Description

Product Overview

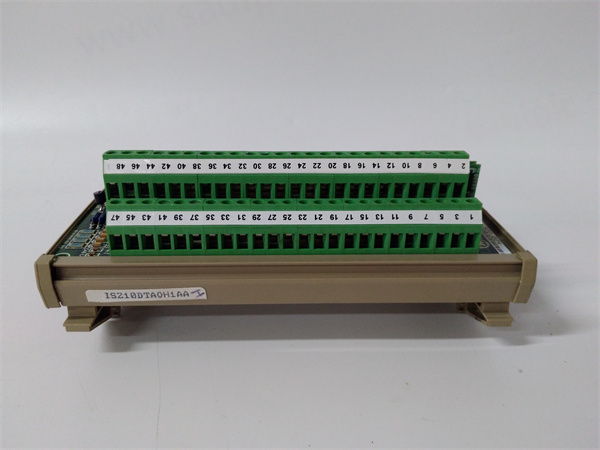

The GE IS200DTAIH1ACC is a highly specialized and crucial component within the industrial automation landscape, designed by the industry – leading GE. As part of the Mark VI series, this board is specifically engineered for applications related to turbine control and protection systems. It serves as a key element in ensuring the safe and efficient operation of turbines in power generation plants, oil and gas refineries, and other industrial facilities where turbines play a vital role.

The IS200DTAIH1ACC functions as a digital input I/O processor. It receives various input signals from sensors and other devices in the turbine system. These signals could include speed sensor data, status signals from valves, and other critical information. By accurately processing these inputs, it can make decisions and send out appropriate control signals. This not only helps in maintaining the optimal performance of the turbine but also provides essential protection functions. For example, in case of an abnormal speed increase or a malfunctioning component, the IS200DTAIH1ACC can trigger emergency shutdown procedures to safeguard the entire turbine system from potential damage. Its high – reliability design and precise signal processing capabilities make it an integral part of modern industrial control setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200DTAIH1ACC |

| Manufacturer | GE |

| Product Type | Digital Input I/O Processor Board |

| Operating Voltage | 220V – 380V |

| Output Frequency | 50/60 Hz |

| Product Certification | CE |

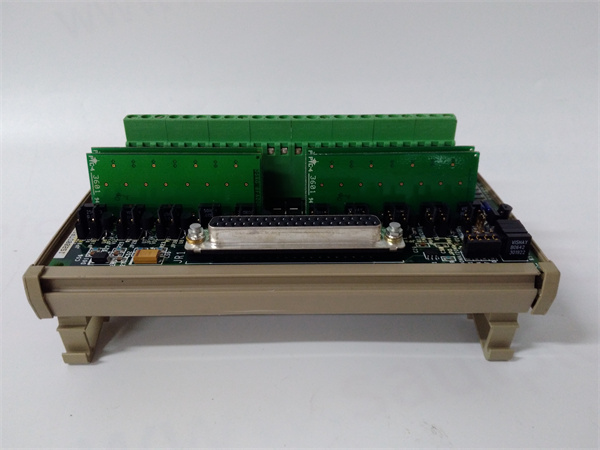

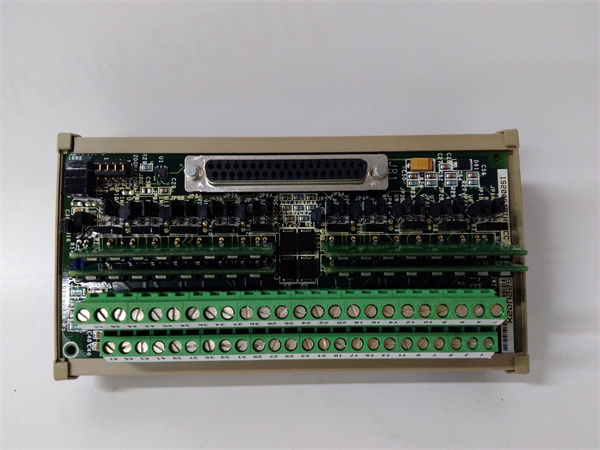

| Communication Interface | Ethernet 10Base2 (for IONet communication in Mark VI system) |

| Input Signal Types | Signals from speed sensors, valve status sensors, etc. |

| Input Voltage Ranges | Compatible with various sensor output voltage levels relevant to turbine systems |

| Isolation Features | Electrical isolation to prevent signal interference |

| Mounting Type | Designed to be installed in 13 or 21 – slot VME card racks (common in Mark VI setups) |

| Dimensions | Compact size suitable for standard industrial rack – mount installations (specific dimensions available in product manual) |

| Weight | Lightweight for easy handling during installation (weight details in product manual) |

IS200DTAIH1ACC

Main Features and Advantages

High – Precision Signal Processing

The IS200DTAIH1ACC is equipped with advanced signal processing algorithms. It can accurately interpret the input signals from multiple sources in the turbine system. For instance, when dealing with speed sensor data, it can precisely calculate the turbine’s rotational speed, ensuring that any deviation from the setpoint is quickly detected. This high – precision processing is essential for maintaining the stable operation of the turbine and preventing performance – degrading issues.

Robust Protection Functions

This board plays a pivotal role in the protection of the turbine. It monitors various critical parameters and, in case of any abnormal conditions, can initiate emergency shutdown procedures. For example, if it detects an overspeed situation beyond the safe limits, it will immediately send signals to shut down the turbine, preventing catastrophic failures. Its ability to handle such protection functions reliably makes it a cornerstone in ensuring the safety of industrial turbine operations.

Seamless Integration with Mark VI System

As part of the Mark VI series, the IS200DTAIH1ACC is designed for seamless integration. It can communicate effectively with other components in the Mark VI system through the Ethernet 10Base2 interface for IONet communication. This allows for coordinated operation within the entire turbine control and monitoring setup. All components can share data and work together in harmony, enhancing the overall efficiency and reliability of the system.

Application Field

Power Generation Plants

In power generation plants, whether they are fueled by coal, natural gas, or other sources, turbines are the heart of the electricity – generation process. The IS200DTAIH1ACC is used to control and protect these turbines. It monitors the speed of the turbine to ensure that the generator produces electricity at the correct frequency. Additionally, it keeps an eye on other parameters such as oil pressure and temperature of critical components. In case of any anomalies, it can quickly take corrective actions, such as adjusting the fuel supply or triggering a shutdown, to prevent damage to the expensive turbine equipment and ensure continuous power supply.

Oil and Gas Refineries

Oil and gas refineries use turbines for various purposes, including powering compressors that transport oil and gas through pipelines. The IS200DTAIH1ACC is deployed to control these turbines. It ensures that the turbines operate at optimal efficiency, which is crucial for the smooth operation of the entire refinery process. By accurately processing input signals from sensors placed throughout the turbine – compressor system, it can adjust the turbine’s performance in real – time, adapting to changes in the refinery’s production requirements.

Industrial Manufacturing Facilities

Some large – scale industrial manufacturing facilities, such as those in the chemical or automotive industries, may use turbines for power generation or for specific manufacturing processes. The IS200DTAIH1ACC is utilized to safeguard and optimize the operation of these turbines. For example, in a chemical plant, if a turbine is used to drive a large – scale mixing or separation process, the board will monitor the turbine’s performance and protect it from any operational issues, ensuring the uninterrupted production of chemical products.

IS200DTAIH1ACC

Related Products

IS200AEADH1ABA

This is also a GE Mark VI board component. While the IS200DTAIH1ACC focuses on digital input I/O processing for turbine control and protection, the IS200AEADH1ABA may have different functions, perhaps related to analog signal handling or a different aspect of system control. It can be used in combination with the IS200DTAIH1ACC in a Mark VI system to provide a more comprehensive control and monitoring solution.

IS200TICIH1ACC

It is an isolated digital input contact voltage sensing board. Similar to the IS200DTAIH1ACC, it is involved in handling digital input – related tasks. However, it may be more specialized in voltage detection from specific sources like fuses, switches, and relay contacts. In some industrial setups, the IS200TICIH1ACC can work alongside the IS200DTAIH1ACC to cover different aspects of digital input processing in a turbine control system.

DS200SDCCG1AFD

A drive control board by GE. It is related to the control of drives in industrial systems. In a turbine – based setup, the DS200SDCCG1AFD may be responsible for controlling the drives that power certain components of the turbine system. The IS200DTAIH1ACC can interact with this board, as it processes input signals related to the overall operation of the turbine, and the drive control board executes the actual control of the drives based on the signals received and processed in the system.

IC600C7RR

As part of GE’s product range, it may be a module with different functionality, perhaps related to general – purpose control or signal conditioning. In an industrial automation system where the IS200DTAIH1ACC is used for turbine – specific control, the IC600C7RR can be used to handle other control tasks or provide additional functionality that complements the operation of the turbine control system.

MP3010

An motor protection relay. In an industrial environment where turbines are driven by motors, the MP3010 can protect the motors from various faults. The IS200DTAIH1ACC can work in tandem with the MP3010. The IS200DTAIH1ACC monitors the overall turbine operation and can trigger actions based on motor – related issues detected, while the MP3010 directly protects the motor from electrical faults such as overloads and short – circuits.

Installation and Maintenance

Pre – installation preparation: Before installing the IS200DTAIH1ACC, it is crucial to ensure that the power supply to the entire system is turned off. Verify that the operating voltage of 220V – 380V is stable and within the specified range for the board. Check the VME card rack where it will be installed (either 13 or 21 – slot as per the Mark VI system requirements) for any signs of damage or debris. Familiarize yourself with the wiring diagrams provided in the product manual to correctly connect the Ethernet 10Base2 communication cable and other necessary input and output wires. Make sure all the sensors and devices that will be connected to the IS200DTAIH1ACC are properly calibrated and in working condition.

Maintenance recommendations: Regularly inspect the IS200DTAIH1ACC for any signs of physical damage, such as cracks on the board or loose connections. Monitor the input and output signals periodically to ensure they are within the expected ranges. Check the communication status with other components in the Mark VI system to guarantee seamless data transfer. If any issues are detected, refer to the troubleshooting guide in the product manual. In case of a software – related problem, ensure that the firmware of the board is up – to – date. If necessary, contact GE’s technical support team for professional assistance in maintaining the optimal performance of the IS200DTAIH1ACC.

Product Guarantee

GE stands firmly behind the quality of the IS200DTAIH1ACC. The board comes with a comprehensive quality assurance program. In the unlikely event of a manufacturing defect, GE offers a reliable after – sales service commitment. Their global network of technical support teams is available around the clock to assist customers. Whether it’s a query regarding installation, operation, or troubleshooting, customers can expect prompt and professional help. GE’s confidence in the IS200DTAIH1ACC is evident in their commitment to ensuring the board functions optimally throughout its lifespan. They also provide regular software updates to enhance the board’s performance and compatibility with evolving industrial systems, giving customers peace of mind when incorporating it into their critical industrial operations.