. This warranty covers any defects in materials, workmanship, or compatibility with the supported control systems. GE provides comprehensive technical support during regular business hours. Their team of experienced engineers, well – versed in the GE IC697CPU731 and related industrial control technologies, can be reached via phone or email for assistance with installation, programming, and troubleshooting. Customers also receive free access to the GE IC697CPU731 technical documentation, which includes detailed installation guides, programming manuals, and wiring diagrams, for 6 months after purchase. For customers with mission – critical industrial applications, GE offers optional on – site maintenance and system optimization services for a fee. These services are designed to ensure the long – term reliability and peak performance of the GE IC697CPU731 in industrial control environments.