Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

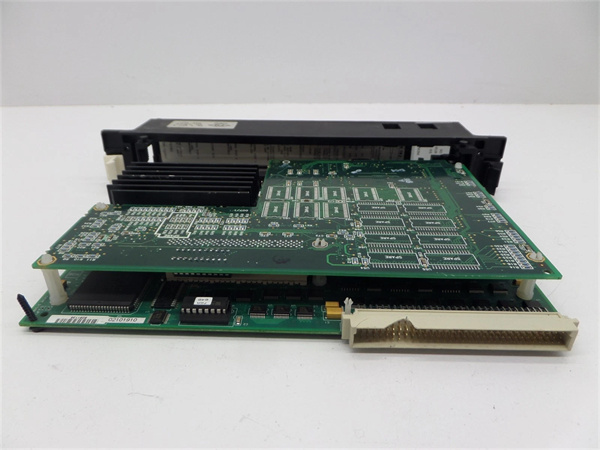

| Product model | GE IC697CPX928-CD |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | High-Performance CPU Module (90-70 Series PLC) |

| Processor Type | 32-bit RISC Processor; Clock Speed: 80 MHz |

| Memory Capacity | 1 MB Battery-Backed SRAM (data storage); 2 MB Flash Memory (program/firmware); Expandable via GE IC697MEM733 (up to 8 MB total) |

| I/O Capacity | Supports up to 4096 Digital I/O Points; 512 Analog I/O Points (via 90-70 expansion chassis) |

| Communication Interfaces | 2× Ethernet Ports (10/100 Mbps, Modbus TCP/IP, GE SNP); 1× RS-232/RS-485 Port (Modbus RTU); 1× Genius Bus Port (for distributed I/O) |

| Instruction Execution Speed | 0.2 μs per Basic Instruction (MOV, ADD); 1.5 μs per Complex Instruction (PID, Floating-Point Calculation) |

| Operating Temperature Range | 0°C to +60°C (Ambient); -20°C to +70°C (Short-Term Storage, <72h) |

| Power Requirements | 5V DC (from 90-70 Backplane); Current Draw: 0.6A Typical, 0.9A Peak |

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (Rack-Mount, 90-70 Chassis Slot 1); Weight: 450g |

| Protection Features | Built-in Watchdog Timer (1ms–10s Configurable); ESD Protection (±15kV Contact); Voltage Brownout Protection (4.5V–5.5V) |

| Status Indicators | Green LEDs (Power, Run, Communication Active); Red LED (Fault: Program Error, Hardware Failure); Amber LED (Warning: Low Battery, Communication Degradation) |

| Environmental Protection | Conformal Coating (IEC 60068-2-68, 2000h Salt Spray); EMI/RFI Shielding (EN 55022 Class A); IP20 Terminal Protection |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (Non-Incendive) |

| Compatibility | GE 90-70 PLC Chassis (GE IC697CHS010, GE IC697CHS020); 90-70 I/O Modules (GE IC697VAL134, GE IC697CMM712); 90-70 Power Supplies (GE IC697PWR710H); GE Proficy Machine Edition v9.0+ |

| Special Features | Supports Multi-Tasking (8 concurrent tasks); Built-in PID Control Blocks (up to 128 loops); Data Logging (up to 100,000 events) |

| MTBF (Mean Time Between Failures) | 600,000 hours (per MIL-HDBK-217F, 40°C ambient) |

GE IC697CPX928-CD

Product Introduction

GE IC697CPX928-CD is a high-performance CPU module engineered exclusively for GE’s 90-70 Series PLC systems, serving as the “control brain” for complex industrial automation applications that demand fast processing, extensive I/O support, and versatile communication. Unlike entry-level 90-70 CPUs (e.g., GE IC697CPU731), GE IC697CPX928-CD delivers enhanced processing power (80 MHz RISC processor), expanded memory (1 MB SRAM/2 MB Flash), and multi-interface connectivity—making it ideal for tasks like multi-loop PID control, large-scale data logging, and integration with enterprise-level SCADA systems.

As a flagship control component of the 90-70 ecosystem, GE IC697CPX928-CD plays a pivotal role in ensuring operational efficiency and reliability: its 0.2 μs basic instruction speed enables real-time response to dynamic process changes (e.g., adjusting chemical dosing in refineries), while its support for 4096 I/O points accommodates sprawling systems (e.g., automotive assembly lines with dozens of stations). For example, in a large-scale food processing plant, GE IC697CPX928-CD controls 12 PID loops (for temperature/flow regulation), logs 50,000 daily production events, and transmits data to a central MES via Ethernet—all while coordinating with GE IC697CMM712 communication modules and GE IC697VAL134 analog modules.

Core Advantages and Technical Highlights

80 MHz Processor for Ultra-Fast Control: GE IC697CPX928-CD’s 80 MHz RISC processor executes basic instructions in 0.2 μs—4x faster than GE IC697CPU731 (0.8 μs). This speed is critical for high-throughput processes like pharmaceutical batch manufacturing, where 100+ variables (temperature, pressure, mixing speed) must be monitored and adjusted in real time. A biotech plant using GE IC697CPX928-CD reduced batch cycle time by 15% (from 4 hours to 3.4 hours) by eliminating processing delays, increasing annual production capacity by 200,000 units.

Expandable Memory for Large-Scale Applications: With 1 MB SRAM and 2 MB Flash (expandable to 8 MB via GE IC697MEM733), GE IC697CPX928-CD stores complex programs (e.g., 500+ logic rungs for multi-station control) and long-term data logs. A municipal wastewater treatment plant expanded the module’s memory to 4 MB, enabling 6 months of hourly data logging (pH, turbidity, chemical usage) for regulatory compliance. This eliminated the need for external data loggers, saving $8,000 annually in hardware and maintenance costs.

Multi-Interface Connectivity for Seamless Integration: Equipped with 2× Ethernet ports, 1× RS-485 port, and 1× Genius Bus port, GE IC697CPX928-CD connects to diverse industrial systems. A automotive parts supplier uses one Ethernet port for Modbus TCP/IP communication with a SCADA system, the second for SNP communication with GE HMIs, and the Genius Bus port for distributed I/O (e.g., GE IC697BEM731 modules). This multi-protocol support avoided costly protocol converters, reducing system costs by $3,500 per installation.

Built-In PID and Multi-Tasking for Complex Control: GE IC697CPX928-CD includes 128 built-in PID blocks and supports 8 concurrent tasks—eliminating the need for specialty control modules. A chemical refinery using the module to control 24 distillation towers runs 8 tasks simultaneously (4 for PID control, 2 for data logging, 2 for alarm management). The built-in PID blocks maintained process stability within ±0.1% of setpoints, reducing product waste by 25% compared to systems relying on external PID controllers.

High MTBF for Mission-Critical Reliability: With a MTBF of 600,000 hours (40°C ambient), GE IC697CPX928-CD outperforms most industrial CPUs (average MTBF: 300,000 hours). A nuclear power plant’s auxiliary control system has operated GE IC697CPX928-CD for 7 years without failure, ensuring continuous monitoring of coolant flow and pressure—critical for preventing equipment overheating and maintaining plant safety.

Typical Application Scenarios

GE IC697CPX928-CD excels in complex, mission-critical automation applications across industries, with three high-impact use cases:

In oil & gas refining (100,000 barrels per day), GE IC697CPX928-CD controls a 90-70 system with 16× GE IC697VAL134 analog modules (monitoring reactor temperatures/pressures) and 8× GE IC697CMM712 communication modules (transmitting data to a plant-wide SCADA). Its 80 MHz processor adjusts 24 PID loops (for fuel/air ratio control) in 0.5 ms, ensuring optimal combustion efficiency and reducing CO2 emissions by 8% annually. The module’s Genius Bus port connects to 12 distributed I/O racks (via GE IC697BEM731), cutting wiring costs by 40% compared to a centralized I/O setup.

In automotive assembly (multi-model production), GE IC697CPX928-CD manages 8 assembly stations, each with 32 I/O points (proximity sensors, robotic grippers). Its 4096 I/O capacity supports 256 total I/O points, while multi-tasking runs 6 concurrent tasks (station control, quality checks, recipe management). When switching between car models (e.g., sedan to SUV), the module loads new recipes in <1 second—no downtime required. A Detroit-based plant using GE IC697CPX928-CD increased production flexibility, enabling 4 model changes per shift (up from 2 with older CPUs).

In pharmaceutical sterile manufacturing, GE IC697CPX928-CD controls 12 PID loops (for temperature, pressure, and airflow in cleanrooms) and logs 100,000+ batch data points daily. Its expandable memory (6 MB) stores 1 year of batch records for FDA 21 CFR Part 11 compliance, while Ethernet connectivity transmits real-time data to a validation server. The module’s ESD protection (±15kV) withstands electrostatic discharges common in cleanroom environments, preventing CPU resets that would invalidate batches. Over 3 years, the plant avoided 12 costly batch rejections (each costing $50,000) due to the module’s reliability.

GE IC697CPX928-CD

Related Model Recommendations

GE IC697CPU731: Mid-Range 90-70 CPU – Cost-effective alternative to GE IC697CPX928-CD for small-to-medium systems (e.g., 1000 I/O points, 10 PID loops) where ultra-fast processing is unnecessary.

GE IC697MEM733: 90-70 High-Capacity Memory Module – Expands GE IC697CPX928-CD’s memory to 8 MB, ideal for large programs or long-term data logging.

GE IC697PWR710H: 90-70 Power Supply – Provides stable 5V DC to GE IC697CPX928-CD, ensuring consistent processing performance and protecting against voltage fluctuations.

GE IC697CMM712: 90-70 Communication Module – Pairs with GE IC697CPX928-CD to add RS-485/Ethernet ports, enabling communication with remote sensors or SCADA systems.

GE IC697VAL134: 90-70 Analog Output Module – Works with GE IC697CPX928-CD to convert digital PID commands to analog signals (4–20mA) for controlling valves or pumps.

GE IC697BEM731: 90-70 Genius Bus Module – Extends GE IC697CPX928-CD’s I/O capacity via Genius Bus, supporting distributed I/O racks in large facilities.

GE Proficy Machine Edition v10.0: Programming Software – Configures GE IC697CPX928-CD (PID settings, data logging intervals) and monitors CPU health in real time.

GE IC697CHS020: 20-Slot 90-70 Chassis – Houses GE IC697CPX928-CD (Slot 1) and supporting modules (e.g., GE IC697MEM733, GE IC697CMM712) for dense system configurations.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697CPX928-CD, confirm compatibility with the 90-70 chassis (e.g., GE IC697CHS020) and power supply (GE IC697PWR710H). Ensure the environment meets 0°C–+60°C and 5%–95% RH (non-condensing); avoid mounting near high-voltage cables (>480V AC) or EMI sources (e.g., arc welders). Required tools: Torque screwdriver (0.6–1.0 N·m), ESD-safe gloves, multimeter, and Proficy Machine Edition v10.0+. Safety precautions: Disconnect chassis power; apply lockout/tagout to prevent electrical shock; handle the module by edges to avoid ESD damage.

Slide GE IC697CPX928-CD into 90-70 Chassis Slot 1 until it engages the backplane, then secure with chassis screws (torque to 0.8 N·m). Connect communication cables: Ethernet (CAT5e/CAT6) to SCADA/HMI, RS-485 to Modbus devices, and Genius Bus to distributed I/O. Power on the chassis; verify LEDs: green (power/run), no red (fault). Use Proficy Machine Edition to upload the control program, configure PID loops (setpoint, gain, integral time), and enable data logging. Test CPU responsiveness by simulating a sensor input change (e.g., increasing temperature) and confirming PID output adjustment within 0.5 ms.

Maintenance suggestions: For daily use, monitor GE IC697CPX928-CD’s LEDs—red LED indicates a fault (check Proficy for error codes: e.g., “program corruption,” “low battery”); amber LED signals warnings (replace backup battery if lit). Every 6 months, clean the module with compressed air (remove dust from vents) and retighten communication cables. Annually, back up the program to a PC, test the watchdog timer (simulate a program freeze to confirm reset), and replace the backup battery (GE part #IC697BAT001) to maintain SRAM data retention. If a hardware fault occurs, replace with a GE-approved GE IC697CPX928-CD spare—third-party CPUs may not support 90-70 backplane timing or PID features.

Service and Guarantee Commitment

GE IC697CPX928-CD is backed by a 48-month manufacturer’s warranty from GE—24 months longer than standard 90-70 CPUs—covering defects in materials, processing performance, and communication functionality under normal industrial use. If GE IC697CPX928-CD fails within the warranty period (e.g., processor error, Ethernet port failure), GE will repair or replace the module free of charge, including expedited shipping for critical systems (e.g., nuclear auxiliary control, pharmaceutical batch processing).

GE provides specialized technical support for GE IC697CPX928-CD, including 24/7 online resources (PID tuning guides, firmware updates, troubleshooting flowcharts) and dedicated industrial control engineers during business hours. For customers with complex deployments (e.g., refineries, automotive plants), GE offers on-site commissioning—verifying CPU performance, optimizing PID loops, and training technicians on advanced features (e.g., multi-tasking setup).

To extend the module’s lifecycle, GE recommends biennial “CPU health checks” (performed by GE-certified technicians) that include memory integrity testing, processor speed verification, and communication port validation. This commitment reflects GE’s confidence in GE IC697CPX928-CD’s durability, ensuring it delivers reliable control for 90-70 systems for 10+ years.