Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

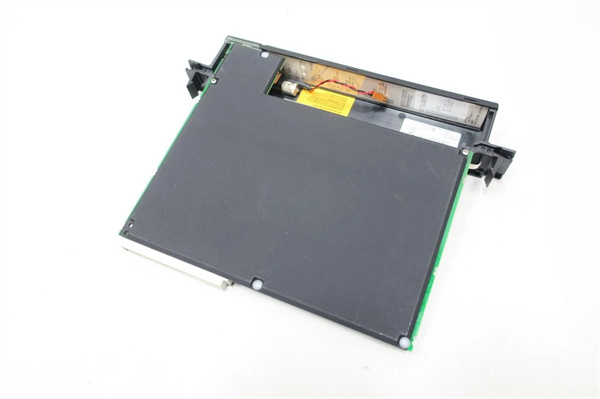

| Product model | GE IC697PCM711WMP |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Wireless Communication Module (90-70 Series Programmable Logic Controller) |

| Wireless Protocol | Wi-Fi (IEEE 802.11 b/g/n); Bluetooth Classic (v2.1+EDR) |

| Wireless Range | Wi-Fi: Up to 100m (line-of-sight); Bluetooth: Up to 10m (line-of-sight) |

| Wired Interfaces | 1× RS-485 (Modbus RTU); 1× Ethernet (10/100 Mbps, Modbus TCP/IP) |

| Supported Industrial Protocols | Modbus RTU (Wi-Fi/Bluetooth/Ethernet); GE SNP (Wi-Fi/Ethernet) |

| Security Features | Wi-Fi: WPA2/WPA3; Bluetooth: AES-128 Encryption; Password Protection for Configuration |

| Power Requirements | 5V DC (from 90-70 Backplane); Current Draw: 0.4A Typical, 0.6A Peak (Wi-Fi active) |

| Operating Temperature Range | -20°C to +60°C (Ambient); -30°C to +70°C (Short-Term Storage, <72h) |

| Physical Dimensions (H×W×D) | 160mm × 110mm × 45mm (Rack-Mount, 90-70 Series Form Factor); Weight: 420g |

| Environmental Protection | IP20 Terminal Protection; Conformal Coating (IEC 60068-2-68, 1000h Salt Spray); EMI/RFI Shielding (EN 55022 Class A) |

| Protection Features | ESD Protection (±15kV Contact); Overvoltage Protection (Up to 7V DC); Wireless Signal Interference Detection |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, FCC Part 15 (Wireless Compliance) |

| Compatibility | GE 90-70 PLC CPUs (e.g., GE IC697CPU731, GE IC697CPU780); 90-70 I/O Modules; Wireless Devices (HMIs, SCADA Clients, Mobile Apps); Proficy Machine Edition v10.0+ |

GE IC697PCM711WMP

Product Introduction

GE IC697PCM711WMP is a cutting-edge wireless communication module engineered exclusively for GE’s 90-70 Series PLC systems, serving as a “wireless bridge” that eliminates the limitations of wired networks in industrial automation. It integrates Wi-Fi and Bluetooth connectivity with traditional wired interfaces (RS-485, Ethernet), enabling flexible data transmission between 90-70 PLCs and remote devices—addressing the need for mobility, scalability, and cost savings in hard-to-wire environments (e.g., moving machinery, large facilities, or retrofits where wiring is impractical).

As a key communication component of the 90-70 ecosystem, GE IC697PCM711WMP stands out for its dual wireless protocol support, making it ideal for mixed-use cases: Wi-Fi for long-range, high-bandwidth data exchange (e.g., SCADA system integration), and Bluetooth for short-range, low-latency connections (e.g., mobile HMI for on-site troubleshooting). In automation systems, GE IC697PCM711WMP connects 90-70 CPUs (e.g., GE IC697CPU731) to wireless sensors, remote HMIs, or cloud-based platforms—for example, transmitting real-time production data from a rotating assembly line to a central SCADA system without costly cable runs, or enabling technicians to adjust PLC setpoints via a mobile app during equipment maintenance.

Core Advantages and Technical Highlights

Dual Wireless Protocols for Versatile Connectivity: GE IC697PCM711WMP supports both Wi-Fi (802.11 b/g/n) and Bluetooth (v2.1+EDR), adapting to diverse industrial needs. A large warehouse using 90-70 PLCs to control conveyor systems uses Wi-Fi to send 24/7 throughput data to a cloud dashboard (100m range), while technicians use Bluetooth to connect mobile HMIs (10m range) for on-the-spot fault diagnosis. This eliminates the need for separate Wi-Fi and Bluetooth modules, reducing backplane slot usage by 50% and simplifying system management.

Industrial-Grade Wireless Reliability: Unlike consumer-grade wireless modules, GE IC697PCM711WMP features EMI/RFI shielding, conformal coating, and interference detection—ensuring stable communication in noisy industrial environments. A metalworking plant using GE IC697PCM711WMP to connect wireless temperature sensors near arc welders experienced no signal drops, even amid high electromagnetic noise. Its interference detection automatically switches Wi-Fi channels if congestion is detected, maintaining 99.9% uptime—critical for time-sensitive processes like heat treatment.

Secure Data Transmission for Compliance: GE IC697PCM711WMP includes enterprise-grade security (WPA2/WPA3 for Wi-Fi, AES-128 for Bluetooth) and password-protected configuration, meeting data integrity requirements for regulated industries (e.g., pharmaceuticals, oil & gas). A pharmaceutical plant using the module to transmit batch data to a SCADA system ensured compliance with FDA 21 CFR Part 11—encrypted wireless data prevented unauthorized access, while audit logs tracked all configuration changes.

Seamless Wired-Wireless Integration: The module combines wireless connectivity with RS-485 and Ethernet ports, enabling hybrid networks that bridge legacy wired devices and new wireless systems. A water treatment plant retrofitting 90-70 PLCs used GE IC697PCM711WMP to connect existing wired flow sensors (via RS-485) and new wireless level sensors (via Wi-Fi), all transmitting data to a central PLC. This avoided a full system rewrite, saving $15,000 in retrofitting costs.

Typical Application Scenarios

GE IC697PCM711WMP excels in applications requiring wireless flexibility, with three high-impact use cases:

In automotive assembly, GE IC697PCM711WMP connects GE IC697CPU731 PLCs to wireless robotic arm sensors and a central SCADA system. Wi-Fi transmits real-time arm position data (100m range) to SCADA for production tracking, while technicians use Bluetooth-enabled tablets (10m range) to adjust calibration settings without disconnecting wired cables. During a recent maintenance cycle, this reduced downtime by 30%—technicians resolved alignment issues in 15 minutes vs. 45 minutes with wired HMIs.

In outdoor solar farms, GE IC697PCM711WMP links 90-70 PLCs (controlling inverter systems) to wireless weather sensors and a remote monitoring center. Wi-Fi sends inverter efficiency data (100m line-of-sight) to the center, while Bluetooth connects portable HMIs for on-site inverter testing. The module’s -20°C to +60°C operating range and conformal coating withstand extreme outdoor temperatures and dust, ensuring year-round reliability—critical for solar farms in desert or cold climates.

In food & beverage processing, GE IC697PCM711WMP enables wireless monitoring of rotating mixing tanks (where wired cables are prone to damage). The module connects wireless torque sensors on tanks (via Wi-Fi) to a 90-70 PLC, which adjusts mixing speeds based on real-time data. If a sensor detects abnormal torque (indicating a jam), the PLC uses the module’s Ethernet port to trigger an alarm in the control room. This prevented 12 costly tank repairs in one year, saving $24,000.

GE IC697PCM711WMP

Related Model Recommendations

GE IC697CMM712: Wired Serial Communication Module – Complements GE IC697PCM711WMP for applications needing additional wired RS-485/Ethernet ports (e.g., mixed wired-wireless networks).

GE IC697CPU731: 90-70 Mid-Range CPU – Pairs with GE IC697PCM711WMP to process wireless/wired data and execute control logic (e.g., solar inverter control, robotic arm synchronization).

GE IC697MEM719RR: 90-70 Memory Module – Expands PLC storage to log wireless sensor data (e.g., batch records, weather data) collected by GE IC697PCM711WMP.

GE Proficy Machine Edition v10.0: Programming Software – Configures GE IC697PCM711WMP (wireless settings, protocol mapping) and monitors wireless signal strength in real time.

GE IC697PWR101: 90-70 Power Supply – Provides stable 5V DC to GE IC697PCM711WMP (critical for consistent wireless performance, especially at peak current draw).

GE IC697BEM731: 90-70 Genius Bus Module – Adds wired Genius Bus connectivity to systems using GE IC697PCM711WMP for wireless, creating a hybrid network for large facilities.

GE Wireless Temperature Sensor (TC-WIFI-01): Industrial Wi-Fi Sensor – Optimized for GE IC697PCM711WMP, transmitting -200°C to +850°C data to 90-70 PLCs (ideal for heat treatment or refrigeration).

GE Bluetooth Mobile HMI (HM-BT-02): Handheld HMI – Connects to GE IC697PCM711WMP via Bluetooth for on-site PLC monitoring/troubleshooting (no wired connections required).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697PCM711WMP, confirm compatibility with the 90-70 CPU (e.g., GE IC697CPU731) and backplane revision (Rev. 3.0+). Ensure the installation location has unobstructed wireless line-of-sight (for Wi-Fi/Bluetooth) and meets -20°C to +60°C operating conditions. Required tools include a torque screwdriver (0.6–1.0 N·m), ESD-safe gloves, multimeter, Wi-Fi signal tester, and Proficy Machine Edition v10.0+. Always power off the 90-70 chassis and apply lockout/tagout to prevent electrical shock.

Mount GE IC697PCM711WMP in an empty 90-70 backplane slot, align the connector, and secure with M4 screws (torque to 0.8 N·m). For wired connections: link RS-485 devices to “A/B/GND” terminals (add 120Ω resistor for long distances) and Ethernet to the RJ45 port. For wireless setup: use Proficy Machine Edition to configure Wi-Fi (SSID, security mode) or Bluetooth (pairing code), and map protocols (e.g., Modbus RTU over Wi-Fi). Test connectivity by sending a test signal from a wireless sensor to the PLC—verify data reception within 100ms.

Maintenance suggestions: For daily operation, monitor GE IC697PCM711WMP’s status LEDs (green = normal wireless, amber = low signal, red = fault) and Proficy’s wireless dashboard (check signal strength, error rates). Every 6 months, clean the module with compressed air (avoid liquid cleaners) and inspect conformal coating for damage (repair with GE-approved coating if needed). Annually, test security features (verify WPA3/WPA2 is active, update passwords) and conduct range tests to ensure Wi-Fi/Bluetooth coverage hasn’t degraded. If signal drops occur, check for new obstacles (e.g., new machinery) and reposition the module or add wireless repeaters. Replace GE IC697PCM711WMP with a GE-approved spare if wireless chips fail or security features are compromised.

Service and Guarantee Commitment

GE IC697PCM711WMP is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, wireless performance (e.g., signal range, protocol compatibility), and security features under normal industrial use. If GE IC697PCM711WMP fails within the warranty period—for example, due to faulty Wi-Fi chips or conformal coating damage—GE will repair or replace the module free of charge, including return shipping for qualified claims.

GE provides specialized technical support for GE IC697PCM711WMP, including 24/7 online resources (wireless setup guides, interference troubleshooting checklists) and dedicated wireless engineering support during business hours. For customers with critical wireless networks (e.g., solar farms, regulated manufacturing), GE offers a “wireless optimization program”: on-site assessments to optimize signal coverage, security configuration, and protocol mapping—ensuring the module delivers 99.9% uptime.

To extend the lifecycle of GE IC697PCM711WMP, GE offers optional post-warranty services, including wireless firmware updates (to support new security standards like WPA3) and preventive maintenance checks. This commitment reflects GE’s confidence in GE IC697PCM711WMP’s industrial durability and ensures customers maximize the value of their 90-70 wireless communication infrastructure.