Description

Product Overview

The GE IS200DTAIH1ABB is a printed circuit board meticulously crafted by General Electric for its renowned Mark VI series, which is part of the esteemed Speedtronic product line. Since the 1960s, the Speedtronic series has been a cornerstone in turbine management, with the Mark VI system specifically designed to manage gas/steam turbines. This system comes equipped with Ethernet communication capabilities and onboard diagnostics, both in hardware and software, ensuring seamless operation and easy troubleshooting.

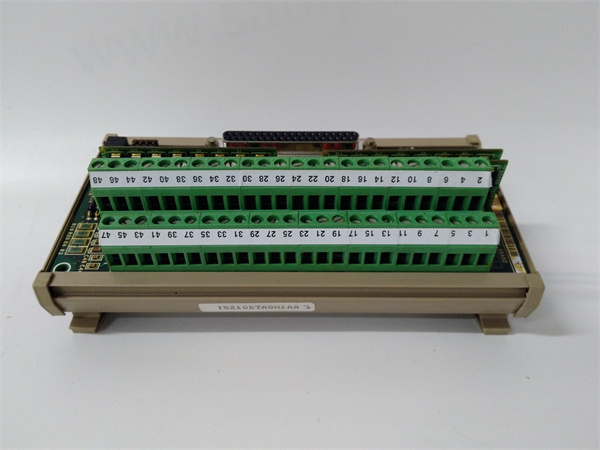

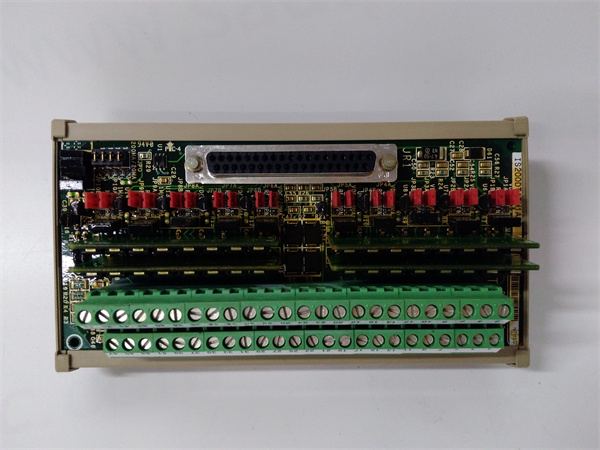

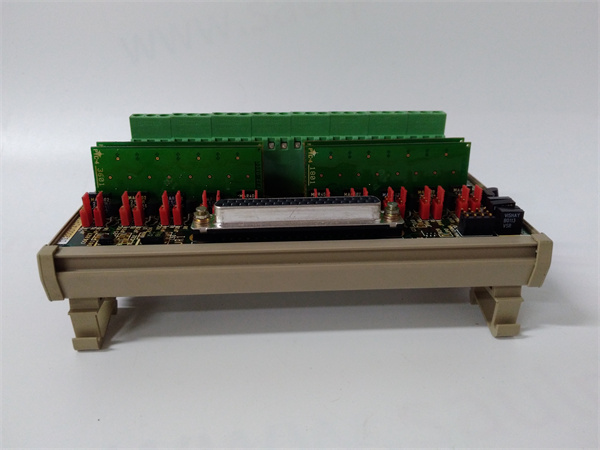

As a simplex analog input/output terminal board, the IS200DTAIH1ABB is a compact solution for handling analog signals. It is mounted in a plastic holder that enables din – rail mounting, making installation in industrial control panels convenient. With ten analog inputs and two analog outputs, it serves as a crucial interface for various analog – based sensors and actuators in industrial setups. The outputs can be configured, with one of them adjustable from 0 – 20 mA to 0 – 200 mA by reconfiguring jumpers, providing flexibility for different applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200DTAIH1ABB |

| Manufacturer | General Electric (GE) |

| Product Type | Printed Circuit Board (Simplex Analog Input/Output Terminal Board) |

| Series | Mark VI, Speedtronic |

| Inputs | 10 analog inputs |

| Outputs | 2 analog outputs (0 – 20 mA standard, one configurable to 0 – 200 mA via jumpers) |

| Connector | Single 37 – pin connector (JR1) with latching fasteners |

| Terminal Board | TB1 with 48 screw connections, permanently mounted; typically uses shielded twisted pairs of #18 AWG wire |

| Ground Connection | Screws 43/44 designated as ground (SCOM); ground wire should be as short as possible |

| Jumpers | Twenty – one jumper switches (JP1A/B – JP10A/B plus JP0) for configuring current and voltage |

| Mounting | Plastic holder for din – rail mounting |

| Associated Systems | GE Mark VI gas/steam turbine management system |

IS200DTAIH1ABB

Main Features and Advantages

Compact and Convenient Mounting

The GE IS200DTAIH1ABB‘s compact design, combined with its din – rail mounting capability, allows for easy integration into existing control panels. The plastic holder provides a secure and stable mounting solution, saving space in industrial cabinets where space is often at a premium. This not only simplifies installation but also makes maintenance and replacement more straightforward, reducing downtime in case of component failure.

Versatile Analog I/O Configuration

With ten analog inputs, it can interface with a wide range of sensors, such as temperature sensors, pressure transducers, and flow meters, gathering crucial data from the industrial process. The two analog outputs offer flexibility in controlling actuators. The ability to reconfigure one of the outputs from 0 – 20 mA to 0 – 200 mA through jumpers means it can be tailored to different types of equipment, whether it’s a valve actuator that requires a specific current range or a motor drive with unique input requirements.

Easy Configuration via Jumpers

The twenty – one jumper switches on the board, labeled JP1A/B – JP10A/B plus JP0, provide an intuitive way to configure current and voltage settings. This allows technicians to quickly adapt the board to the specific requirements of the industrial application without the need for complex software programming. For example, if the input signals from sensors have different voltage levels in a new installation, the jumpers can be adjusted to ensure proper signal conditioning and compatibility.

Application Field

Power Generation

In power plants, especially those with gas or steam turbines, the GE IS200DTAIH1ABB plays a vital role. It can be used to interface with sensors that monitor turbine temperature, vibration, and pressure. The analog inputs gather this data, which is then processed by the Mark VI system to ensure the turbine operates at optimal efficiency. For instance, temperature sensors connected to the board can help in early detection of overheating issues, preventing damage to the turbine. The analog outputs can control actuators that adjust the fuel supply or the position of turbine blades, optimizing power generation.

Industrial Manufacturing

Manufacturing plants that use analog – based control systems can benefit from the IS200DTAIH1ABB. In a chemical manufacturing process, it can be used to interface with sensors that monitor chemical concentrations, flow rates, and reaction temperatures. The board’s analog inputs collect this data, and the outputs can control valves that regulate the flow of chemicals or pumps that transfer materials. In a food and beverage factory, it can be used to control the filling levels of containers by interfacing with level sensors and controlling the filling machinery through its analog outputs.

Oil and Gas Industry

Within the oil and gas sector, the board is used in various applications. It can be installed in oil refineries to interface with sensors on pipelines, monitoring parameters like oil flow, pressure, and temperature. The analog inputs gather this data, and the outputs can be used to control valves that regulate the flow of oil or gas. In offshore platforms, where space is limited, the compact and din – rail mountable IS200DTAIH1ABB can be easily integrated into the control system. It can also be used in gas processing plants to manage the processing of natural gas, ensuring safe and efficient operations.

IS200DTAIH1ABB

Related Products

- GE IS200DTCIH1ABB: This is also a PCB component for the GE Mark VI Speedtronic Series. It functions as a DIN rail contact input board, similar to the IS200DTAIH1ABB, but may have different input/output configurations or be optimized for different types of contact – based sensors.

- GE Mark VI Other I/O Boards: There are other input/output boards in the Mark VI series, such as digital I/O boards. These boards are designed to handle digital signals instead of analog ones like the IS200DTAIH1ABB. They can be used in combination with the IS200DTAIH1ABB to create a comprehensive I/O solution for more complex industrial control systems.

- GE Speedtronic Series Upgrades: Newer versions or upgrades within the Speedtronic series may offer enhanced features compared to the Mark VI system where the IS200DTAIH1ABB is used. These upgrades could include better communication capabilities, more advanced diagnostic tools, or improved processing power, which may require compatibility considerations with the existing IS200DTAIH1ABB board.

- GE – Branded Analog Signal Conditioners: These are separate devices that can be used in conjunction with the IS200DTAIH1ABB to further condition analog signals. They can help in filtering out noise, amplifying weak signals, or converting signals to a more suitable format before they are fed into the board’s analog inputs.

- GE Turbine Control Modules: Other control modules in the GE turbine control product line can work in tandem with the IS200DTAIH1ABB. These modules may be responsible for overall turbine control algorithms, while the IS200DTAIH1ABB focuses on analog signal input and output functions.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200DTAIH1ABB, ensure that the power to the entire Mark VI system is switched off to avoid electrical hazards. Check the compatibility of the board with the existing Mark VI setup, including the type of sensors and actuators it will interface with. Inspect the board for any visible damage during transit. Mount the plastic holder on the din – rail according to the provided instructions. Connect the shielded twisted pairs of #18 AWG wire to the terminal board (TB1) securely, making sure to use the correct screw connections. Pay special attention to the ground connection at screws 43/44, ensuring the ground wire is as short as possible for proper electrical grounding.

Maintenance recommendations: Regularly check the IS200DTAIH1ABB for any signs of overheating, such as discolored components or an abnormal smell. Clean the board periodically to remove dust and debris, which can affect its performance. Monitor the analog input and output signals using appropriate measuring equipment to ensure they are within the expected range. If there are any signal anomalies, check the jumpers to ensure they are still correctly configured. Check the connection points on the terminal board and the 37 – pin connector for any signs of looseness or corrosion. In case of a malfunction, refer to the GE – provided manuals for troubleshooting steps or contact GE’s technical support for assistance. Replace any damaged components with genuine GE parts to maintain the integrity and performance of the board.

Maintenance recommendations: Regularly check the IS200DTAIH1ABB for any signs of overheating, such as discolored components or an abnormal smell. Clean the board periodically to remove dust and debris, which can affect its performance. Monitor the analog input and output signals using appropriate measuring equipment to ensure they are within the expected range. If there are any signal anomalies, check the jumpers to ensure they are still correctly configured. Check the connection points on the terminal board and the 37 – pin connector for any signs of looseness or corrosion. In case of a malfunction, refer to the GE – provided manuals for troubleshooting steps or contact GE’s technical support for assistance. Replace any damaged components with genuine GE parts to maintain the integrity and performance of the board.

Product Guarantee

GE stands firmly behind the quality of the GE IS200DTAIH1ABB printed circuit board. The product typically comes with a comprehensive warranty, the duration of which is clearly stated in the product documentation. During this warranty period, if there are any manufacturing defects, GE will, at its discretion, repair or replace the board free of charge. GE’s global network of technical support teams is available around the clock. Whether it’s providing guidance during installation, helping with configuration, or troubleshooting operational problems, GE’s experts are committed to ensuring the optimal performance of the IS200DTAIH1ABB. With strict quality control measures implemented throughout the production process, GE demonstrates its confidence in the reliability of this board, reflecting its long – standing dedication to customer satisfaction in the industrial automation and turbine control markets.