Description

Detailed Parameter Table

| Parameter name | Parameter value |

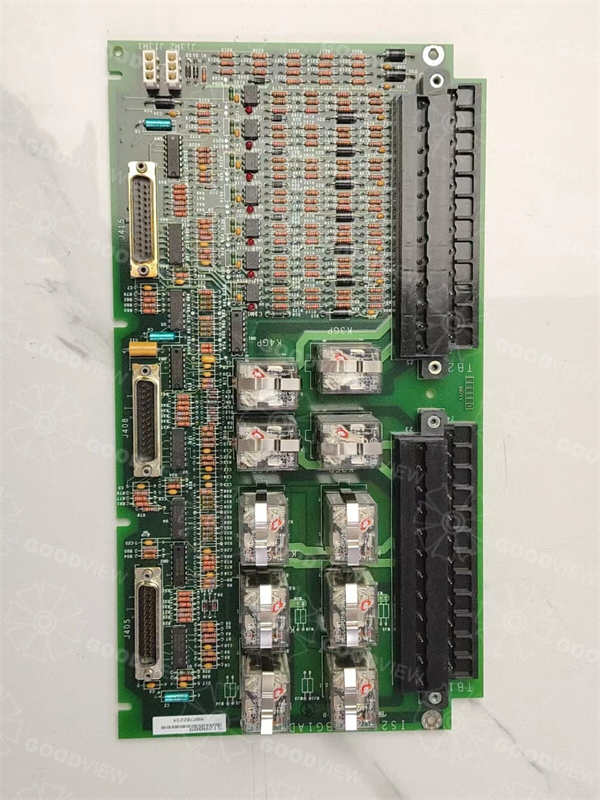

| Product model | IS200ECTBG1ADE |

| Manufacturer | GE |

| Product category | Terminal board module |

| Electrical performance | Operating voltage: 24 VDC; Power consumption: Approximately 5 watts |

| Physical size | Roughly 140 mm x 90 mm x 180 mm |

| Interface type | Multiple terminals for analog (4 – 20 mA, 0 – 10 VDC) and digital (24 VDC) signals |

| Communication protocol | N/A (mainly for signal connection, not a communication – protocol – handling module) |

| Environmental requirements | Operating temperature: – 40°C to +70°C; Storage temperature: – 55°C to +85°C |

| Installation method | DIN rail or screw – mountable |

| Performance indicators | Signal isolation up to 2500 VAC |

GE IS200ECTBG1ADE

Product Introduction

The GE IS200ECTBG1ADE is an exciter contact terminal board module, part of GE’s esteemed Mark VI speedtronic series. It serves as a vital link between field devices and control modules within an industrial automation system. This module is engineered to support both excitation contact inputs and outputs, ensuring seamless data flow. For instance, it can efficiently transmit signals from sensors to the control system and relay control commands to actuators. In the Mark VI system, which is designed for the management of gas, steam, and wind turbine automated drive assemblies, the IS200ECTBG1ADE plays a fundamental role in maintaining system integrity. Its core functions include signal conditioning, connection management, and electrical isolation, all of which are essential for accurate and reliable operation in industrial settings.

Core Advantages and Technical Highlights

Reliable Signal Transmission

The IS200ECTBG1ADE ensures stable and accurate signal transfer. With its high – quality terminals and advanced signal conditioning capabilities, it minimizes signal loss and interference. In industrial environments filled with electromagnetic noise, such as factories with numerous motors and electrical equipment, this module can precisely transmit signals from various sensors to the control system, enabling correct control decisions.

Robust Environmental Adaptability

Featuring an operating temperature range from – 40°C to +70°C, this module can withstand extreme conditions. Whether it’s the sweltering heat of a steel mill or the frigid cold of a northern – hemisphere power plant, the IS200ECTBG1ADE continues to function flawlessly. Its rugged construction also resists vibration and humidity, making it suitable for offshore platforms and mining operations.

Enhanced Electrical Isolation

Equipped with 2500 VAC signal isolation, the module effectively prevents electrical noise and ground loops from affecting signal integrity. In complex industrial power systems where electrical interference is common, this isolation feature is crucial. For example, in a chemical plant with high – voltage power distribution, the IS200ECTBG1ADE can ensure that signals from process sensors remain accurate, preventing false readings and system malfunctions.

Typical Application Scenarios

Power Generation

In power plants, the GE IS200ECTBG1ADE is extensively used. For steam and gas turbines, it connects sensors that monitor parameters like temperature, pressure, and vibration to the control system. By accurately transmitting these signals, it enables operators to monitor the health of the turbines in real – time and make timely adjustments. In a nuclear power plant, the module’s reliability is of utmost importance, as it ensures the proper functioning of sensors that are critical for safe operation.

Manufacturing

In manufacturing automation, the IS200ECTBG1ADE plays a key role. On automated production lines, it interfaces with sensors such as proximity sensors and photoelectric sensors, as well as actuators like solenoid valves and motor starters. It enables the control system to precisely manage the movement of products along the conveyor belt and the operation of robotic arms. In an automotive manufacturing plant, for example, the module helps in ensuring that parts are correctly positioned and assembled.

Water and Wastewater Treatment

In water treatment facilities, the IS200ECTBG1ADE connects level sensors, flow meters, and chemical dosing pumps to the control system. It allows for accurate monitoring and control of water treatment processes. In a municipal wastewater treatment plant, the module ensures that signals from dissolved oxygen sensors are accurately transmitted to the control system, which is essential for optimizing the aeration process and improving treatment efficiency.

GE IS200ECTBG1ADE

Related Model Recommendations

IS200ECTBG1A: Belongs to the same series as the IS200ECTBG1ADE. It has a similar function but may have some differences in specific configurations. It is also used in excitation control systems and can be considered as a related alternative in certain setups.

IS200EGPAG1A: This is an exciter gate pulse amplifier board. It works in tandem with the IS200ECTBG1ADE in the overall excitation control system. The IS200EGPAG1A controls the power bridge and receives gate commands, while the IS200ECTBG1ADE manages the contact inputs and outputs related to the excitation system.

IS200EXTBG1A: An exciter terminal board that is part of the input/output terminal board models. It has a related function to the IS200ECTBG1ADE in supporting contact inputs and signal conditioning circuits. However, it may have different application scenarios, with the IS200ECTBG1ADE being more focused on redundant systems.

IS200ECCBG1BDE: A complementary terminal board module with additional digital I/O channels. When paired with the IS200ECTBG1ADE, it can expand the overall I/O capabilities of the system, especially useful in larger – scale industrial automation projects.

IS200EXHSG3REC: An excitation control module. Although its main function is excitation control, it interacts with the IS200ECTBG1ADE in a complete industrial control system. The IS200ECTBG1ADE may transmit relevant signals to the IS200EXHSG3REC for overall system operation and control.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS200ECTBG1ADE, ensure that the installation environment is clean, dry, and free from excessive dust and moisture. The ambient temperature should be within the specified operating range. Tools required include a screwdriver for mounting the module on the DIN rail or using screw mounts. Disconnect all power sources from the system to avoid electrical hazards during installation. Make sure to follow the wiring diagram provided in the product manual carefully when connecting field devices to the module’s terminals.

Maintenance Suggestions

For daily maintenance, regularly inspect the module for any signs of physical damage, such as cracks or loose components. Check the terminals for corrosion or loose connections. If there are any issues with signal transmission, use diagnostic tools to identify whether the problem lies with the IS200ECTBG1ADE or the connected field devices. In case of a malfunction, refer to the troubleshooting guide in the product manual. For spare parts replacement, only use genuine GE parts to ensure compatibility and performance. Periodically clean the module to prevent dust accumulation, which can affect its heat dissipation and overall performance.

Service and Guarantee Commitment

GE stands firmly behind the quality of the IS200ECTBG1ADE. The product comes with a 12 – month warranty against manufacturing defects. In the unlikely event of a product failure during this period, GE will replace or repair the module free of charge. GE’s global technical support team is available 24/7 to assist customers with installation, commissioning, and troubleshooting. Customers can access comprehensive online resources, including user manuals, technical bulletins, and software updates. For critical applications, GE also offers extended warranty options and on – site service agreements. This demonstrates GE’s confidence in the product’s quality and its commitment to providing excellent customer service, ensuring that customers can rely on the IS200ECTBG1ADE for long – term, trouble – free operation.