Description

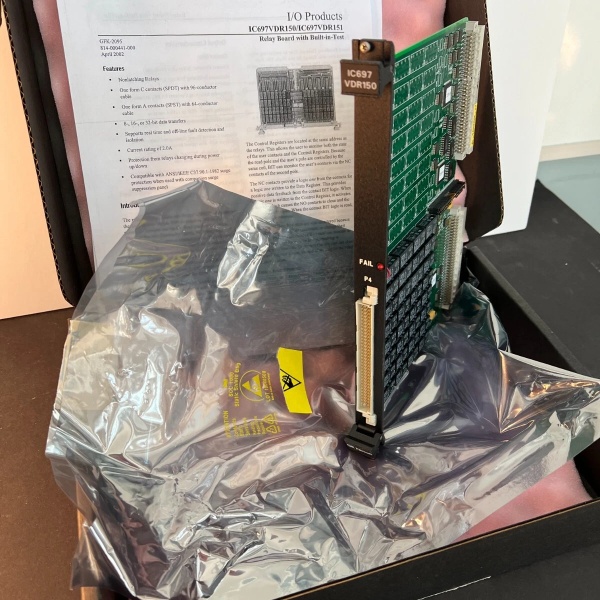

IC697VDR150: Product Overview

The GE IC697VDR150 is a 32-point discrete relay output module from GE’s Series 90-70 PLC family, a legacy platform renowned for its reliability in industrial automation. As part of the Series 90-70 ecosystem, it acts as a “switching interface” between the PLC controller and field devices (e.g., relays, solenoids), enabling precise control of industrial processes. Its primary role is to convert digital signals from the controller into physical actions (e.g., turning on a pump, activating a valve), which is critical for maintaining process stability and efficiency.

Role in Automation Systems:

Positioned as a “field output interface” in Series 90-70 architectures, the IC697VDR150 performs two primary functions:

-

Signal Conversion: Receives digital signals (0/24 V DC) from the PLC controller and converts them into high-current relay outputs (2 A per channel) to drive field devices.

-

Device Control: Sends control commands to field actuators (e.g., relays, solenoids) to adjust industrial processes (e.g., starting a conveyor belt, stopping a pump).

Core Functionality:

-

Relay-Based Outputs: Uses electromechanical relays for switching, which are suitable for both AC and DC loads (up to 250 V AC / 220 V DC). This makes it versatile for controlling a wide range of industrial devices.

-

Non-Latching Design: The relays are non-latching, meaning they return to their default state when the control signal is removed. This is ideal for applications where momentary activation is required (e.g., triggering a solenoid valve).

-

Galvanic Isolation: Optocouplers isolate field devices from the controller, protecting sensitive electronics from voltage spikes and electromagnetic interference (EMI) in harsh industrial environments.

-

Modular Design: Fits into standard Series 90-70 I/O racks, enabling easy expansion or replacement. The hot-swappable design minimizes downtime during maintenance.

Platform Benefits (Series 90-70):

The IC697VDR150 inherits the Series 90-70 platform’s strengths, including:

-

Reliability: The Series 90-70 system is the industry standard for industrial automation, with a proven track record of 24/7 operation in power plants, refineries, and manufacturing facilities worldwide.

-

Legacy Compatibility: The module is designed to work with existing Series 90-70 components (e.g., I/O racks, controllers), reducing the cost of system upgrades.

-

Scalability: Supports expansion with additional I/O modules (e.g., analog inputs, digital inputs) to accommodate growing system demands.

IC697VDR151

Technical Specifications

-

Model Number: IC697VDR150 (Variant of Series 90-70 PLC Family)

-

Manufacturer: GE (General Electric)

-

Product Type: Discrete Relay Output Module

-

Series: Series 90-70 (Industrial Automation)

-

Output Channels: 32 points (relay-based, non-latching)

-

Current Rating: 2 A per channel (resistive load, max 60 W per module)

-

Voltage Rating: 250 V AC / 220 V DC (max per channel)

-

Isolation: 1500 V AC (channel-to-channel, channel-to-logic)

-

Response Time: <10 ms (typical)

-

Bus Standard: VMEbus Rev. C.1 (supports A24/A32 addressing, D32/D16/D8 data transfer)

-

Operating Temperature: -20°C to +60°C (industrial-grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5–95% non-condensing

-

Weight: ~0.5 kg (1.1 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Reliable Device Control:

The IC697VDR150’s relay-based outputs and galvanic isolation ensure reliable control of field devices, even in electrically noisy environments. For example, in a power plant, the module can reliably activate a pump relay to maintain coolant flow, preventing turbine overheating.

2. Flexible Configuration:

The 32-point design allows engineers to customize the module’s functionality for different applications. For instance, in a manufacturing plant, the module can control multiple conveyor belts or robotic arms using a single module, reducing the need for additional hardware.

3. Rugged Industrial Design:

The module’s operating temperature range (-20°C to +60°C) and compact form factor make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets, reducing setup time and effort.

4. Easy Troubleshooting:

The module’s status LEDs (one per channel) provide instant visual feedback on output status, slashing troubleshooting time. For example, if a relay fails to activate, the corresponding LED will remain off, allowing technicians to identify the problem quickly.

IC697VDR151

Typical Applications

The GE IC697VDR150 is widely used in industrial automation systems for:

-

Power Generation:

-

Controls relays and solenoids in turbine control systems, ensuring stable power output.

-

-

Manufacturing:

-

Drives conveyor belts, robotic arms, and assembly line equipment in automotive and electronics manufacturing.

-

-

Petrochemical Industry:

-

Activates valves and pumps in refineries, ensuring safe and efficient operation in hazardous environments.

-

-

Water Treatment:

-

Controls pumps and valves in water treatment plants, maintaining proper flow and quality.

-