Description

Product Overview

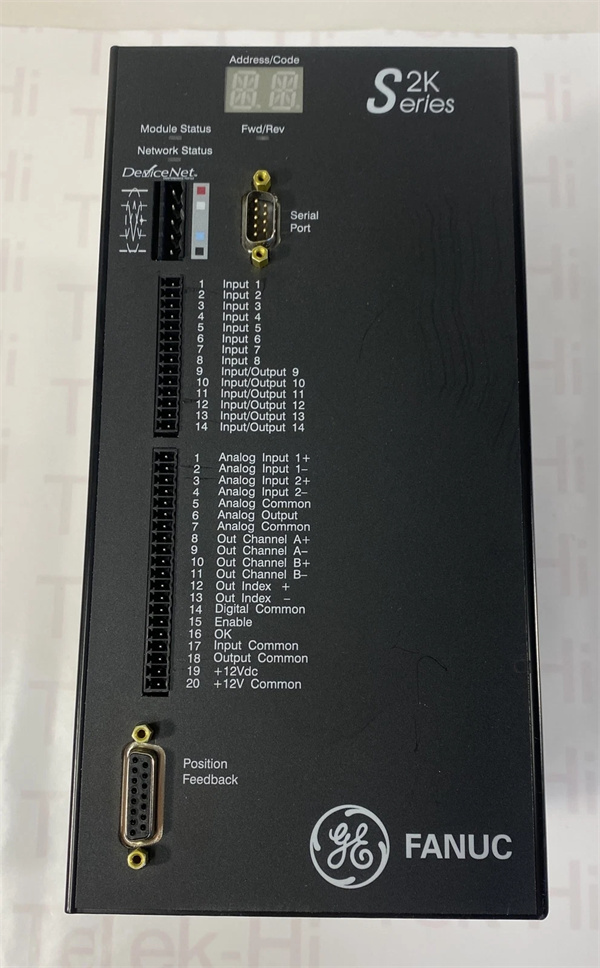

The GE IC800SSI216RD2 – CE is a highly sophisticated and reliable servo motor controller brought to you by GE Fanuc, a name synonymous with excellence in industrial automation. As an integral part of the S2K series, this controller is engineered to meet the demanding requirements of diverse industrial applications, providing precise control and seamless operation.

Designed to handle a 180 – 250 VAC 3 – phase input, the GE IC800SSI216RD2 – CE is a powerhouse when it comes to driving servo motors. It plays a crucial role in industrial setups where accurate control of motor speed, position, and torque is essential. With support for DeviceNet programming, it can easily integrate into existing industrial networks, enabling efficient communication between different components of the automation system. The controller comes equipped with position feedback mechanisms, a serial port, along with eight discrete inputs and outputs. This 丰富的 I/O 配置 allows it to interface with a wide range of sensors and actuators, further enhancing its versatility in industrial processes. The front panel of the device is user – friendly, displaying vital information such as module status, network status, address/code, and forward/reverse directions. The two – character LED display offers real – time diagnostic updates using mnemonic displays like “ok” for normal operation, “ov” for motor over – voltage, and “le” for lost enable, ensuring quick identification and resolution of any issues.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC800SSI216RD2 – CE |

| Manufacturer | GE Fanuc |

| Product Type | Servo Motor Controller |

| Input Voltage | 180 – 250 VAC, 3 – phase |

| Programming Support | DeviceNet |

| Position Feedback | Yes |

| Serial Port | Available |

| Discrete Inputs/Outputs | 8 each |

| Operating Temperature | 0 °C – 50 °C |

| Storage/Shipping Temperature | – 40 °C – 80 °C |

| Humidity | 5% – 95% non – condensing |

| Heat Sink Orientation | Must be vertical |

| Rated Altitude | Up to 3,300 feet |

| Installation Clearance | 3 inches on all sides for cooling |

| Compatible Motors | Mtr – 3S45 – H, Mtr – 3S46H, Mtr – 3S63 – G, Mtr – 3S65 – G, Mtr – 3S67 – G, Mtr – 3T45 – 1, Mtr – 3T54 – H, Mtr – 3T55 – H (continuous stall torque from 32 to 150.3 in – lb, rated speeds from 1,400 to 5,300 rpm) |

IC800SSI216RD2-CE

Main Features and Advantages

Precise Motor Control

The GE IC800SSI216RD2 – CE offers exceptional precision in controlling servo motors. Its advanced algorithms and position feedback capabilities ensure that the motor operates with high accuracy. This is especially crucial in applications such as precision manufacturing, where even the slightest deviation can lead to defective products. For example, in a micro – electronics manufacturing plant, the controller can precisely position robotic arms to place tiny components on circuit boards with micron – level accuracy.

Versatile Communication

With support for DeviceNet programming, the controller can communicate effectively with a wide range of industrial devices. This allows for seamless integration into complex automation systems. In a large – scale automotive assembly line, the GE IC800SSI216RD2 – CE can interact with other controllers, sensors, and actuators on the DeviceNet network, ensuring coordinated operation of all components involved in the assembly process.

User – Friendly Diagnostic Interface

The two – character LED display with mnemonic diagnostic updates simplifies the troubleshooting process. Operators can quickly identify issues just by glancing at the display. In an industrial environment where time is of the essence, this feature reduces downtime significantly. If the “ov” (over – voltage) message appears, maintenance staff can immediately check the power supply and related components to rectify the problem.

Wide Range of Compatible Motors

It is compatible with a diverse set of motors, providing flexibility in system design. Engineers can choose the most suitable motor for their application based on factors such as torque requirements and speed range. In a packaging industry, depending on the weight and speed of the packaging materials, an appropriate motor from the compatible list can be paired with the GE IC800SSI216RD2 – CE for optimal performance.

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC800SSI216RD2 – CE is extensively used. In a metalworking factory, it can control the servo motors of CNC machines. The precise control capabilities of the controller enable accurate cutting, drilling, and shaping of metal parts. In a textile manufacturing unit, it can drive the motors of weaving machines, ensuring consistent and high – quality fabric production by precisely controlling the movement of the loom components.

Automotive Industry

In automotive manufacturing, this controller is employed in various applications. It can be used to control the servo motors in robotic arms that assemble car parts. The ability to communicate over DeviceNet allows for seamless integration with other automation equipment on the production line. For example, it can work in tandem with sensors that detect the position of car bodies, and then precisely position the robotic arm to install components such as doors, engines, or seats.

Robotics and Automation

In robotic systems, the GE IC800SSI216RD2 – CE serves as a vital component. It can control the movement of robotic joints, enabling robots to perform complex tasks with precision. In a logistics warehouse, autonomous mobile robots (AMRs) equipped with this controller can accurately navigate through the warehouse, pick and place items, and transport them to the desired locations. The controller’s ability to handle position feedback and communicate with other devices in the automation system makes it an ideal choice for such applications.

Related Products

GE IC800SSI228RD2 – CE

This is another servo motor controller in the same product family. It likely has a different power rating or more advanced features compared to the GE IC800SSI216RD2 – CE. For instance, it might be able to handle higher voltage inputs or offer more complex control algorithms, making it suitable for applications with more demanding power or control requirements.

GE S2K Series Motors

Motors like Mtr – 3S45 – H, Mtr – 3S46H, etc., are designed to work in harmony with the GE IC800SSI216RD2 – CE. These motors have specific torque and speed characteristics that are optimized for use with this controller. Different motors in this series can be selected based on the specific needs of the industrial application, such as high – torque or high – speed requirements.

GE Industrial Sensors

Sensors such as position sensors and speed sensors can be connected to the GE IC800SSI216RD2 – CE. These sensors provide the necessary feedback for the controller to accurately control the servo motor. For example, a position sensor can inform the controller about the current position of the motor shaft, allowing the controller to make precise adjustments to achieve the desired position.

GE PLCs

Programmable Logic Controllers (PLCs) by GE can be integrated with the GE IC800SSI216RD2 – CE. The PLC can send control commands to the controller based on the overall logic of the industrial process. Different models of GE PLCs offer varying levels of processing power and memory, and the choice depends on the complexity of the application and the number of devices to be controlled in conjunction with the GE IC800SSI216RD2 – CE.

DeviceNet – Compatible Devices

Since the GE IC800SSI216RD2 – CE supports DeviceNet programming, a wide range of other DeviceNet – compatible devices can be connected to it. These include other controllers, actuators, and sensors. This compatibility allows for the creation of a comprehensive and integrated industrial automation network.

Installation and Maintenance

Pre – installation preparation

Before installing the GE IC800SSI216RD2 – CE, it is crucial to ensure that the power supply to the installation area is turned off to avoid electrical hazards. Check the power supply voltage to confirm it falls within the 180 – 250 VAC 3 – phase range required by the controller. Inspect the physical condition of the controller for any signs of damage during transportation. When preparing for installation, make sure to leave a clearance of 3 inches on all sides of the controller to facilitate proper cooling. Verify the compatibility of the controller with the motors, sensors, and other devices it will be connected to. Also, ensure that the heat sink orientation is set to vertical as required.

Maintenance recommendations

Regularly monitor the GE IC800SSI216RD2 – CE using the diagnostic display on the front panel. Check for any abnormal status messages such as “ov” or “le”. Clean the controller periodically to remove dust and debris, especially in dusty industrial environments, as these can affect the performance of the device. If any issues are detected, refer to the product manual for detailed troubleshooting steps. In case of component failures, use only genuine GE – approved replacement parts to maintain the controller’s performance and reliability. Periodically test the communication connections with other devices on the DeviceNet network to ensure seamless data transfer.

Product Guarantee

GE Fanuc stands behind the quality of the GE IC800SSI216RD2 – CE with a comprehensive product guarantee. The controller is manufactured using high – quality materials and advanced manufacturing processes to meet stringent industry standards. A warranty period is provided, during which, if there are any defects in materials or workmanship, GE Fanuc will repair or replace the controller free of charge. Their team of experienced technical experts is available to offer support for installation guidance, configuration assistance, and troubleshooting. This demonstrates GE Fanuc’s confidence in the product and its commitment to ensuring customer satisfaction in industrial automation applications. Whether it’s a small – scale manufacturing unit or a large – scale industrial complex, customers can rely on the GE IC800SSI216RD2 – CE and the support provided to keep their operations running smoothly and efficiently.