Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | IC698CPE020-CC |

| Manufacturer | GE (General Electric) |

| Product category | PLC Central Processing Unit (CPU) |

| Series compatibility | GE RX3i Series |

| Processor | 32-bit RISC processor, 800 MHz clock speed |

| Memory | 256 MB DDR3 RAM, 1 GB non-volatile flash memory |

| Programming capacity | Up to 100,000 instructions |

| Communication ports | 2 x Ethernet (10/100/1000 Mbps), 1 x USB 2.0, 1 x RS-232 |

| Supported protocols | EtherNet/IP, Modbus TCP/IP, Profibus DP (via expansion), GE SRTP |

| I/O capacity | Up to 8,192 digital points, 4,096 analog points |

| Operating temperature | 0°C to 60°C (32°F to 140°F) |

| Power supply | 24 VDC ±10%, 3.5 A typical consumption |

| Mounting | DIN rail or panel mount (via RX3i rack) |

| Certifications | UL 508, CE, ATEX Zone 2, IEC 61131-2 |

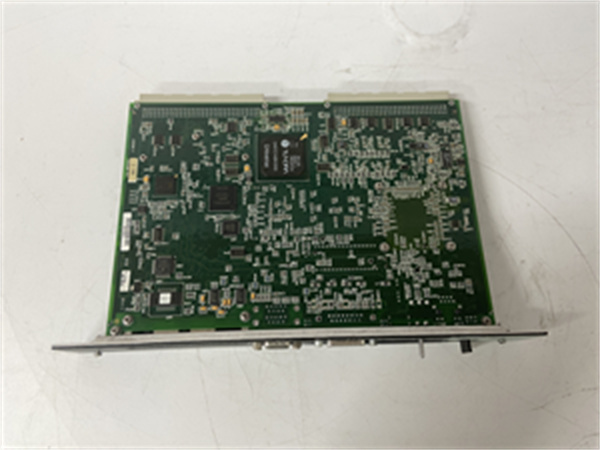

GE IC698CPE020-CC

Product Introduction

The GE IC698CPE020-CC is a high-performance central processing unit (CPU) belonging to GE’s RX3i Series of programmable logic controllers (PLCs). As the core of the RX3i system, this CPU is engineered to handle complex industrial automation tasks with precision and reliability.

Designed for mid to large-scale automation projects, the IC698CPE020-CC combines powerful processing capabilities with extensive connectivity options. Its 32-bit RISC processor and generous memory allow for the execution of sophisticated control algorithms while supporting large I/O configurations. Whether deployed in manufacturing, energy, or infrastructure applications, the GE IC698CPE020-CC serves as the brain of the automation system, coordinating data flow between sensors, actuators, and human-machine interfaces (HMIs) to ensure seamless operation.

Core Advantages and Technical Highlights

High-performance processing: The 800 MHz 32-bit RISC processor in the GE IC698CPE020-CC delivers rapid instruction execution, with a typical scan time of less than 1 ms for 10,000 instructions. This speed is critical in applications like high-speed packaging lines, where precise synchronization of multiple conveyors and robotic arms is required to maintain production throughput. The large memory capacity (256 MB RAM, 1 GB flash) supports complex logic and data logging without performance degradation.

Scalable I/O capability: Supporting up to 8,192 digital and 4,096 analog points, the IC698CPE020-CC adapts to growing automation systems. In automotive manufacturing plants, for example, it can start with controlling a single assembly line and expand to manage an entire factory floor by adding I/O modules. This scalability eliminates the need for CPU replacement during system expansions, reducing long-term costs.

Advanced communication features: Equipped with dual Gigabit Ethernet ports, the IC698CPE020-CC enables high-speed data exchange with HMIs, SCADA systems, and other PLCs. The ports support EtherNet/IP and Modbus TCP/IP, facilitating integration with both GE and third-party devices. In smart grid applications, this allows the CPU to communicate with energy management systems and remote monitoring platforms, enabling real-time grid optimization.

Robust reliability: Built to withstand industrial environments, the IC698CPE020-CC operates reliably in temperatures up to 60°C and features conformal coating options for protection against dust and moisture. Its ATEX Zone 2 certification makes it suitable for hazardous areas such as chemical processing plants, where equipment must meet strict safety standards. The CPU also includes built-in diagnostics that alert operators to faults, minimizing downtime through rapid troubleshooting.

Typical Application Scenarios

Industrial manufacturing: In a semiconductor fabrication plant, the GE IC698CPE020-CC controls cleanroom environmental systems, regulating temperature, humidity, and air pressure with precision. It processes data from thousands of sensors to maintain Class 100 cleanroom conditions, while coordinating with material handling robots to transport wafers between processing stations. The CPU’s fast response ensures that any deviation from set parameters triggers immediate corrective actions, preventing costly production defects.

Water and wastewater treatment: The IC698CPE020-CC manages filtration systems, chemical dosing pumps, and sludge handling equipment in wastewater plants. It monitors pH levels, turbidity, and flow rates via analog inputs, adjusting treatment processes in real-time to meet regulatory standards. Its Ethernet connectivity allows data transmission to municipal SCADA systems, enabling remote monitoring of water quality and plant efficiency.

Renewable energy systems: In solar power plants, the GE IC698CPE020-CC controls solar tracker systems, adjusting panel angles to maximize sunlight absorption. It collects data on irradiance, temperature, and energy output, optimizing power generation while coordinating with grid connection systems. The CPU’s robust design ensures reliable operation in outdoor environments, withstanding extreme temperature fluctuations and UV exposure.

GE IC698CPE020-CC

Related Model Recommendations

GE IC698CPE010-CC: A lower-power CPU in the RX3i Series, suitable for smaller applications that don’t require the full capacity of the IC698CPE020-CC.

GE IC698ETM001: An Ethernet expansion module that adds two additional Gigabit ports to the IC698CPE020-CC, enabling more complex network topologies.

GE IC698MDL645: A 32-channel digital input module that connects to the IC698CPE020-CC, ideal for monitoring limit switches and proximity sensors in manufacturing.

GE IC698ALG220: A 8-channel analog input module compatible with the IC698CPE020-CC, used to measure pressure, temperature, and flow in process control.

GE IC698HMI002: A 10-inch HMI panel that pairs with the IC698CPE020-CC, providing operators with real-time process visualization and control.

GE IC698PWR330: A redundant power supply module that ensures uninterrupted operation of the IC698CPE020-CC in critical applications like nuclear power plants.

GE IC698PRO100: A programming software package for configuring and debugging the IC698CPE020-CC, supporting IEC 61131-3 languages (LD, FBD, ST, etc.).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the GE IC698CPE020-CC, ensure the RX3i rack is properly mounted on a DIN rail or panel, with adequate ventilation (minimum 100 mm clearance above and below). Verify the power supply provides 24 VDC ±10% and use a surge protector to prevent voltage spikes. Gather tools including a torque screwdriver (for terminal connections), ESD wristband, and network cable tester. Review the system layout to confirm communication and I/O module placement, ensuring Ethernet cables are rated for industrial use (Cat 5e or higher).

Maintenance suggestions: Perform monthly visual inspections of the IC698CPE020-CC to check for loose connections, dust buildup, or overheating (indicated by hot spots or discoloration). Clean ventilation vents with compressed air to maintain cooling efficiency. Back up program data weekly to a secure server, and test restore procedures quarterly to ensure data integrity. Monitor CPU load via the HMI; sustained loads above 80% may indicate the need for optimization or expansion. Replace the lithium backup battery every 3-5 years to preserve configuration data during power outages. For troubleshooting, use the built-in web server to access diagnostic logs and error codes before attempting hardware replacements.

Service and Guarantee Commitment

GE offers a 36-month warranty for the GE IC698CPE020-CC, covering manufacturing defects and component failures under normal operating conditions. The company’s global technical support team provides 24/7 assistance via phone, email, and online chat, with on-site service available in major industrial regions.

Customers gain access to a comprehensive suite of resources, including firmware updates, programming manuals, and application examples, through GE’s industrial support portal. Training courses (both online and in-person) are available to help engineers master programming and maintenance of the IC698CPE020-CC. For mission-critical applications, GE offers extended warranty plans that include priority technical support, preventive maintenance, and rapid replacement services. This commitment ensures the GE IC698CPE020-CC delivers consistent performance throughout its operational lifecycle, backed by GE’s expertise in industrial automation.