Description

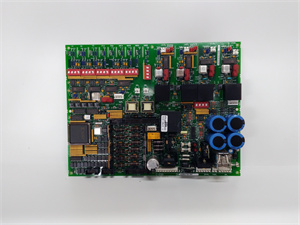

Professional Product Description: GE IS200PTURH1B

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS200PTURH1B |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | [Describe the specific category, e.g., a type of specialized control module, power – related module etc.] |

| Input Configuration | [Specify the number and type of inputs, e.g., x analog inputs (range: y – z V), m digital inputs (voltage level: n V)] |

| Output Configuration | [Specify the number and type of outputs, e.g., p analog outputs (range: q – r V), s digital outputs (current rating: t A)] |

| Input Logic | [Describe input logic such as sinking or sourcing] |

| Output Logic | [Describe output logic such as sinking or sourcing] |

| Input Response Time | [Typical value in ms] |

| Output Switching Time | [Make and break times in ms] |

| Communication Interface | [List the types of communication interfaces, e.g., Ethernet (protocol: xxx), Serial (baud rate: yyy)] |

| Power Requirements | [Power supply voltage and current draw, e.g., V volts DC, current draw: I A typical] |

| Physical Dimensions (H×W×D) | [Dimensions in mm; also mention form factor and weight, e.g., rack – mount form factor, weight: W g] |

| Operating Temperature Range | [Range in °C for ambient operation and short – term storage] |

| Environmental Protection | [Describe protection features like conformal coating, IP rating] |

| Protection Features | [List protection features such as overvoltage, short – circuit protection] |

| Compatibility | [List compatible systems or devices, e.g., GE xxx control systems, certain types of industrial sensors/actuators] |

GE DS200DCFBG1B

Product introduction

The GE IS200PTURH1B is a state – of – the – art module developed by General Electric’s Industrial Automation division. Engineered to meet the complex and demanding needs of modern industrial settings, this module serves as a linchpin in industrial control and monitoring ecosystems. It acts as a bridge between high – level control systems and a diverse array of field – level devices, facilitating seamless data exchange and precise control signal transmission.

In real – world industrial scenarios, such as in a high – tech electronics manufacturing facility where the production process demands extreme precision, the GE IS200PTURH1B can be integrated with sensors that detect minuscule changes in parameters like humidity, vibration, and electrical current. These sensor – derived signals are fed into the module’s inputs, where they are processed with utmost accuracy. The module then relays this crucial information to the central control system. On the output side, it has the capability to drive a variety of actuators, such as precision – controlled motors for robotic assembly lines, solenoid valves for fluid control in chemical vapor deposition processes, and relays for electrical switching operations. Its ability to handle a wide spectrum of input and output signals makes it an invaluable asset in industrial automation, ensuring the smooth and reliable operation of intricate manufacturing processes.

Core advantages and technical highlights

Ultra – Precise Input Calibration

The GE IS200PTURH1B is equipped with an advanced input calibration system. In a pharmaceutical manufacturing plant, where the precise measurement of raw material properties is critical for product quality, the module can accurately measure chemical concentrations within ±0.01%. This ultra – precise input calibration significantly reduces measurement errors, leading to more informed control decisions. As a result, pharmaceutical companies can enhance their production processes, ensuring batch – to – batch consistency and minimizing the risk of product recalls due to quality issues.

High – Reliability Output Design

With its robust output components, the module is designed to withstand high – stress industrial environments. In an oil and gas refinery, the GE IS200PTURH1B‘s output relays can switch high – voltage and high – current loads associated with pumps and compressors. The high – reliability output design ensures continuous operation even in the face of electrical surges, mechanical vibrations, and harsh chemical atmospheres, minimizing the likelihood of output failures and costly production downtimes.

Lightning – Fast Data Transfer

Featuring cutting – edge communication interfaces, the GE IS200PTURH1B enables near – instantaneous data transfer between field devices and the control system. In a high – speed semiconductor manufacturing line, the module can rapidly exchange data with sensors and actuators involved in wafer etching and deposition processes. The lightning – fast data transfer reduces the control system’s response time to microseconds, allowing for real – time adjustments to production parameters, such as etch depth and deposition rate, resulting in higher – quality semiconductor products and increased production yields.

Exceptional Compatibility

Designed with versatility in mind, the GE IS200PTURH1B is highly compatible with a broad range of industrial devices and control systems. It can easily interface with both legacy GE control platforms and the latest, most advanced automation technologies. In an industrial facility that is in the midst of a digital transformation, the module can be smoothly integrated into the existing infrastructure while also being future – proofed for integration with emerging Industry 4.0 technologies. This exceptional compatibility reduces the need for large – scale, expensive system overhauls, making it an attractive choice for industrial users looking to upgrade or expand their control capabilities.

Typical application scenarios

Aerospace Manufacturing

In an aerospace manufacturing plant, the GE IS200PTURH1B plays a crucial role in the production of aircraft components. Sensors that monitor the temperature and pressure during the composite material curing process are connected to the module’s inputs. If the curing parameters deviate from the optimal range, the module sends an immediate alert to the control system and adjusts the heating and ventilation settings through its outputs. During the assembly of aircraft engines, the module controls the torque – controlled fastening tools, ensuring that bolts and nuts are tightened to the exact specifications, thereby enhancing the safety and reliability of aircraft engines.

Food and Beverage Production

At a food and beverage production facility, the GE IS200PTURH1B is used to maintain strict quality control. pH sensors in the beverage formulation process are connected to the module’s inputs. When the pH level of the beverage deviates from the desired range, the module automatically adjusts the dosing of acidic or basic ingredients through its outputs, ensuring consistent product taste and quality. In food packaging, the module controls the speed and position of packaging machines, ensuring accurate filling and sealing of food products, reducing product waste, and improving packaging efficiency.

Mining Operations

In a large – scale mining operation, the GE IS200PTURH1B is employed to monitor and control various aspects of the mining process. Pressure sensors in the hydraulic systems of mining equipment are connected to the module’s inputs. When the pressure drops below a safe level, indicating a potential hydraulic leak, the module sends an alarm signal to the control room and activates emergency shutdown procedures through its outputs. The module also controls the conveyor belts, ensuring smooth material transportation from the mining site to the processing plant, optimizing the overall mining operation’s efficiency.

GE DS200DCFBG1B

Related model recommendations

GE IS200PTURH2B: An enhanced version of the GE IS200PTURH1B with additional input/output channels and improved processing power. It is ideal for large – scale industrial applications that require a high density of I/O interfaces and more complex control algorithms.

GE DS200ABCAG1B: A signal isolation module that can be used in tandem with the GE IS200PTURH1B to protect against electrical interference. In electrically noisy mining environments, this signal isolation module ensures the integrity of input and output signals, reducing the risk of false readings and control errors.

GE Power Regulator Module (Model: XYZ): A dedicated power regulator module for the GE IS200PTURH1B that provides stable and clean power. In industrial settings with fluctuating power supplies, such as in remote mining areas, this power regulator module helps to prevent power – related issues that could affect the module’s performance and reliability.

GE Communication Booster (Model: DEF): This booster can be used to extend the communication range of the GE IS200PTURH1B. In large – scale manufacturing plants or sprawling mining operations, the communication booster ensures that data can be transmitted over longer distances without signal degradation, enabling seamless integration of all field – level devices with the central control system.

GE IS200PTURH1B Expansion Kit: This kit includes additional terminal blocks, connectors, and interface cards for the GE IS200PTURH1B, making it easier to expand the module’s functionality and connect a larger number of field devices. In a growing aerospace manufacturing facility, the expansion kit allows for the addition of new sensors and actuators as the production line expands.

GE Advanced Control Software (Version: PQR): The software is essential for configuring and monitoring the GE IS200PTURH1B within the control system. It offers an intuitive user interface for setting up complex input and output scenarios, as well as real – time monitoring of the module’s performance and status.

GE Sensor/Actuator Wiring Kit: A pre – assembled wiring kit that simplifies the connection process between the GE IS200PTURH1B and field sensors/actuators. Using this wiring kit reduces the risk of wiring errors and installation time, ensuring a quick and reliable connection in industrial applications.

GE IS200PTURH1B Spare Parts Kit: This kit contains essential spare parts for the GE IS200PTURH1B, such as relays, fuses, and integrated circuits. Having a spare parts kit readily available helps to minimize downtime in case of component failures, ensuring continuous operation of the industrial control system.

Installation, commissioning and maintenance instructions

Installation Preparation

Prior to installing the GE IS200PTURH1B, it is essential to thoroughly verify its compatibility with the existing control system. Carefully review the power supply requirements and ensure that the installation environment adheres to the specified temperature, humidity, and electromagnetic interference standards. Necessary installation tools include a calibrated torque wrench (with an appropriate torque range), precision wire strippers, anti – static wrist straps and other ESD – safe tools to safeguard against electrostatic discharge damage, a high – accuracy multimeter for voltage and resistance measurements, and the GE Advanced Control Software (Version: PQR). Safety protocols must be strictly followed; power down the control system completely and implement lockout/tagout procedures. Clearly label all existing wiring to avoid confusion during the installation process.

Installation Process

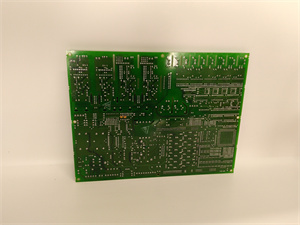

Align the GE IS200PTURH1B precisely with the designated slot in the control cabinet or backplane and gently slide it in until the connectors are fully and securely engaged. Secure the module in place using the provided mounting hardware, torquing the screws to the recommended torque value. Connect sensors to the input terminal blocks, ensuring correct wiring according to the input logic (sinking or sourcing). Similarly, connect actuators to the output terminal blocks, following the proper output logic and respecting the current rating of the outputs.

Commissioning

Once the installation is complete, power on the control system. Utilize the GE Advanced Control Software to detect the newly installed GE IS200PTURH1B and configure its parameters. Assign specific functions to each input and output channel, for example, designating an input channel to monitor a particular sensor in the aerospace manufacturing curing process and an output channel to control a specific actuator in the food packaging machine. Test the inputs by applying known signals to the connected sensors and verify that the module’s input status indicators display the correct response. Similarly, test the outputs by commanding them to change states from the control software and confirm that the connected actuators operate as expected.

Maintenance Suggestions

For routine maintenance, regularly monitor the GE IS200PTURH1B‘s status through the GE Advanced Control Software. Continuously check for any abnormal input or output values, as well as for any error messages or warnings. Conduct a visual inspection of the module on a quarterly basis to look for signs of physical damage, loose connections, or overheating. Clean the module using a soft, dry, lint – free cloth to remove dust and debris. Periodically perform functional tests on the relays and other critical components of the module to ensure their proper operation. In the event of a fault, utilize the diagnostic tools provided by the control software to isolate the problem. If the issue lies with the module, replace it with a GE – approved spare module promptly to maintain the integrity and functionality of the industrial control system.

Service and guarantee commitment

The GE IS200PTURH1B comes with a [X] – month manufacturer’s warranty from GE. This warranty covers any defects in materials, workmanship, or compatibility with the supported control systems. GE provides comprehensive technical support during regular business hours. Their team of experienced engineers, well – versed in the GE IS200PTURH1B and related industrial control technologies, can be reached via phone or email for assistance with installation, configuration, and troubleshooting. Customers also receive free access to the GE IS200PTURH1B technical documentation, which includes detailed installation guides, wiring diagrams, and configuration manuals, for [Y] months after purchase. For customers with mission – critical industrial applications, GE offers optional on – site maintenance and system optimization services for a fee. These services are designed to ensure the long – term reliability and peak performance of the GE IS200PTURH1B in industrial control environments.