Description

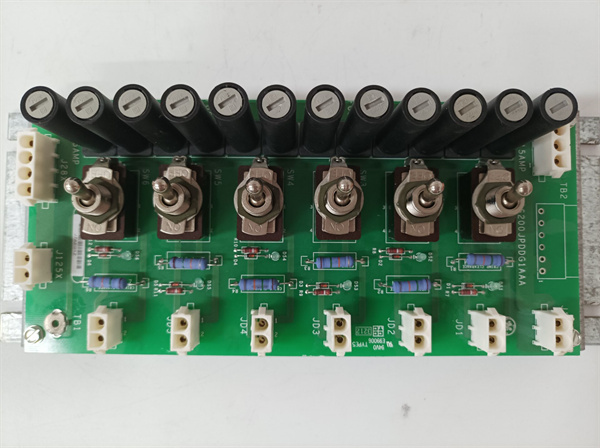

Professional Product Description: GE IS200JPDDG1A Discrete Input/Output Module

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS200JPDDG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Discrete Input/Output Module (Mark V Control System Compatibility) |

| Input Configuration | 16 discrete digital inputs (24V DC, 4mA pull-up) |

| Output Configuration | 8 discrete digital outputs (24V DC, relay, 5A rating) |

| Input Logic | Sinking (negative common) |

| Output Logic | Source (positive common) |

| Input Response Time | 2ms (typical) |

| Output Switching Time | 5ms (make), 3ms (break) |

| Communication Interface | Parallel backplane (GE Mark V proprietary bus) |

| Power Requirements | 24V DC (from Mark V backplane); Current draw: 0.6A typical |

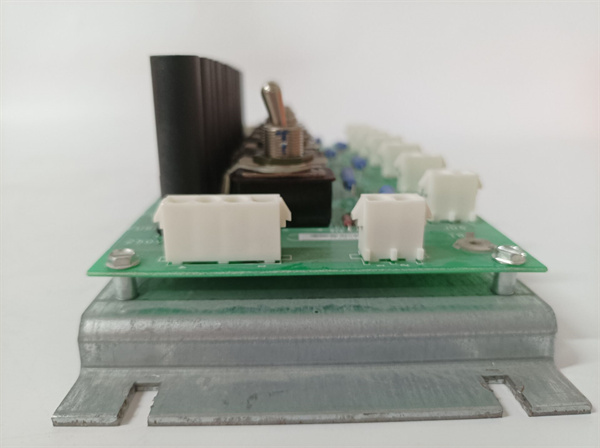

| Physical Dimensions (H×W×D) | 140mm × 100mm × 35mm (rack – mount form factor); Weight: 350g |

| Operating Temperature Range | -10°C to +55°C (ambient); -20°C to +65°C (short – term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Protection Features | Input overvoltage protection (up to 30V DC); Output short – circuit protection |

| Compatibility | GE Mark V Turbine Control Systems; Legacy industrial discrete sensors (limit switches, proximity sensors); Small discrete actuators (solenoid valves, relays) |

GE IS200JPDDG1A

Product introduction

The GE IS200JPDDG1A is a discrete input/output module meticulously designed for seamless integration with GE’s renowned Mark V control systems. Widely deployed in industrial settings, the Mark V control systems have long been the backbone for managing complex machinery operations, especially in power generation, oil and gas, and heavy manufacturing. The GE IS200JPDDG1A module plays a pivotal role in these setups by serving as the vital link between the control system and the real – world discrete devices.

In practical terms, discrete devices such as limit switches, which detect the position of mechanical components, and proximity sensors, which sense the presence of objects, send digital signals to the GE IS200JPDDG1A‘s inputs. For example, in a power plant’s steam turbine system, limit switches on the turbine’s access doors are connected to the module’s inputs. When a door is opened, the corresponding input changes state, and the module relays this information to the Mark V control system. On the output side, the module can activate discrete actuators. In an oil refinery, the module’s relay outputs can switch solenoid valves that control the flow of various chemicals in the refining process.

What sets the GE IS200JPDDG1A apart is its ability to handle a significant number of discrete signals in a compact form factor. With 16 digital inputs and 8 relay outputs, it provides a cost – effective and space – saving solution for industrial facilities that need to interface a large number of discrete devices with their Mark V – based control infrastructure. This makes it an essential component for maintaining the operational integrity of legacy systems, allowing for continued reliable performance without the need for a complete control system overhaul.

Core advantages and technical highlights

High – Density I/O for Compact Installations

The GE IS200JPDDG1A offers a high – density I/O configuration, packing 16 discrete inputs and 8 discrete outputs into a relatively small module. In a manufacturing plant with limited space in its control cabinets, this module can replace multiple smaller I/O modules, reducing the overall footprint by up to 40%. This not only saves valuable cabinet space but also simplifies cabling, as there are fewer modules to wire. The reduced wiring complexity also leads to a decrease in installation time by approximately 30%, as technicians have fewer connections to make.

Robust Relay Outputs for Heavy – Duty Applications

The 8 discrete relay outputs of the GE IS200JPDDG1A are rated at 5A, making them suitable for driving heavy – duty discrete loads. In a wastewater treatment plant, these relay outputs can directly control large solenoid valves that regulate the flow of wastewater. Unlike solid – state outputs, relays can handle inductive loads without the need for additional protection circuitry. The mechanical nature of the relays also provides visual confirmation of the output state through integrated LED indicators. This makes troubleshooting much easier for maintenance technicians, as they can quickly identify whether an output is energized or not, reducing mean – time – to – repair (MTTR) by up to 50% in case of output – related issues.

Fast Input/Output Response for Real – Time Control

With input response times as low as 2ms and output switching times of 5ms (make) and 3ms (break), the GE IS200JPDDG1A is well – equipped for applications that require rapid response to discrete events. In a high – speed packaging line in the food and beverage industry, the module can quickly detect the presence of a product using proximity sensors (connected to its inputs) and activate a solenoid – driven packaging mechanism (connected to its outputs) within milliseconds. This fast response ensures smooth and efficient operation of the packaging line, minimizing product jams and maximizing throughput.

Compatibility with Legacy Mark V Systems

Designed specifically for GE’s Mark V control systems, the GE IS200JPDDG1A can be easily integrated into existing installations without the need for complex hardware or software modifications. In a 1980s – era power generation facility still relying on a Mark V control system, replacing a faulty discrete I/O module with the GE IS200JPDDG1A is a straightforward process. The module uses the same parallel backplane communication protocol as the original module, and its physical dimensions are identical, allowing for a seamless swap. This compatibility saves plants significant costs, as they can avoid the expense of upgrading to a new control system when an I/O module fails.

Typical application scenarios

Power Generation Plants

In a coal – fired power plant, the GE IS200JPDDG1A is used to monitor and control various discrete devices in the boiler and turbine systems. Limit switches on the coal feeder gates are connected to the module’s inputs. When a gate is not fully closed or opened, the input state changes, and the module sends an alarm signal to the Mark V control system. On the output side, the module controls solenoid valves that regulate the flow of cooling water to the turbine bearings. During a startup sequence, the module activates the solenoid valves in a precise order, ensuring proper lubrication and cooling of the bearings, which is crucial for the safe and efficient operation of the turbine.

Oil and Gas Refineries

At an oil refinery, the GE IS200JPDDG1A plays a key role in the distillation process. Proximity sensors that detect the level of crude oil in storage tanks are connected to the module’s inputs. When the oil level reaches a pre – set high or low limit, the module sends signals to the Mark V control system, which can then adjust the flow of crude oil into the distillation units. The module’s relay outputs are used to control the opening and closing of large – scale solenoid valves that direct the flow of refined products such as gasoline, diesel, and jet fuel to different storage tanks or pipelines.

Manufacturing Plants

In an automotive manufacturing plant, the GE IS200JPDDG1A is used in the assembly line. Limit switches on robotic arms detect the position of components during the assembly process. If a component is not in the correct position, the module’s inputs sense the deviation, and the Mark V control system can pause the assembly line to prevent misassembly. The module’s outputs are used to activate pneumatic cylinders that hold and position car parts during welding and painting operations. The fast response time of the module ensures that the assembly line operates smoothly and efficiently, reducing production errors and increasing overall productivity.

Related model recommendations

GE IS200JPDDG2A: An enhanced version of the GE IS200JPDDG1A with 24 discrete inputs and 12 discrete outputs. It is suitable for larger industrial systems that require a higher density of I/O channels.

GE DS200CTBAG1A: A terminal board that can be used in conjunction with the GE IS200JPDDG1A. It provides a convenient way to connect field wires to the module, simplifying wiring and maintenance.

GE DS200CPCAG1A: A 24V DC power conditioning module that can be used to filter noise on the power supply to the GE IS200JPDDG1A. This is especially useful in noisy industrial environments where electrical interference can affect the module’s performance.

GE Mark V Backplane Adapter (IC600BF802): In cases where the Mark V backplane has an older revision, this adapter can be used to ensure compatibility with the GE IS200JPDDG1A.

GE IS400JGPAG1A: An analog input module that can be used in combination with the GE IS200JPDDG1A in applications where both analog and discrete signals need to be processed. For example, in a process control system where temperature (analog) and valve position (discrete) are monitored.

GE IS200JPDDG1A Maintenance Kit: This kit includes spare relays, fuses, and replacement terminal blocks for the GE IS200JPDDG1A. It helps to extend the lifespan of the module and reduces downtime in case of component failures.

GE Mark V Configuration Software (v5.4+): This software is required to configure the GE IS200JPDDG1A within the Mark V control system. It allows technicians to set input and output parameters, assign functions to I/O channels, and monitor the module’s status.

GE Discrete Sensor/Actuator Cable Set: A pre – fabricated cable set that can be used to connect discrete sensors and actuators to the GE IS200JPDDG1A. It ensures proper electrical connections and reduces the risk of wiring errors.

GE IS200JPDDG1A

Installation, commissioning and maintenance instructions

Installation Preparation

Before installing the GE IS200JPDDG1A, it is essential to verify compatibility with the Mark V backplane revision. In case of an older backplane, the GE IC600BF802 adapter may be required. The installation environment should be within the specified temperature range of – 10°C to +55°C and humidity range of 5% – 95% non – condensing. Necessary tools include a torque screwdriver (0.5 – 0.8 N·m), wire strippers suitable for 22 – 14 AWG wires, ESD – safe gloves to prevent electrostatic discharge damage, a precision multimeter for voltage and current measurements, and the Mark V configuration software (v5.4+). Safety is of utmost importance; power off the Mark V system and apply lockout/tagout procedures. Label all existing wiring on the module being replaced to avoid confusion during the installation process.

Installation Process

Align the GE IS200JPDDG1A with the appropriate backplane slot and gently push it in until the connector is fully engaged. Secure the module in place using M4 screws, torquing them to the recommended 0.6 N·m. Connect discrete sensors (such as limit switches and proximity sensors) to the input terminal blocks, ensuring that the wiring follows the correct polarity (negative common for sinking inputs). Similarly, connect discrete actuators (such as solenoid valves and relays) to the output terminal blocks, following the positive common configuration for the relay outputs.

Commissioning

After installation, power on the Mark V system. Use the Mark V configuration software to scan for new modules and configure the GE IS200JPDDG1A. Assign appropriate input and output functions to each channel, such as designating an input channel to monitor a specific limit switch and an output channel to control a particular solenoid valve. Test the inputs by manually actuating the connected sensors and verify that the module’s input status LEDs change accordingly. Similarly, test the outputs by commanding them to switch states from the control system and check that the connected actuators operate as expected.

Maintenance Suggestions

For day – to – day operation, regularly monitor the GE IS200JPDDG1A‘s status LEDs via the Mark V HMI. Green LEDs indicate normal operation, red LEDs signal faults, and amber LEDs show alarms. Check for any abnormal input or output behavior, such as inputs that do not change state when actuated or outputs that fail to switch. Every six months, perform a visual inspection of the module. Check for loose wires in the terminal blocks and retorque them if necessary. Clean the module using a dry, lint – free cloth to remove dust and debris. Once a year, test the relay outputs by applying a known load and verifying that the relays can handle the current without overheating or contact degradation. In case of a fault, use the Mark V diagnostics to isolate the problem. If the issue is with the module, replace it with a GE – approved spare module, as third – party modules may not be fully compatible with the Mark V system.

Service and guarantee commitment

The GE IS200JPDDG1A comes with a 24 – month manufacturer’s warranty from GE. This warranty covers any defects in materials, workmanship, or compatibility with the Mark V control systems. Recognizing the importance of this module in legacy industrial infrastructure, GE offers a “legacy support program” for the GE IS200JPDDG1A. Under this program, replacement modules will be available for at least 10 years beyond the standard product end – of – life, ensuring long – term support for customers.

GE provides technical support during business hours (9 AM – 5 PM local time). Specialists with in – depth knowledge of Mark V systems and the GE IS200JPDDG1A are available via phone or email to assist with installation, configuration, and troubleshooting. Customers also receive free access to the GE IS200JPDDG1A technical manual, which includes detailed installation guides, wiring diagrams, and configuration instructions, for 24 months after purchase. For customers with critical applications, such as power generation and oil and gas production, GE offers optional on – site system audits for a fee. These audits help to assess the performance of the GE IS200JPDDG1A and identify any potential areas for improvement or retrofitting, demonstrating GE’s commitment to maintaining the reliability and performance of legacy industrial control systems.