Description

Detailed Parameter Table

**

| Parameter name | Parameter value |

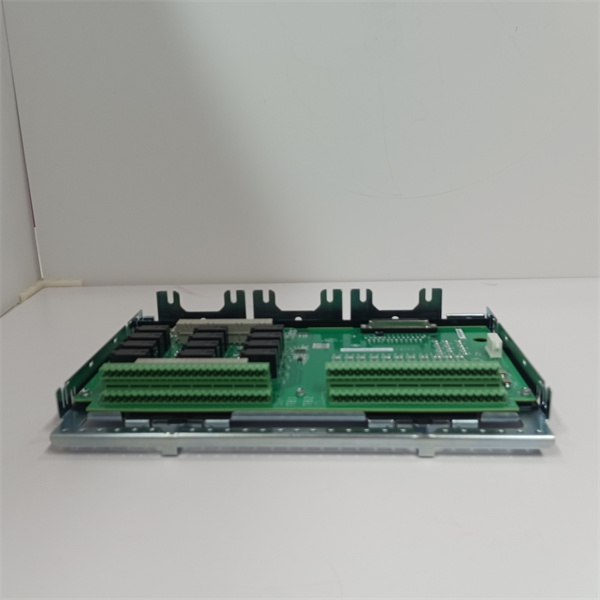

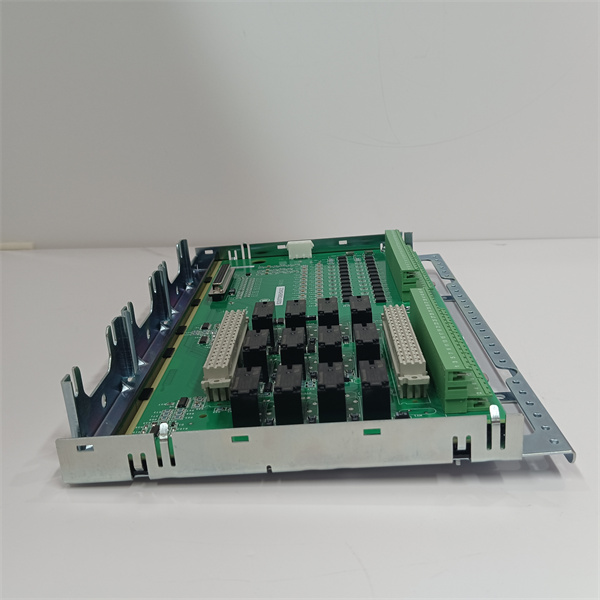

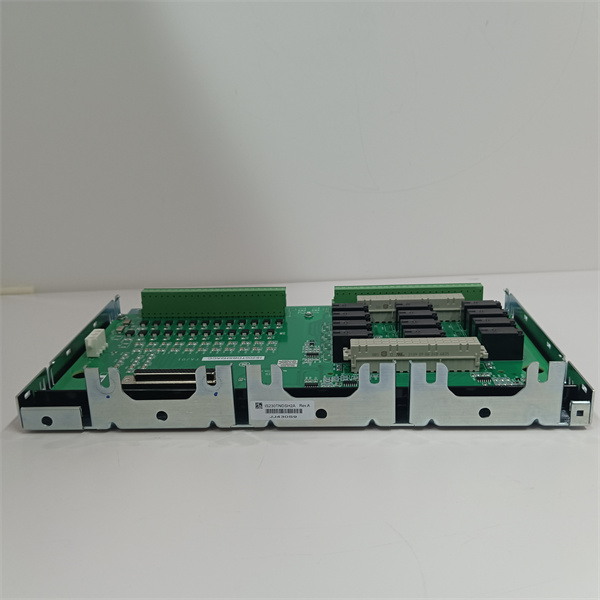

| Product model | IS200TDBSH2ACC |

| Manufacturer | GE (General Electric) |

| Product category | PDIO Terminal Board |

| Compatible with | Discrete I/O packs such as IS220PDIOH1A and IS220PDIOH1B |

| Connectors | DC – 37 pin connector (1) |

| Dimensions | Approximately 16 cm x 16 cm x 12 cm |

| Weight | 0.8 kg |

| Mounting method | Can be mounted in systems according to the requirements of the overall control setup |

| Operating temperature range | Designed to operate in typical industrial temperature ranges, though specific range details may be in the official manual |

| Storage temperature range | Capable of being stored within a wide temperature range suitable for industrial storage conditions, with details in the official documentation |

| Relative humidity | Can withstand relative humidity levels common in industrial environments, with exact values in the product manual |

| Warranty | Warranty details are subject to GE’s standard policies, usually providing a certain period of protection against manufacturing defects |

GE IS200TDBSH2ACC

Product Introduction

The GE IS200TDBSH2ACC is a pivotal PDIO (Process Digital Input/Output) terminal board within General Electric’s industrial control product portfolio. Engineered with precision, this board serves as a crucial interface for connecting and managing digital input and output signals in industrial control systems. It plays a significant role in ensuring seamless communication between various components of a control system, facilitating the accurate transfer of data and commands.

Core Advantages and Technical Highlights

High – compatibility interface: The IS200TDBSH2ACC is designed to be highly compatible with multiple discrete I/O packs, such as the IS220PDIOH1A and IS220PDIOH1B. This compatibility allows for easy integration into different industrial control setups, whether they are part of a large – scale manufacturing plant or a smaller, more specialized industrial process. It enables users to mix and match components based on their specific control requirements, without having to worry about compatibility issues. For example, in a factory that needs to upgrade its existing control system, the IS200TDBSH2ACC can be easily incorporated to work with the existing I/O packs, reducing the cost and complexity of the upgrade process.

Reliable signal transfer: With its well – designed circuitry and high – quality connectors, the board ensures reliable transfer of digital signals. The single DC – 37 pin connector is engineered to provide a stable connection, minimizing the risk of signal loss or interference. In industrial environments where electrical noise and vibrations are common, this reliable signal transfer is essential. For instance, in a power generation plant, the IS200TDBSH2ACC can accurately transmit control signals to various actuators, ensuring the proper operation of turbines and generators, even in the presence of significant electrical interference.

Efficient terminal board design: The board’s design is optimized for efficient use of space and ease of installation. Its compact dimensions of approximately 16 cm x 16 cm x 12 cm make it suitable for installation in control cabinets with limited space. Additionally, the mounting method is flexible, allowing it to be installed in a way that best suits the overall layout of the control system. This efficient design not only simplifies the installation process but also helps in organizing the control system components, making maintenance and troubleshooting easier.

Typical Application Scenarios

Industrial automation systems: In industrial automation setups, the IS200TDBSH2ACC is used to connect digital sensors and actuators to the main control system. It can receive digital input signals from sensors such as proximity sensors, limit switches, and photoelectric sensors, and transmit control signals to actuators like solenoid valves, motor starters, and relays. In a food and beverage production line, for example, the board can be used to control the operation of conveyor belts, filling machines, and packaging equipment. It ensures that the production process runs smoothly by accurately transferring signals between the sensors that detect product position and the actuators that control the movement and operation of the equipment.

Power generation and distribution control: In power generation plants, the IS200TDBSH2ACC plays a vital role in controlling and monitoring the power generation process. It can be used to connect various control devices to the power plant’s distributed control system (DCS). For example, it can transmit signals from sensors that monitor the temperature, pressure, and speed of turbines to the DCS, and receive control signals from the DCS to adjust the operation of valves, pumps, and other equipment. In power distribution networks, the board can be used to control circuit breakers, switches, and other power – related devices, ensuring the stable and reliable distribution of electricity.

Oil and gas production facilities: In the oil and gas industry, the IS200TDBSH2ACC is used in control systems for oil rigs, refineries, and pipelines. It can connect sensors that monitor parameters such as oil flow rate, gas pressure, and temperature to the control system, and transmit control signals to actuators that adjust the operation of valves, compressors, and pumps. In an oil refinery, for instance, the board can be used to control the flow of crude oil through the refining process, ensuring that the refinery operates efficiently and safely.

GE IS200TDBSH2ACC

Related Model Recommendations

GE IS220PDIOH1A: This discrete I/O pack is highly compatible with the IS200TDBSH2ACC. The IS220PDIOH1A can be used in combination with the IS200TDBSH2ACC to form a complete discrete I/O solution. While the IS200TDBSH2ACC serves as the terminal board for connecting signals, the IS220PDIOH1A can handle the actual input and output functions. In an industrial control system, the IS220PDIOH1A can receive digital input signals from sensors and send control signals to actuators, with the IS200TDBSH2ACC ensuring seamless communication between the two components and the rest of the control system.

GE IS200TBAIH2C: The IS200TBAIH2C is an analog input terminal board. In some complex industrial control applications, the IS200TDBSH2ACC can work in tandem with the IS200TBAIH2C. The IS200TDBSH2ACC can handle digital input and output signals, while the IS200TBAIH2C can handle analog input signals. For example, in a chemical plant control system, the IS200TBAIH2C can receive analog signals from sensors that measure chemical concentrations, and the IS200TDBSH2ACC can control digital actuators based on the processed data from both analog and digital inputs.

GE IS200TBCIH2CAA: This is a DCS (Distributed Control System) PLC (Programmable Logic Controller) module. The IS200TDBSH2ACC can communicate with the IS200TBCIH2CAA in a control system. The IS200TBCIH2CAA can perform control logic and data processing functions, and the IS200TDBSH2ACC can provide the interface for connecting input and output devices to the IS200TBCIH2CAA. In an industrial automation system, the IS200TBCIH2CAA can send control commands to the IS200TDBSH2ACC, which then transmits the signals to the appropriate actuators, and receive feedback signals from sensors through the IS200TDBSH2ACC for further processing.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200TDBSH2ACC, ensure that the power to the control system is turned off. Use anti – static precautions, such as wearing anti – static wristbands, to prevent electrostatic discharge (ESD) damage to the board. Check that the physical dimensions of the installation location are compatible with the board’s size. Verify that the connectors on the board and the mating connectors in the control system are clean and free of debris. Ensure that the power supply and grounding in the system are properly configured to meet the requirements of the board.

Commissioning: Once installed, power on the system. Use the appropriate software or control interface to configure the board’s settings, such as input/output signal mapping and communication protocols. Test each input and output channel by connecting known sensors and actuators and verifying that the signals are correctly transmitted and received. Check for any error messages or abnormal behavior during the testing phase. Monitor the communication between the board and other components in the control system to ensure seamless data transfer.

Maintenance suggestions: Regularly perform visual inspections of the IS200TDBSH2ACC for any signs of physical damage, such as bent pins, cracks in the circuit board, or discolored components. Check for loose connections on the connectors. Monitor the operating temperature and humidity of the environment where the board is installed, ensuring they remain within the specified ranges. If any input or output channels fail to operate correctly, use diagnostic tools to check for electrical faults, such as short – circuits or open – circuits. Replace the board if any irreparable damage is detected. Follow GE’s recommended maintenance schedule and procedures for optimal performance.

Service and Guarantee Commitment

GE provides a warranty for the IS200TDBSH2ACC, the details of which are in line with their standard product warranty policies. This warranty typically covers manufacturing defects and component failures under normal operating conditions. Technical support is available through GE’s customer service channels, where trained technicians can assist with installation, troubleshooting, and any other technical issues related to the board. Customers can access product documentation, including installation manuals, technical specifications, and maintenance guides, through GE’s official website. In the event of a warranty claim, GE will work to provide a prompt resolution, either through repair or replacement of the faulty board, to minimize downtime for the customer’s operations.