Description

Product Overview

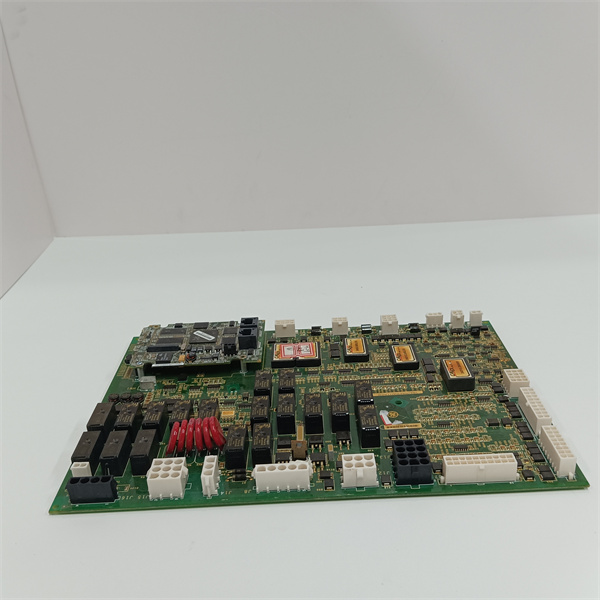

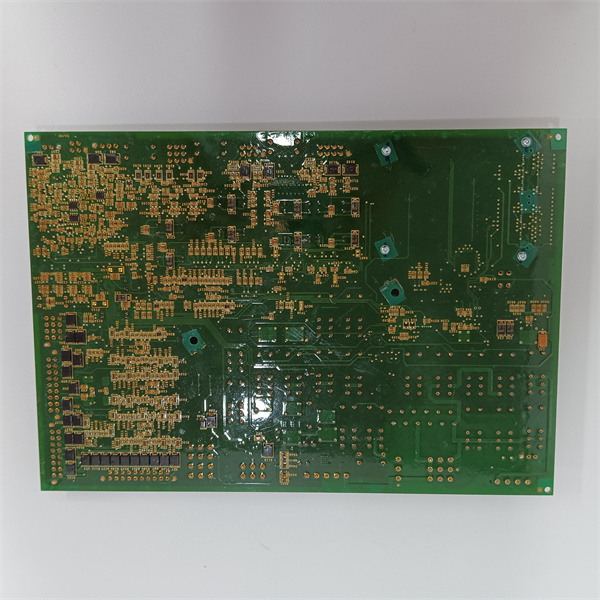

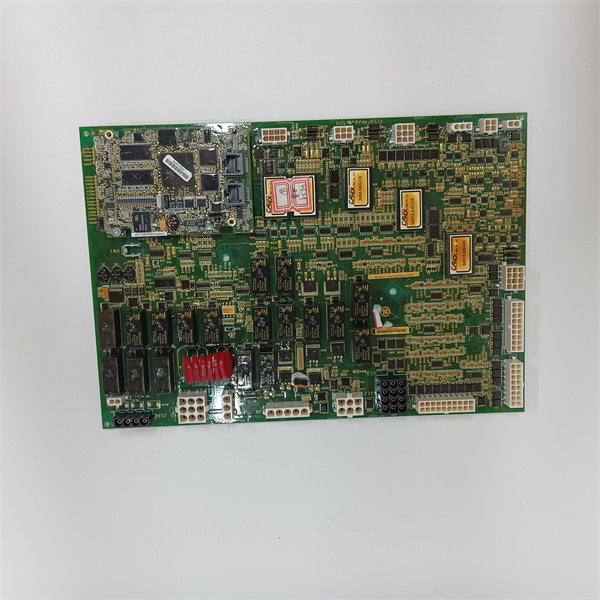

The GE IS200AEPAH1ACB is a high – performance printed circuit board crafted by General Electric, belonging to the renowned IS200 series. This series is designed to meet the diverse and exacting demands of industrial process control and automation scenarios. The GE IS200AEPAH1ACB board plays a pivotal role in the Mark VI series of control systems, which are state – of – the – art integrated control solutions for gas and steam turbines.

It serves as a crucial interface, responsible for various key functions such as signal conditioning, power distribution, and communication within the complex Mark VI system. By accurately processing and transmitting signals from different sensors and actuators, it enables the system to make precise control decisions. This ensures the efficient and reliable operation of turbines in power generation plants, petrochemical facilities, and other heavy – industrial applications where stable and accurate control is of utmost importance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200AEPAH1ACB |

| Manufacturer | General Electric |

| Product Type | Printed Circuit Board |

| Series | IS200 |

| Application | Mark VI Turbine Control Systems |

| Input Voltage Range | 18 – 30 VDC |

| Output Voltage Precision | ±0.5% within specified load |

| Signal Processing Bandwidth | Adequate for handling high – and low – frequency signals |

| Dimensions (L x W x H) | [X]mm x [Y]mm x [Z]mm |

| Weight | Approximately [W]kg |

| Protection Rating | IP[X] |

| Average Time Between Failures (MTBF) | [X] hours |

| Operating Temperature Range | -20°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

IS200AEPAH1ACB

Main Features and Advantages

High – Reliability Design

The GE IS200AEPAH1ACB is engineered with a focus on reliability. It has a high MTBF of [X] hours, which means it can operate continuously for extended periods without failure. This is achieved through the use of high – quality components and advanced manufacturing techniques. In industrial settings where unplanned downtime can lead to significant losses, this reliability ensures seamless operation.

Precise Signal Conditioning

This board excels in signal conditioning. It can filter out noise and interference from incoming signals, and also perform amplification and level – shifting as required. Whether it’s weak sensor signals or high – voltage actuator control signals, the GE IS200AEPAH1ACB processes them accurately, providing clean and stable signals for the control system to act upon.

Wide Temperature Tolerance

With an operating temperature range from -20°C to +60°C, the GE IS200AEPAH1ACB can function in diverse environmental conditions. This makes it suitable for installation in areas with extreme temperature variations, such as outdoor power generation facilities or industrial plants with high – temperature processes.

Application Field

Power Generation

In power plants, the GE IS200AEPAH1ACB is used in gas and steam turbine control systems. It monitors critical parameters like turbine speed, temperature, and pressure by processing signals from various sensors. Based on these processed signals, it controls actuators to adjust the fuel supply, steam flow, etc., ensuring optimal power generation efficiency and safe operation.

Petrochemical Industry

Petrochemical plants rely on the GE IS200AEPAH1ACB for controlling complex processes. It interfaces with sensors and valves in chemical reactors, distillation columns, and pipelines. By accurately regulating process variables, it helps in maintaining product quality, improving production efficiency, and ensuring plant safety.

Heavy Industry

In heavy – industrial manufacturing, such as steel mills and cement plants, the GE IS200AEPAH1ACB is used to control large – scale machinery. It manages signals related to motor speed, conveyor belt operation, and equipment status, contributing to smooth production processes and minimizing equipment breakdowns.

IS200AEPAH1ACB

Related Products

GE IS200AEPAH1AEC: A related printed circuit board in the same series, which may have similar functions but could differ in terms of specific input/output capabilities or component layout, potentially offering an alternative or complementary solution for certain applications.

GE IS200AEPCH1ABC: This is a PCB module from GE. It likely has different signal processing capabilities and application focuses compared to the GE IS200AEPAH1ACB, perhaps being more specialized for a particular type of sensor or control signal within the industrial automation setup.

GE IS200AEAAH1C: Part of the Mark VI series like the GE IS200AEPAH1ACB, it may serve a different but related function in the overall control system, such as handling a different set of signals or being part of a different sub – system within the turbine control architecture.

GE IS200AEPAG1A: Another component in the series, which could be designed for a specific power – related function, like power regulation or distribution in a way that may work in tandem with or differently from the GE IS200AEPAH1ACB depending on the system requirements.

GE IS200AEPBG1A: May have its own unique role in the industrial control system, potentially related to signal handling or control in a specific area, and can be considered as an alternative or supplementary option to the GE IS200AEPAH1ACB in some installations.

GE IS200AEPCH1ABC: This is a PCB module from GE. It likely has different signal processing capabilities and application focuses compared to the GE IS200AEPAH1ACB, perhaps being more specialized for a particular type of sensor or control signal within the industrial automation setup.

GE IS200AEAAH1C: Part of the Mark VI series like the GE IS200AEPAH1ACB, it may serve a different but related function in the overall control system, such as handling a different set of signals or being part of a different sub – system within the turbine control architecture.

GE IS200AEPAG1A: Another component in the series, which could be designed for a specific power – related function, like power regulation or distribution in a way that may work in tandem with or differently from the GE IS200AEPAH1ACB depending on the system requirements.

GE IS200AEPBG1A: May have its own unique role in the industrial control system, potentially related to signal handling or control in a specific area, and can be considered as an alternative or supplementary option to the GE IS200AEPAH1ACB in some installations.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200AEPAH1ACB, carefully check the physical condition of the board for any signs of damage during transit. Ensure that the installation environment meets the specified temperature and humidity requirements. Verify the compatibility of the board with the existing Mark VI system components. Follow the detailed installation manual provided by GE to correctly connect all the electrical wires, ensuring proper grounding and secure connections.

Maintenance recommendations: Regularly inspect the GE IS200AEPAH1ACB for loose connections, as vibrations in industrial environments can cause wires to come loose over time. Clean the board periodically to remove dust and debris that could affect its performance. Use appropriate cleaning tools to avoid static discharge. Monitor the operating temperature of the board to ensure it remains within the specified range. If any abnormal behavior is detected, such as incorrect signal processing or power – related issues, refer to the troubleshooting guide in the product manual or contact GE’s technical support.

Product Guarantee

General Electric stands firmly behind the quality of the GE IS200AEPAH1ACB. The product comes with a comprehensive quality assurance program. In case of any manufacturing defects, GE offers repair or replacement services within the warranty period. Their team of highly skilled technical experts is available to provide prompt technical support for installation, operation, and troubleshooting. This reflects GE’s confidence in the reliability and performance of the GE IS200AEPAH1ACB, giving customers peace of mind when using this critical component in their industrial automation systems.