Description

Product Overview

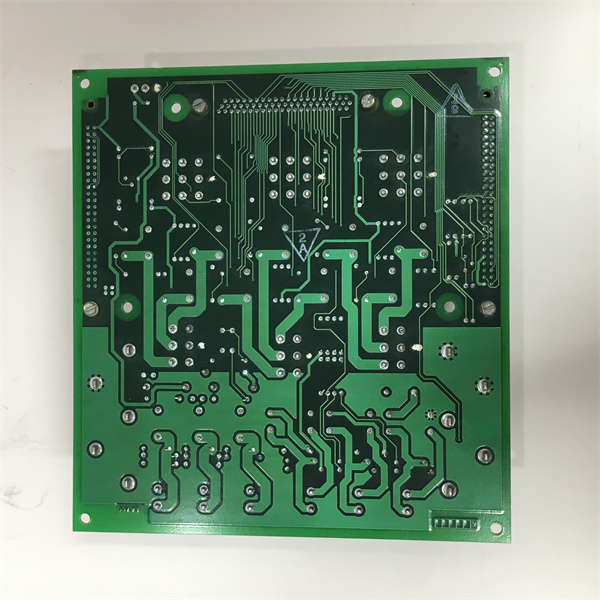

The GE Fanuc IC697VDD100 digital input module is a crucial component in industrial automation systems. Engineered by GE Fanuc, a renowned name in the field, this module is designed to offer precise and reliable data acquisition. It belongs to the high – performance IC697 series, which is known for its robustness and ability to operate in harsh industrial environments.

Featuring 16 digital input channels, the IC697VDD100 can efficiently acquire data from various sensors. It operates with a 24 VDC power supply, integrating seamlessly into existing systems. With its RS – 485 communication interface and Modbus RTU compatibility, it enables smooth data exchange between devices, enhancing the overall operational efficiency of the control system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697VDD100 |

| Manufacturer | GE Fanuc |

| Product Type | Digital Input Module |

| Number of Inputs | 16 |

| Input Voltage Range | 24 VDC |

| Current Capacity | 30 mA per channel |

| Communication Protocol Compatibility | Modbus RTU |

| Communication Interface | RS – 485 |

| Operating Temperature Range | – 40 °C to + 70 °C / – 10 °C to + 60 °C (varies by source) |

| Dimensions (WxHxD) | 114.3 mm x 90.5 mm x 51.8 mm / 84 mm x 145 mm x 124 mm (varies by source) |

| Weight | 0.3 kg / 0.5 kg / 1 kg (varies by source) |

| Environmental Rating | IP20 / IP30 (varies by source) |

Main Features and Advantages

Reliable and stable: The IC697VDD100 is built with high – quality materials, enabling it to withstand harsh industrial environments. It has a wide operating temperature range, ensuring consistent performance under various conditions.

Efficient data acquisition: With 16 digital input channels, it can collect data from multiple sensors simultaneously, improving the efficiency of data acquisition. Its Modbus RTU compatibility and RS – 485 communication interface ensure seamless data exchange with other devices in the control system.

Compact design: The module has a compact structure, which allows for easy installation in control panels, saving valuable space. Its panel – mount capability also contributes to a neat and organized installation.

Efficient data acquisition: With 16 digital input channels, it can collect data from multiple sensors simultaneously, improving the efficiency of data acquisition. Its Modbus RTU compatibility and RS – 485 communication interface ensure seamless data exchange with other devices in the control system.

Compact design: The module has a compact structure, which allows for easy installation in control panels, saving valuable space. Its panel – mount capability also contributes to a neat and organized installation.

Application Field

The IC697VDD100 is widely used in various industrial automation scenarios. In the manufacturing industry, it can be used to monitor the status of production equipment, such as the on – off state of motors and the position of valves, providing real – time data for production line control. In the oil and gas industry, it can withstand harsh outdoor environments and is used to detect the status of sensors in oil wells and pipelines, ensuring the safe operation of the production process. In the food processing industry, it can monitor the operation of food processing equipment and ensure the quality and safety of food production. In addition, it is also suitable for use in the logistics industry to monitor the operation of conveyor belts and automated warehouses.

Related Products

- IC697PWR711: This is a power supply module in the GE Fanuc IC697 series, which provides power for the IC697VDD100 and other modules in the series.

- IC697CPU311: A central processing unit module that works with the IC697VDD100 to process digital input signals and control the entire automation system.

- IC697MDL740: An analog input module that can be used in conjunction with the IC697VDD100 to handle both digital and analog signals in industrial control systems.

- IC697ALG220: A logic module that cooperates with the IC697VDD100 to perform logical operations on digital input signals and output control signals.

- IC697ACC700: A communication module that enhances the communication capabilities of the IC697VDD100 and other modules in the series, enabling them to communicate with other devices in the network.

Installation and Maintenance

Pre – installation preparation: Before installing the IC697VDD100, make sure the power is off and the installation environment meets the requirements. Check the dimensions of the control panel to ensure that the module can be properly installed. Clean the installation surface to prevent dust and debris from affecting the installation.

Maintenance recommendations: Regularly check the connection status of the IC697VDD100 to ensure that the connectors are firmly connected. Clean the module regularly to remove dust and dirt. Monitor the operating temperature and voltage of the module to ensure that they are within the specified range. If any problems are found, contact the professional maintenance personnel in time.

Maintenance recommendations: Regularly check the connection status of the IC697VDD100 to ensure that the connectors are firmly connected. Clean the module regularly to remove dust and dirt. Monitor the operating temperature and voltage of the module to ensure that they are within the specified range. If any problems are found, contact the professional maintenance personnel in time.

Product Guarantee

GE Fanuc provides a high – quality guarantee for the IC697VDD100 digital input module. The product comes with a one – year warranty, during which any quality problems will be solved by the manufacturer free of charge. The company also provides comprehensive technical support to help customers solve any problems encountered during use. With a professional after – sales service team, GE Fanuc is committed to ensuring the normal operation of the product and meeting the needs of customers.