Description

Detailed Parameter Table

| Parameter name | Parameter value |

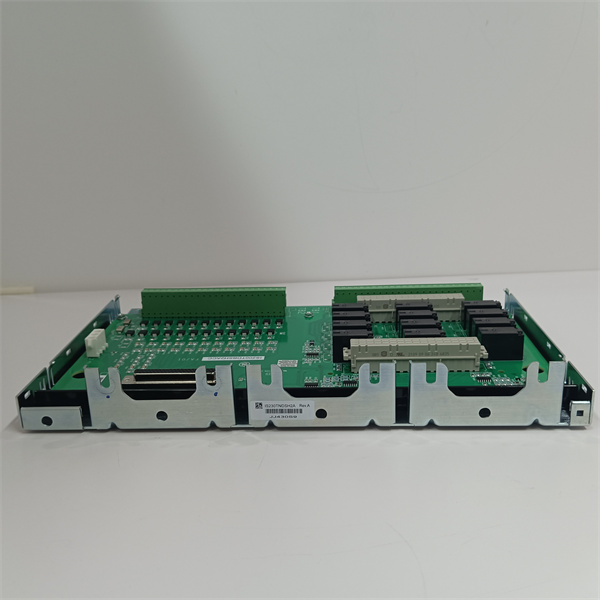

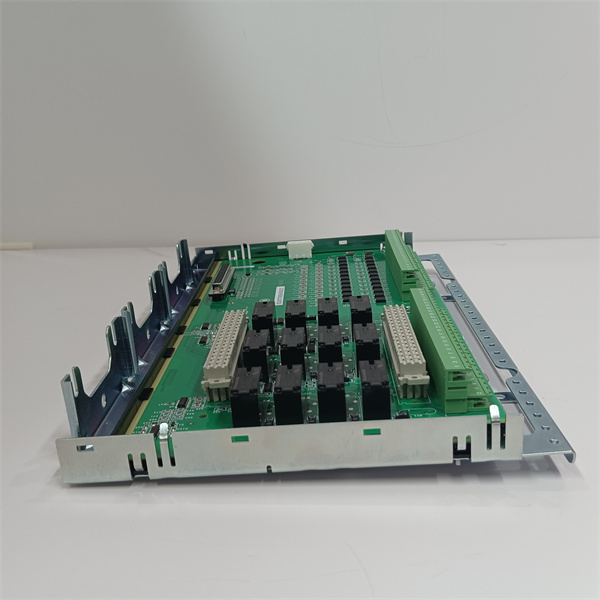

| Product model | IS200TDBSH2ACC |

| Manufacturer | GE (General Electric) |

| Product category | Discrete I/O Terminal Board, part of Mark VI Control System |

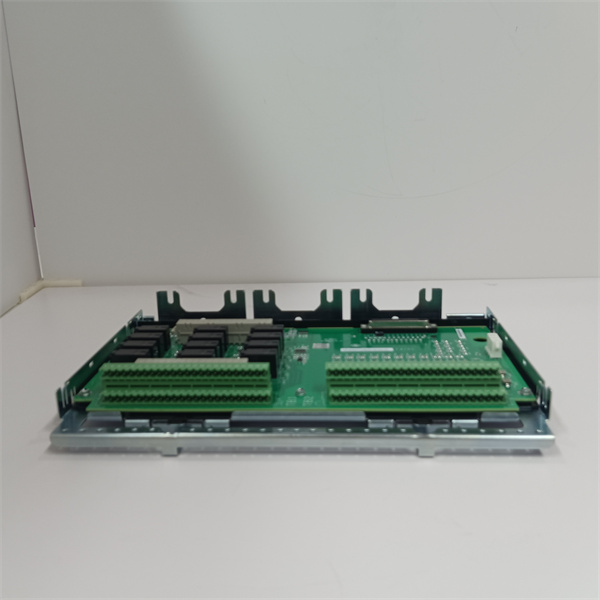

| I/O Channels | 24 digital input channels, 12 relay output channels |

| Input Voltage | 24 VDC for digital inputs |

| Output Rating | Relays rated up to 5 A @ 250 VAC / 30 VDC |

| Isolation | Channel-to-channel isolation for enhanced noise immunity |

| Interface | Compatible with Mark VI backplane connectors |

| Mounting | DIN rail or rack mounting for control cabinet integration |

| Operating Temperature | -10°C to +55°C, suitable for industrial environments |

| Power Requirements | 24 VDC auxiliary power, low power consumption |

| Protection | Overcurrent protection on output channels |

| Certification | Complies with industrial safety standards (e.g., UL, CE) |

GE IS200TDBSH2ACC

Product Introduction

GE’s IS200TDBSH2ACC is a high-performance discrete I/O terminal board, a key component within the Mark VI control system family—renowned for its reliability in critical industrial applications. This board serves as a robust interface between field devices and the control system, bridging sensors, switches, and actuators with the central controller.

The IS200TDBSH2ACC combines 24 digital input channels for monitoring field signals (such as limit switch statuses or equipment alarms) with 12 relay outputs for controlling external devices (including motors, valves, and indicators). Its design ensures seamless integration into Mark VI architectures, making it indispensable for industrial automation, power generation, and process control systems where precise signal management is critical.

Core Advantages and Technical Highlights

Enhanced signal integrity: With channel-to-channel isolation, the IS200TDBSH2ACC minimizes cross-talk and electromagnetic interference (EMI), ensuring accurate signal transmission even in electrically noisy environments like power plants. This isolation prevents ground loops and protects sensitive control system components from voltage spikes.

Robust output protection: Each relay output on the IS200TDBSH2ACC features overcurrent protection, safeguarding both the board and connected devices from damage during short circuits or overloads. In manufacturing lines, this prevents costly downtime caused by electrical faults in conveyor motors or hydraulic valves.

Flexible integration: Designed for DIN rail or rack mounting, the IS200TDBSH2ACC fits easily into standard control cabinets, simplifying system design. Its compatibility with Mark VI backplanes allows plug-and-play integration, reducing installation time and ensuring consistency across multi-module setups.

Industrial-grade durability: Rated for operation in -10°C to +55°C, the IS200TDBSH2ACC thrives in harsh conditions, from freezing outdoor enclosures to hot factory floors. Its rugged construction resists vibration and dust, maintaining performance in heavy machinery environments like steel mills or refineries.

Typical Application Scenarios

In gas turbine power plants, the IS200TDBSH2ACC monitors critical safety interlocks—such as flame detector signals and pressure switch statuses—via its digital inputs. Its relay outputs trigger shutdown mechanisms or alarm systems when anomalies are detected, ensuring compliance with safety protocols. For example, if a high-temperature sensor trips, the board sends a signal to close fuel valves, preventing turbine damage.

In automotive assembly lines, the IS200TDBSH2ACC coordinates robotic workcells: input channels track part presence sensors, while outputs control gripper actuators and conveyor diverters. This real-time signal management ensures precise synchronization of assembly steps, reducing errors in component fitting.

In water treatment facilities, the board manages pump stations: digital inputs monitor flow meter pulses and tank level switches, while relay outputs activate pump motors and valve actuators. The IS200TDBSH2ACC integrates with SCADA systems to automate filtration cycles, optimizing water treatment efficiency and reducing manual intervention.

GE IS200TDBSH2ACC

Related Model Recommendations

IS230TDBSH2A: A simplex discrete I/O terminal board in the same family, with similar channel counts but optimized for smaller-scale applications. It pairs well with the IS200TDBSH2ACC in distributed control setups, handling auxiliary I/O in remote pump stations.

IS200TNDSH2A: A discrete signal module that complements the IS200TDBSH2ACC in Mark VI systems. While the IS200TDBSH2ACC focuses on terminal connections, the IS200TNDSH2A processes signals for higher-level control, creating a complete I/O processing chain.

IS200WDPSH1A: A digital power supply module designed to power the IS200TDBSH2ACC and other Mark VI components. It provides stable 24 VDC, ensuring consistent performance in areas with fluctuating mains power.

IS200AEPAH1BKE: An analog input module that works alongside the IS200TDBSH2ACC in mixed-signal systems. It handles temperature or pressure sensor data, while the IS200TDBSH2ACC manages discrete signals, enabling comprehensive process monitoring.

IS215WEPAH2BB: An analog output module for applications requiring both discrete and analog control. Paired with the IS200TDBSH2ACC, it controls variable-speed drives or proportional valves, expanding system capabilities.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the IS200TDBSH2ACC on a clean DIN rail or rack in a dust-free control cabinet. Ensure the ambient temperature stays within -10°C to +55°C and verify the 24 VDC power supply meets polarity requirements. Use shielded cables for field connections to minimize EMI, and torque terminal screws to 0.5 Nm (per GE specifications) to prevent loose connections.

Maintenance suggestions: Inspect the IS200TDBSH2ACC quarterly for dust buildup, cleaning with compressed air if needed. Test relay outputs annually using a multimeter to check contact resistance—replace relays if values exceed 100 mΩ. Monitor input voltage levels to ensure they stay within 24 VDC ±10%; fluctuations outside this range may cause false signals. For fault diagnosis, use Mark VI diagnostic software to isolate faulty channels without disrupting the entire system.

Service and Guarantee Commitment

GE backs the IS200TDBSH2ACC with a 2-year warranty, covering manufacturing defects and performance issues. Their global technical support team provides 24/7 assistance via online portals and email, offering wiring diagrams, firmware updates, and troubleshooting guides. For critical installations, GE engineers can conduct on-site commissioning to verify I/O functionality and optimize signal routing.

Extended warranty options (up to 5 years) and preventive maintenance contracts are available, including periodic calibration checks. This commitment ensures the IS200TDBSH2ACC delivers reliable performance throughout its lifecycle, maximizing industrial system uptime and minimizing total cost of ownership.