Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

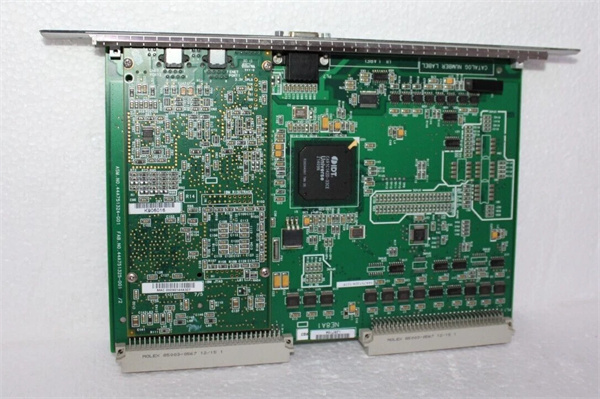

| Product model | GE IC698ETM001 |

| Manufacturer | GE Industrial (RX3i PLC Product Line) |

| Product category | Compact Ethernet Communication Module (for RX3i PLC Systems) |

| Supported communication protocols | EtherNet/IP (CIP), Modbus TCP/IP, TCP/IP Socket (Client/Server) |

| Ethernet ports | 1 x 10/100 Mbps RJ-45 port (auto-negotiation; full/half-duplex support) |

| Maximum network nodes | Up to 128 devices (via EtherNet/IP; dependent on network topology) |

| Power supply | Derived from RX3i chassis (5V DC, 50mA max power consumption) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 36.8 mm (W) × 106.7 mm (H) × 160 mm (D) (1.45 in × 4.2 in × 6.3 in) |

| Installation method | RX3i chassis mounting (compatible with 3-slot to 16-slot RX3i chassis) |

| Diagnostic functions | Port link/activity LEDs (green = link active, amber = data transfer), error logging (via Proficy Machine Edition) |

| Compatibility | All RX3i CPUs (e.g., GE IC695CPU310 RX3I, GE IC695CRU320-EN) and I/O modules |

| Shock/vibration resistance | 30 g peak shock (11 ms); 5 g peak vibration (10-2000 Hz) |

GE IC698ETM001

Product Introduction

The GE IC698ETM001 is a compact, cost-optimized Ethernet communication module in GE’s RX3i PLC family, designed to serve as a “network gateway” for small-to-medium industrial automation systems. Unlike bulkier multi-port communication modules, the GE IC698ETM001 delivers essential Ethernet connectivity in a single-slot form factor, making it ideal for applications where chassis space is limited but reliable network access is critical.

Technical positioning for industries like food packaging, regional water treatment, and discrete manufacturing (e.g., electronics assembly), the GE IC698ETM001 enables seamless data exchange between RX3i CPUs (such as the GE IC695CPU310 RX3I) and key industrial devices: EtherNet/IP-enabled HMIs, Modbus TCP-based remote sensors, and enterprise SCADA platforms. It eliminates the need for external gateways by natively supporting multiple protocols, simplifying network architecture. In automation systems, the GE IC698ETM001 acts as a “data bridge,” ensuring real-time control data and process metrics flow reliably between the PLC and upstream/downstream systems—all while keeping hardware costs and installation complexity low.

Core Advantages and Technical Highlights

Multi-Protocol Support for Flexible Integration: The GE IC698ETM001 natively supports EtherNet/IP (for seamless integration with GE’s RX3i ecosystem) and Modbus TCP/IP (for connecting to legacy third-party devices), eliminating the need for protocol converters. For example, a small electronics assembly line can use the GE IC698ETM001 to link a GE IC695CPU310 RX3I CPU to a GE Pro-face HMI (via EtherNet/IP) and a legacy Modbus TCP temperature controller—all through a single module, reducing wiring and component costs by 30%.

Compact Single-Slot Design: Occupying just one slot in RX3i chassis (e.g., IC695CHS008), the GE IC698ETM001 maximizes available space for I/O modules. A food packaging plant using a 4-slot chassis can fit the GE IC698ETM001, a GE IC695CPU310 RX3I, and two I/O modules (e.g., IC695DIA160-AA) without needing a larger chassis—saving cabinet space and lowering infrastructure costs.

Robust Industrial Durability: Built to withstand harsh industrial conditions, the GE IC698ETM001 resists 30 g peak shock and 5 g peak vibration—critical for environments like beverage bottling lines, where conveyor vibrations can damage less rugged modules. Its wide operating temperature range (0°C to 60°C) also ensures reliable performance in humid, temperature-fluctuating control cabinets, avoiding unplanned downtime due to environmental stress.

Simplified Configuration and Diagnostics: The GE IC698ETM001 is configured via GE’s Proficy Machine Edition software, with pre-built templates for common protocols that reduce setup time by 40% compared to generic Ethernet modules. Its integrated link/activity LEDs allow technicians to quickly verify network connectivity without software, while error logs (accessible via Proficy) provide detailed insights into issues like failed connections or packet loss—streamlining troubleshooting.

Typical Application Scenarios

In small-scale food packaging facilities (e.g., bakery snack wrapping lines), the GE IC698ETM001 connects a GE IC695CPU310 RX3I CPU to a local HMI and a SCADA dashboard. It transmits real-time production data (e.g., wrapping speed, package count) via EtherNet/IP to the HMI, allowing operators to adjust settings, and sends aggregated data via Modbus TCP to the SCADA system for plant-wide monitoring. The GE IC698ETM001’s compact design fits in the line’s 4-slot chassis, while its vibration resistance ensures uninterrupted operation alongside noisy wrapping machines.

For regional water treatment stations (serving 5,000 residents), the GE IC698ETM001 links a GE IC695CPU310 RX3I to remote Modbus TCP flow meters and a central SCADA system. It receives flow rate data from meters located 500m away (via Ethernet) and transmits pump status data to the SCADA system, enabling operators to remotely monitor and adjust treatment processes. The GE IC698ETM001’s low power consumption (50mA) aligns with the station’s energy efficiency goals, while its industrial temperature tolerance withstands the humid pump house environment.

In electronics assembly (e.g., printed circuit board (PCB) testing), the GE IC698ETM001 connects a GE IC695CPU310 RX3I to a test station HMI and a barcode scanner (via Modbus TCP). It sends PCB test results (pass/fail) to the HMI for operator visibility and logs scanner data (part IDs) for traceability. The GE IC698ETM001’s reliable data transmission ensures accurate test records, reducing the risk of defective PCBs reaching customers.

GE IC698ETM001

Related Model Recommendations

GE IC698ETM002: 2-port Ethernet module in the same RX3i family as GE IC698ETM001, ideal for systems needing dual network connections (e.g., separate HMI and SCADA networks).

GE IC695CPU310 RX3I: Entry-level RX3i CPU, fully compatible with GE IC698ETM001 for small-to-medium automation systems (e.g., food packaging lines).

IC695CHS008: 8-slot RX3i chassis, provides mounting space for GE IC698ETM001, a CPU, and up to 6 I/O modules in mid-sized applications.

IC695PWR120: 120V AC to 5V DC power supply module, delivers chassis power for GE IC698ETM001 and connected RX3i components.

IC695ALG808-AA: 8-channel analog input module, pairs with GE IC698ETM001 to send sensor data (e.g., temperature) from remote locations to the RX3i CPU.

IC695DIA160-AA: 16-channel digital input module, collects discrete data (e.g., limit switch status) for transmission to the CPU via GE IC698ETM001-connected networks.

GE IC695CRU320-EN: High-scalability RX3i CPU, compatible with GE IC698ETM001 for larger systems (e.g., water treatment plants with 100+ I/O points).

IC698ETM003: Gigabit Ethernet module, upgrade option for GE IC698ETM001 in high-bandwidth applications (e.g., video monitoring of production lines).

IC200EBI001: VersaMax Ethernet module, enables cross-platform communication between VersaMax I/O and GE IC698ETM001-connected RX3i systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC698ETM001, power off the RX3i chassis and verify the control cabinet meets environmental specs (0°C-60°C, 5%-95% non-condensing humidity). Required tools include an anti-static wristband (to prevent ESD damage), torque screwdriver (0.5-0.8 N·m for chassis screws), Cat5e/Cat6 Ethernet cable tester, and Proficy Machine Edition software (v9.0+). Align the GE IC698ETM001 with an empty communication slot in the RX3i chassis, push until it latches, and secure with front-panel screws—never hot-swap the module, as this may disrupt network connectivity. Use shielded Ethernet cables (max length 100m) to reduce electrical noise from nearby motors or VFDs.

Maintenance suggestions: Daily maintenance for GE IC698ETM001 involves checking the port LEDs (green = link active, amber = data transfer; red = fault). Every 6 months, use compressed air (≤40 psi) to clean dust from the module’s vents and inspect Ethernet cable connections for corrosion or looseness. If network communication fails, first test the cable and switch with a tester; if issues persist, use Proficy Machine Edition to review error logs (e.g., IP address conflicts). When updating firmware for GE IC698ETM001, use GE’s secure firmware tool—firmware can be loaded remotely via Ethernet without powering off the chassis, minimizing downtime.

Service and Guarantee Commitment

The GE IC698ETM001 comes with a 1-year manufacturer’s warranty, covering defects in materials and workmanship under normal industrial use. GE provides 24/7 technical support via phone, email, and online portals, with certified engineers specializing in RX3i Ethernet systems available to assist with GE IC698ETM001 configuration, protocol troubleshooting, and network integration.

Beyond warranty, GE offers on-site commissioning services for GE IC698ETM001, including network setup validation, protocol testing, and compatibility checks with existing RX3i CPUs and devices. Global service centers stock genuine spare parts, ensuring expedited replacement (typically 2-3 business days for urgent orders) to minimize downtime. GE’s quality commitment includes 100% factory testing of each GE IC698ETM001—validating protocol functionality, network stability, and industrial durability—to ensure it meets the reliability standards of small-to-medium industrial automation applications.