Description

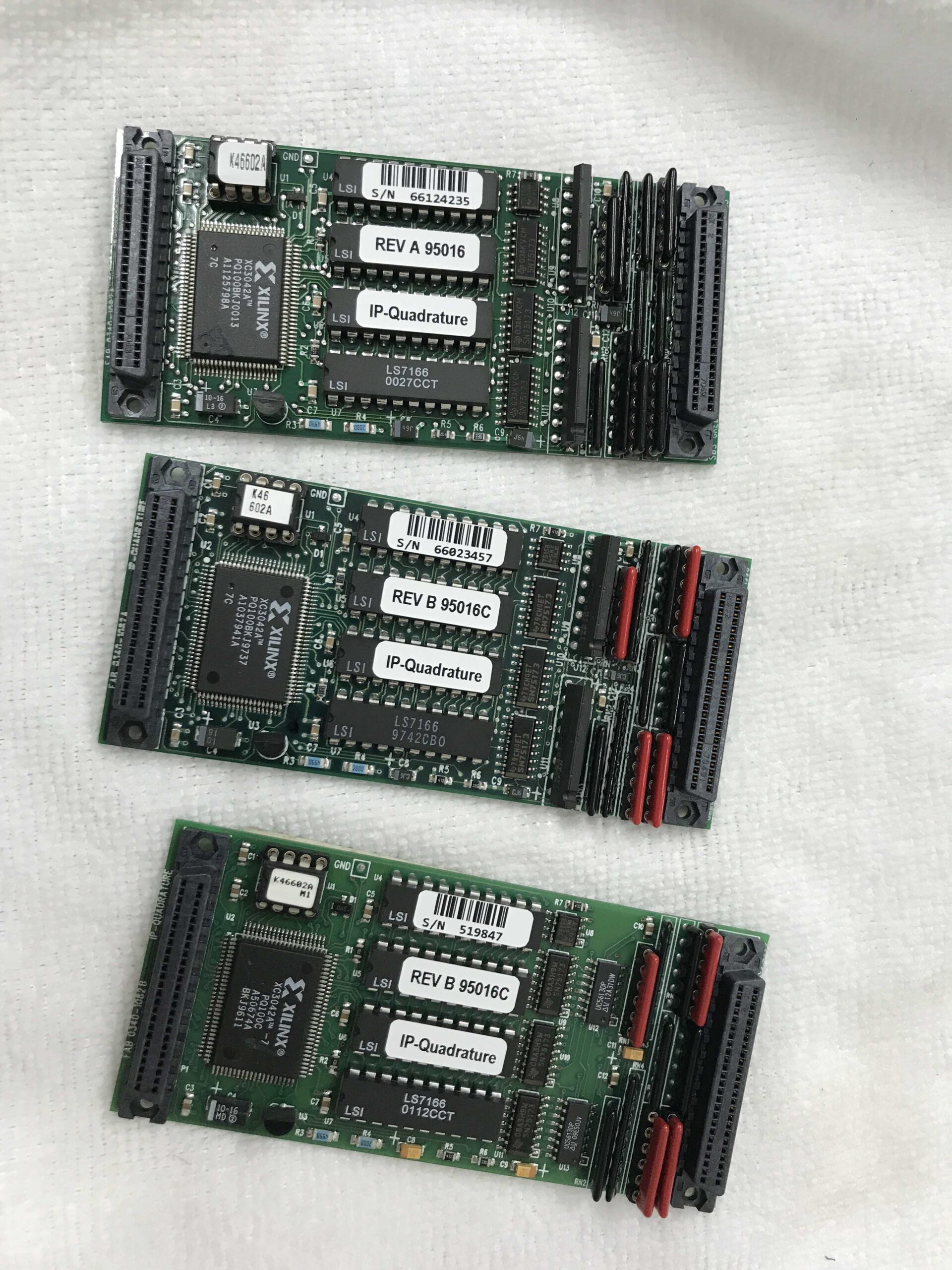

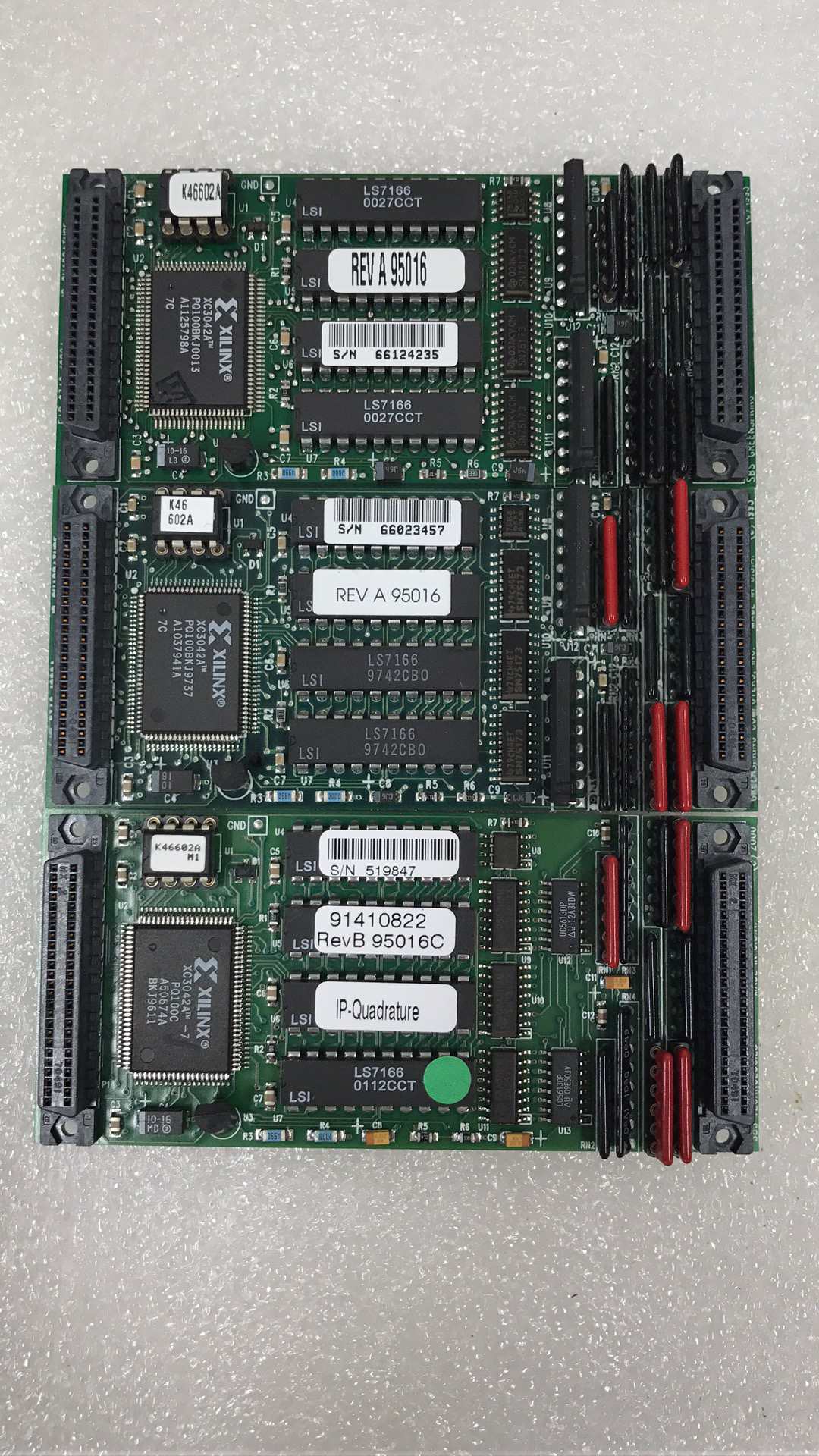

Product Overview

The GE IP – QUADRATURE is a high – performance quadrature encoder by General Electric, specifically engineered for industrial automation scenarios. As a key component in motion control systems, it excels at providing accurate position and speed feedback. With a design centered around four orthogonal decoder channels, the IP – QUADRATURE offers remarkable flexibility. Each channel can function independently and even be configured as a general – purpose counter. This makes it suitable for a wide range of applications where precise measurement of rotation or linear displacement is crucial.

In the industrial automation ecosystem, the GE IP – QUADRATURE plays a pivotal role in enhancing the efficiency and precision of manufacturing processes. It can be seamlessly integrated into various industrial control systems, whether it’s in a factory’s robotic arm control, CNC machine operation, or conveyor belt movement regulation. By delivering real – time and accurate data on motion parameters, it enables these systems to operate with high precision, minimizing errors and maximizing productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IP – QUADRATURE |

| Manufacturer | General Electric |

| Product Type | Quadrature Encoder |

| Encoder Resolution | 1024 – 4096 ppr (pulses per revolution) |

| Operating Voltage | 5 – 30 VDC |

| Output Signal | Quadrature A/B phase, index Z phase |

| Frequency Range | 0 – 10 kHz |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Protection Rating | IP67 |

| Mounting Style | Hub coupling |

| Weight | 0.5 kg |

| Dimensions | 50 mm x 50 mm x 30 mm |

| Interface | M12 connector, RS485, RS232 |

| Communication Protocol | Modbus RTU |

IP-QUADRATURE

Main Features and Advantages

High – Resolution Encoding

The GE IP – QUADRATURE offers an impressive encoder resolution ranging from 1024 to 4096 pulses per revolution. This high resolution allows for extremely accurate position sensing. In applications like semiconductor manufacturing, where precision down to the micron level is required for robotic arm movements, the IP – QUADRATURE ensures that the arm reaches the exact position, reducing the risk of errors in delicate processes such as chip placement.

Robust and Reliable Design

With an IP67 protection rating, the encoder is dust – tight and can withstand immersion in water up to a certain depth. This makes it suitable for harsh industrial environments, such as those in mining or food processing plants. The wide operating temperature range from – 40 °C to + 85 °C further enhances its reliability, as it can function optimally in extreme cold or hot conditions without performance degradation.

Versatile Connectivity Options

Featuring interfaces like M12 connector, RS485, and RS232, along with support for the Modbus RTU communication protocol, the GE IP – QUADRATURE can be easily integrated into existing industrial networks. It can communicate with different devices such as PLCs, HMIs, and other control systems, enabling seamless data transfer and control in complex industrial setups.

Application Field

Manufacturing Industry

In automotive manufacturing, the GE IP – QUADRATURE is used to control the movement of robotic arms on the assembly line. These arms need to precisely pick and place parts, and the encoder provides the necessary feedback to ensure accurate positioning. In a similar vein, in electronics manufacturing, it helps in the precise movement of pick – and – place machines, ensuring that tiny components are placed accurately on circuit boards.

Robotics

For industrial robots used in various applications, the IP – QUADRATURE is essential for accurate motion control. It enables robots to move with precision in tasks such as palletizing, where they need to stack items neatly. In collaborative robots working alongside human operators, the encoder ensures that the robot’s movements are predictable and safe, enhancing overall productivity in the workplace.

CNC Machining

In CNC machining centers, the GE IP – QUADRATURE plays a crucial role in controlling the movement of axes. It provides real – time feedback on the position of the cutting tool, allowing for high – precision machining. Whether it’s milling, drilling, or turning operations, the encoder ensures that the tool moves exactly as programmed, resulting in high – quality finished products.

IP-QUADRATURE

Related Products

GE PMC422 – LAM D2

This is a control module that can work in tandem with the GE IP – QUADRATURE. It helps in processing the data received from the encoder and translating it into control signals for other components in the industrial automation system.

GE PCH1026

It might be involved in signal processing related to the encoder’s output. It could potentially enhance the accuracy of the data or perform additional functions such as filtering noise from the encoder signals.

GE IC698CMX016

Although mainly a communication module, it can be used to transmit the encoder data over a network. It enables the GE IP – QUADRATURE to share its data with other devices in a distributed industrial control system.

GE DS200SIOBH1ABA

An analog input/output module, it can interface with the GE IP – QUADRATURE to transfer the encoder’s digital signals for further processing or to integrate them into a larger control system that involves both analog and digital components.

GE IS200WNPSH1ABA

A power supply module, it can ensure that the GE IP – QUADRATURE receives a stable power supply. A reliable power source is essential for the encoder to function accurately and consistently in industrial applications.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IP – QUADRATURE, ensure that the installation environment meets the specified requirements. Check the mechanical mounting area to ensure it is suitable for the hub coupling style. Verify that the power supply voltage is within the 5 – 30 VDC range. Inspect the encoder for any visible damage during transit. Also, make sure that the communication interfaces are compatible with the devices it will be connected to, such as ensuring proper cabling for the M12 connector, RS485, or RS232 interfaces.

Maintenance recommendations: Regularly inspect the GE IP – QUADRATURE for any signs of wear or damage, especially around the connection points. Clean the encoder periodically to keep dust and debris from affecting its performance, taking advantage of its IP67 protection rating. Monitor the operating temperature to ensure it remains within the – 40 °C to + 85 °C range. Check the encoder’s resolution and accuracy periodically by comparing its output with known reference values. If any issues arise, consult the user manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IP – QUADRATURE. The product comes with a standard one – year warranty, assuring customers that any manufacturing defects will be rectified at no cost. GE’s global technical support team is always available to assist customers. Whether it’s providing guidance during installation, troubleshooting operational issues, or answering questions about the encoder’s performance, the support team is committed to ensuring the GE IP – QUADRATURE operates optimally. This product guarantee not only reflects GE’s confidence in the product’s reliability but also its dedication to customer satisfaction in the industrial automation market.