Description

Professional Product Description: GE IS200PICHG1A Legacy Process Interface Controller Module

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS200PICHG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Legacy Process Interface Controller Module (Mark V Control System Compatibility) |

| I/O Configuration | 8 analog inputs (4–20mA DC); 4 analog outputs (4–20mA DC); 8 discrete digital inputs (24V DC); 4 discrete digital outputs (24V DC, relay) |

| Measurement Accuracy | Analog inputs: ±0.1% of full scale (25°C); Analog outputs: ±0.15% of full scale |

| Resolution | 12-bit (4,096 discrete levels) for analog channels; 1-bit for digital channels |

| Update Rate | 10ms per analog channel; 5ms per digital channel (sequential sampling) |

| Communication Interface | Parallel backplane (GE Mark V proprietary bus); No Ethernet support |

| Power Requirements | 24V DC (from Mark V backplane); Current draw: 0.8A typical, 1.2A peak |

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (rack-mount form factor); Weight: 420g |

| Operating Temperature Range | -20°C to +60°C (ambient); -30°C to +70°C (short-term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Protection Features | Analog input overvoltage protection (up to 30V DC); Digital output short-circuit protection |

| Control Capabilities | Basic PID control loops (up to 4); Manual/auto mode switching; Alarm logic |

| Certifications | CE, UL 508C, IEC 61010-1 |

| Compatibility | GE Mark V Turbine Control Systems; Legacy industrial sensors (pressure, flow); Small actuators (solenoid valves, small motors); GE DS200CTBAG1A (terminal board) |

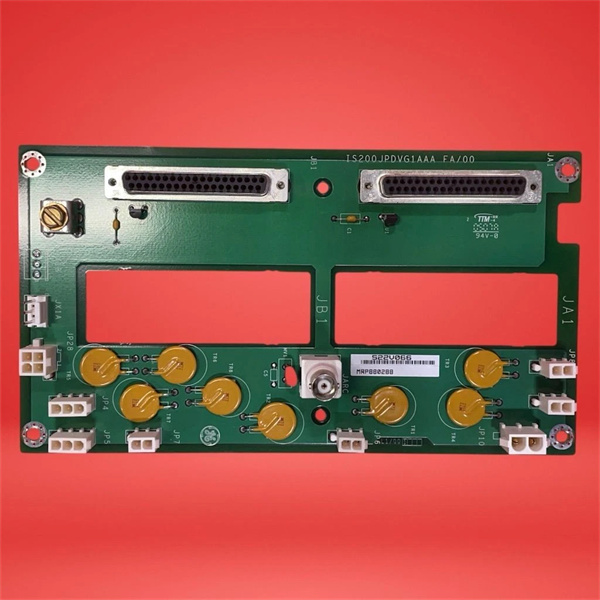

GE IS200JPDVG1A

Product introduction

GE IS200PICHG1A is a legacy process interface controller module engineered exclusively for GE’s Mark V control system, a workhorse in industrial turbine and heavy machinery control for decades. Unlike modern universal I/O modules, GE IS200PICHG1A combines analog and digital I/O with basic PID control capabilities, making it a self-contained “mini-controller” for sub-systems within larger Mark V setups—such as auxiliary pump control, lube oil monitoring, or temperature regulation for turbine accessories.

In legacy industrial operations, GE IS200PICHG1A acts as the critical interface between field devices and the Mark V CPU, handling both data acquisition and localized control. For example, in a 1990s-era gas turbine power plant, GE IS200PICHG1A monitors 6 4–20mA pressure sensors (tracking lube oil pressure, fuel gas pressure) and 2 discrete limit switches (filter clog detectors) via its inputs. Its outputs adjust 3 4–20mA control valves (fuel flow, oil pressure) and activate 1 discrete relay (filter bypass valve)—all while running a simple PID loop to maintain lube oil pressure at 30psi.

What defines GE IS200PICHG1A is its balance of functionality and familiarity: it integrates multiple I/O types in one module (reducing backplane slot usage) and supports basic control logic, eliminating the need for external controllers. This makes it indispensable for facilities still relying on Mark V systems—avoiding the cost and disruption of a full control system upgrade while keeping critical auxiliary processes operational.

Core advantages and technical highlights

All-in-One I/O + Control for Space-Saving Legacy Setups: GE IS200PICHG1A combines analog/digital I/O with PID control in a single module, reducing the number of backplane slots needed in Mark V cabinets by 50% compared to using separate I/O and control modules. In a coal-fired power plant’s turbine auxiliary system, one GE IS200PICHG1A replaces two analog I/O modules and one discrete I/O module—freeing up slots for other critical components. This integration also simplifies wiring, with a single terminal block connecting all sensors and actuators, cutting installation time by 35% for retrofits.

Basic PID Control for Localized Process Stability: Unlike passive I/O modules, GE IS200PICHG1A runs up to 4 independent PID loops, enabling localized control without relying on the Mark V CPU. In a chemical plant’s turbine cooling water system, the module uses a PID loop to maintain water temperature at 45°C: it reads a 4–20mA temperature sensor (input), compares it to the setpoint, and adjusts a 4–20mA control valve (output) to modulate cooling water flow. This local control reduces CPU load and ensures faster response to temperature fluctuations—critical for preventing turbine overheating during CPU busy periods.

Legacy Mark V Compatibility for Seamless Retrofitting: GE IS200PICHG1A is designed to plug directly into Mark V backplanes with no hardware modifications, making it a drop-in replacement for failed legacy modules. In a pulp and paper mill’s steam turbine system, replacing a faulty 1995-era interface module with GE IS200PICHG1A took less than 1 hour—no reconfiguration of the Mark V software was needed, as the module uses the same proprietary communication protocol. This compatibility saves plants $100k+ compared to upgrading to a new control system when legacy modules fail.

Robust Relay Outputs for Heavy-Duty Discrete Control: GE IS200PICHG1A’s 4 discrete relay outputs (24V DC, 5A rating) handle higher current loads than solid-state digital outputs, making them ideal for controlling small motors or solenoid valves. In a wastewater treatment plant’s turbine pump system, the module’s relay outputs activate 3-inch solenoid valves (2A current draw) to divert flow during maintenance—no external relays required. The relays’ mechanical design also provides visual confirmation of output status (via LED indicators), simplifying troubleshooting for technicians familiar with legacy systems.

Typical application scenarios

GE IS200PICHG1A is a cornerstone of a natural gas pipeline compressor station’s turbine auxiliary control system (Mark V). The module monitors 6 analog inputs: 4 pressure sensors (lube oil, fuel gas, discharge pressure) and 2 temperature sensors (bearing temperature) via 4–20mA signals. Its 8 digital inputs track limit switches (filter status, valve position), while 4 analog outputs adjust fuel flow, oil pressure, and cooling water valves. Two digital relay outputs activate a backup pump and an alarm siren.

During a summer heatwave, the turbine’s bearing temperature rose to 55°C (setpoint: 50°C). GE IS200PICHG1A’s PID loop detected the deviation, increased cooling water flow via the analog output, and returned temperature to setpoint in 12 seconds—faster than the Mark V CPU could have responded. When a fuel filter clogged (triggering a digital input), the module activated the backup pump (relay output) and sent an alarm to the Mark V HMI—preventing a compressor shutdown that would have halted gas flow to 10,000 households.

Another common application is a cement plant’s kiln drive turbine system. GE IS200PICHG1A monitors kiln speed (4–20mA from a tachometer) and adjusts a hydraulic valve (analog output) to maintain speed at 3 RPM. Its digital inputs track emergency stop buttons and door interlocks, while a relay output shuts down the kiln feed if speed deviates by ±0.5 RPM. The module’s basic conformal coating withstands the plant’s dusty environment, operating reliably for 5+ years with only annual terminal cleaning.

GE IS200JPDVG1A

Related model recommendations

GE IS200PICHG2A: Enhanced variant of GE IS200PICHG1A (12 analog inputs, 6 analog outputs); upgrade for larger auxiliary systems needing more I/O.

GE DS200CTBAG1A: Entry-level terminal board paired with GE IS200PICHG1A; organizes field wiring for analog/digital signals, simplifying maintenance.

GE DS200CPCAG1A: 24V DC power conditioning module compatible with GE IS200PICHG1A; filters backplane noise to improve analog input accuracy in legacy systems.

GE Mark V Backplane Adapter (IC600BF802): Accessory for GE IS200PICHG1A; ensures compatibility with early Mark V backplane revisions (pre-1993 models).

GE IS400JGPAG1A: Analog input module that complements GE IS200PICHG1A; adds 8 more analog inputs for expanded sensor monitoring in Mark V systems.

GE PID Tuning Tool (PT-MARKV-01): Manual calibration tool for GE IS200PICHG1A; adjusts PID loop parameters (proportional, integral, derivative) for optimal control.

GE DS200DDTBG1A: Discrete I/O terminal board that extends GE IS200PICHG1A; adds 8 digital inputs for monitoring additional limit switches or sensors.

GE Legacy Module Maintenance Kit (MK-IS200): Includes spare relays, trim pots, and conformal coating spray for GE IS200PICHG1A; extends module lifespan in harsh industrial environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IS200PICHG1A, confirm compatibility with the Mark V backplane revision (use GE IC600BF802 adapter if needed). Ensure the environment meets -20°C to +60°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.6–1.0 N·m), wire strippers (22–14 AWG), ESD-safe gloves, precision multimeter, and Mark V configuration software (v5.4+). Safety precautions: Power off the Mark V system and apply lockout/tagout; label existing module wiring to avoid confusion during replacement. Align GE IS200PICHG1A with the backplane slot, engage the connector, and secure with M4 screws. Connect sensors/actuators to terminal blocks (match analog/digital labels to wiring diagram).

Maintenance suggestions: For daily operation, monitor GE IS200PICHG1A’s status LEDs (green = normal, red = fault, amber = alarm) via the Mark V HMI; check PID loop performance (e.g., temperature/pressure stability). Every 6 months, calibrate analog inputs/outputs using a signal generator: inject 4mA/20mA (inputs) and verify readings match ±0.1%; adjust trim pots if needed. Inspect terminal blocks for loose wires (retorque to 0.8 N·m) and clean the module with a dry lint-free cloth (avoid water/chemicals). Test relay outputs annually by activating them manually and verifying load operation. If a fault occurs, use Mark V diagnostics to isolate the issue (e.g., “analog input short on AI3”); replace GE IS200PICHG1A with a GE-approved spare—third-party modules may not communicate with the Mark V bus.

Service and guarantee commitment

GE IS200PICHG1A is backed by a 24-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and compatibility with Mark V systems. Recognizing its role in legacy infrastructure, GE offers a “legacy support program” for GE IS200PICHG1A, ensuring replacement modules are available for 10+ years beyond standard product end-of-life. For priority customers (e.g., power utilities, pipeline operators), GE provides 48-hour shipping of replacement modules to minimize downtime in critical turbine operations.

GE offers technical support for GE IS200PICHG1A during business hours (9 AM–5 PM local time), with specialists experienced in Mark V systems available via phone/email to assist with PID tuning, wiring, and troubleshooting. Customers receive free access to GE IS200PICHG1A’s technical manual (including Mark V configuration guides) for 24 months post-purchase. For enhanced support, GE offers optional on-site legacy system audits (for a fee) to assess GE IS200PICHG1A’s performance and identify potential retrofitting opportunities—reflecting GE’s commitment to extending the value of legacy industrial control systems.