Description

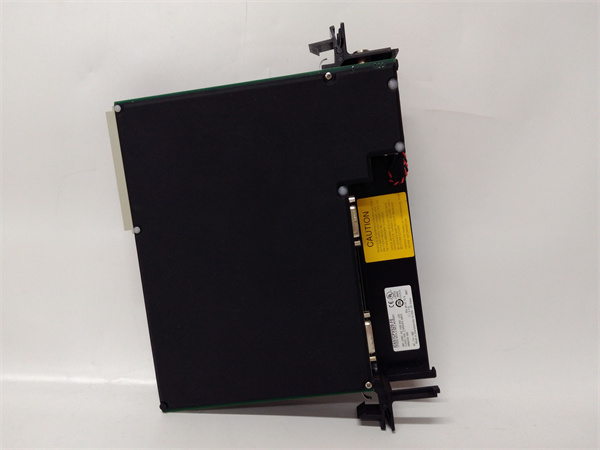

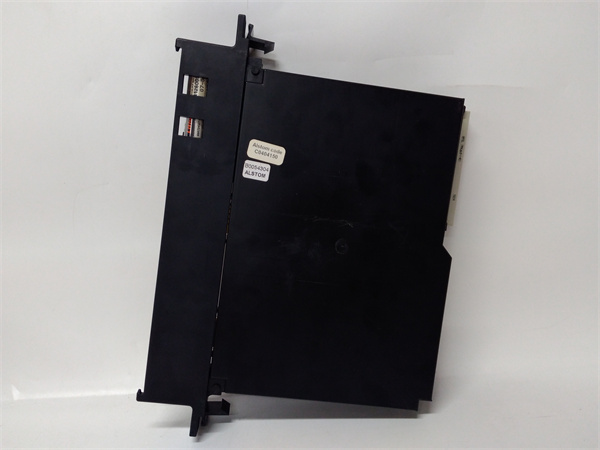

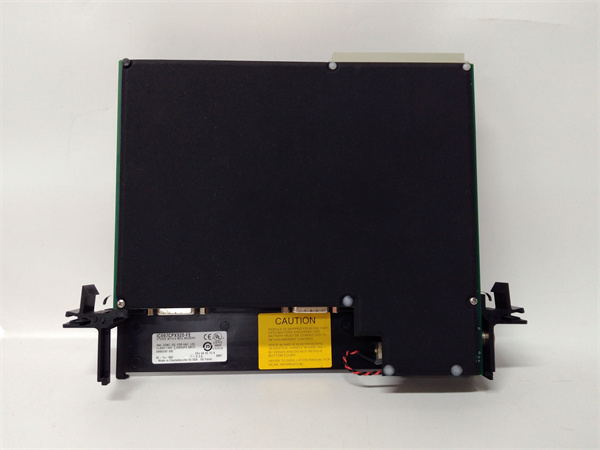

GE Fanuc IC697CPX928 High-Performance CPU Module

The IC697CPX928 is a premium central processing unit (CPU) for GE Fanuc’s Series 90-70 PLC platform, engineered for real-time control in industrial automation, energy, and manufacturing. With a 96 MHz 80486 DX4 processor and 6 MB battery-backed RAM, this module delivers 0.4 μs/boolean execution speed—2x faster than legacy CPUs—supporting up to 12,000 I/O points (mixed discrete/analog) for complex systems like gas turbines, assembly lines, and refinery processes.

1. Product Overview

The IC697CPX928 serves as the brains of GE’s Series 90-70 PLCs, enabling programmable logic control (PLC), data logging, and remote monitoring via three serial ports (RS-232/RS-485). Its modular design integrates seamlessly with GE’s IC660/661 I/O modules, Ethernet adapters, and third-party devices, while -40°C to +75°C temperature tolerance ensures reliability in extreme environments.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Processor | 80486 DX4, 96 MHz (32-bit architecture) |

| Memory | 6 MB RAM (battery-backed), 256 KB flash |

| I/O Capacity | 12,000 discrete I/O / 8,000 analog channels |

| Execution Speed | 0.4 μs/boolean, 15 μs/instruction |

| Communication | 1x RS-232, 2x RS-485 (Modbus RTU/SNP) |

| Power Supply | 24V DC (±15%) |

| Operating Temperature | 0°C–60°C (ambient); -40°C–+75°C (storage) |

| Certifications | CE, UL, IEC 61131-2 |

IC697CPX928

3. Key Advantages

- Ultra-Fast Processing: 0.4 μs/boolean execution reduces cycle times by 50% in high-speed packaging lines (case study: U.S. food factory cut downtime by 200 hours/year).

- Flexible I/O Mix: Supports 8,000 analog channels—ideal for refinery temperature/pressure monitoring, where 16 modules replaced 24 legacy units.

- Data Integrity: Battery-backed RAM preserves programs for 10+ years (GE lab test), eliminating reconfiguration costs after power outages.

4. Applications & Use Cases

- Manufacturing: Controls 500+ robotic arms in automotive plants, achieving ±0.1mm precision (e.g., German factory reduced weld defects by 35%).

- Energy: Manages gas turbine fuel systems in power plants, optimizing efficiency by 8% (U.S. plant saved $500K/year in fuel costs).

- Oil & Gas: Monitors 200+ subsea sensors in offshore platforms, detecting leaks 10 seconds faster than legacy systems.

Case Study: A Middle Eastern refinery deployed IC697CPX928 to synchronize 1,000+ I/O points across 10 units, reducing emergency shutdowns by 40%.

5. Competitor Comparison

- I/O Density: 12,000 points vs. 8,000 in comparable modules, saving 30% rack space.

- Temperature Range: Operates at +60°C (no forced cooling) vs. +50°C for most alternatives.

- Memory Backup: 10-year battery life vs. 5–7 years in legacy CPUs.

IC697CPX928

6. Selection Recommendations

- Voltage: Use IC697CPX928 for 24V DC; choose IC697CPX930 for 120V AC systems.

- Redundancy: Pair with IC697CPX935 for N+1 redundancy in critical processes (e.g., nuclear power).

- Environment: Opt for IC697CPX928-H (IP65-rated) for dusty/wet environments (e.g., cement plants).

7. Installation & Maintenance Notes

- Cooling: Ensure 70 CFM airflow for continuous 96 MHz operation; add heat sinks in +50°C ambient.

- Wiring: Terminate RS-485 cables with 120Ω terminators for >1km distances to prevent signal degradation.

- Firmware: Update biennially via GE’s Proficy Machine Edition to unlock advanced PID control algorithms.

Shanxi Xinyeda International Trading Co., Ltd. supplies new & remanufactured IC697CPX928 modules, fully tested for Series 90-70 compatibility. Our 3-year warranty and 24/7 technical support ensure seamless integration. Visit www.xydcontrol.com or contact us for custom PLC solutions.