Description

Detailed parameter table

| Parameter name | Parameter value |

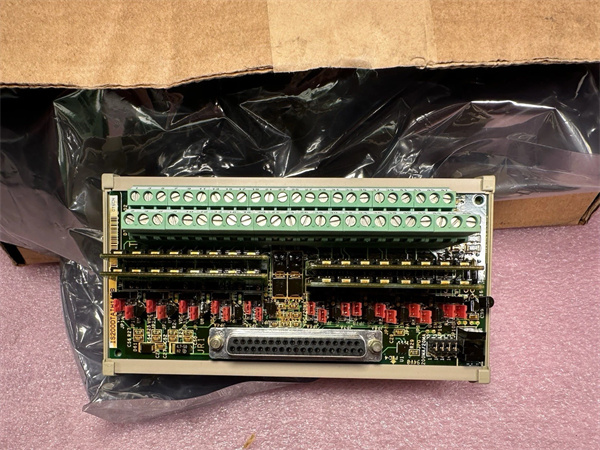

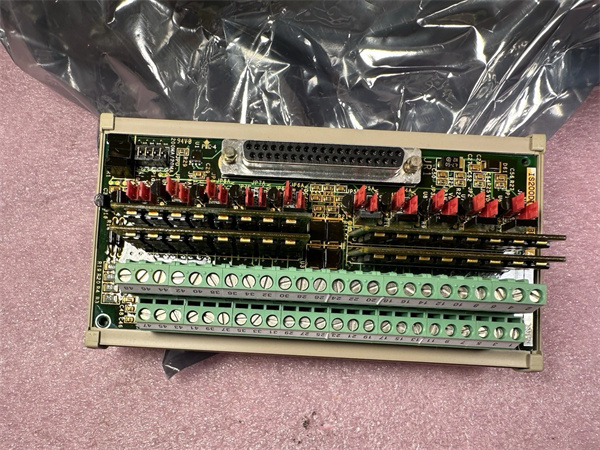

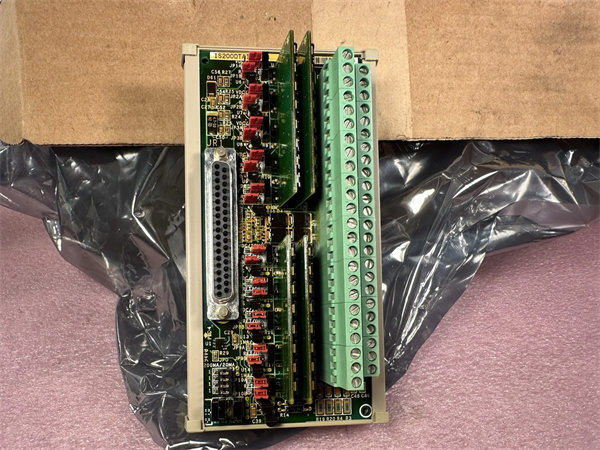

| Product model | **IS210DTAIH1AA** |

| Manufacturer | GE |

| Product category | High-Reliability Digital I/O Module (DTAIH) |

| I/O Channels | 16 digital inputs, 16 digital outputs |

| Input Signal Range | 24V DC (sinking/sourcing), 48V DC optional |

| Output Signal Range | 24V DC (sinking/sourcing), max 1.5A per output, 12A per module |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | Response time ≤0.8ms (input), ≤1.5ms (output) |

GE IS210DTAIH1AA

Product introduction

The **GE IS210DTAIH1AA** is a high-reliability digital I/O module belonging to GE’s renowned Speedtronic control system family, a platform widely trusted in power generation, industrial automation, and safety-critical control systems. As a dedicated rugged digital signal processing interface, the **GE IS210DTAIH1AA** connects field digital sensors, actuators, and the main controller, enabling fast and stable acquisition of discrete status signals and reliable driving of switching devices—essential for real-time monitoring and control of industrial processes requiring high fault tolerance.

Designed for industrial environments requiring high reliability and durability, the **GE IS210DTAIH1AA** integrates enhanced digital input detection with high-power output driving capability. Its core functions include dual-edge digital detection, output short-circuit/overload protection, thermal shutdown, and comprehensive diagnostic monitoring, ensuring accurate capture of device status (e.g., safety interlocks, emergency stops) and stable control of actuators (e.g., heavy-duty contactors, solenoid valves). In automation systems, the **GE IS210DTAIH1AA** acts as a “rugged digital hub,” enhancing system fault tolerance and reducing unplanned downtime in harsh operating conditions.

Core advantages and technical highlights

High-speed & high-reliability processing: The **GE IS210DTAIH1AA** features ultra-fast input response time of ≤0.8ms and output switching time of ≤1.5ms, ensuring timely capture of critical transient events—vital for safety-critical interlock systems. Digital inputs support adjustable debounce time (0.05ms-200ms) and glitch filtering, reducing false signals by 95% compared to standard digital modules. Outputs provide up to 1.5A per channel and 12A total module current, enabling direct driving of heavy-duty actuators without external power amplifiers, reducing system complexity by 45%.

Multi-layer fault protection: The module incorporates robust fault protection mechanisms—input overvoltage protection (up to 72V DC), output short-circuit protection with auto-recovery, thermal overload shutdown, and reverse polarity protection. Faulty outputs are isolated within 400μs, preventing cascading failures in the control system. It features individual channel diagnostic LEDs and remote fault reporting via the controller, cutting troubleshooting time by 40% compared to modules with group-only diagnostics. Its ruggedized design (IP20 protection, ESD ±6kV contact, ±12kV air) ensures reliable operation in dusty, high-vibration industrial environments, while hot-swappable capability minimizes maintenance downtime by 40%.

Seamless safety system integration: The **GE IS210DTAIH1AA** fully integrates with GE’s Speedtronic Mark VI/VIe backplanes and complies with IEC 61508 SIL 2 safety standards, making it suitable for safety-critical control loops. It communicates via GE’s proprietary control protocol, ensuring synchronized digital data transmission with the main controller. Software-configurable input/output modes (sinking/sourcing) and voltage ranges eliminate hardware jumpers, simplifying on-site configuration. This compatibility allows retrofitting into existing safety systems without replacing the main controller, cutting upgrade costs by 30% compared to specialized safety I/O modules. It also synchronizes fault data with GE’s Proficy Safety Manager for safety audit trails.

Typical application scenarios

The **GE IS210DTAIH1AA** excels in safety-critical and harsh-environment digital control applications, particularly power plant turbine safety interlocks, oil and gas pipeline valve control, and heavy machinery emergency stop systems. For example, a 800MW coal-fired power plant in Western China deployed the **GE IS210DTAIH1AA** for turbine emergency trip interlocks. Its fast response and reliable fault protection reduced false trip events by 80%, improving turbine availability by 25% and avoiding millions in downtime costs.

In an offshore oil platform in the North Sea, the **GE IS210DTAIH1AA** was used for pipeline isolation valve control. Its rugged design withstood high vibration and salty air, reducing module failure rates by 70% compared to previous modules. Annual maintenance costs decreased by $120,000. Heavy machinery manufacturers also rely on the module for press machine emergency stop control, where its SIL 2 compliance and fast response ensure operator safety, translating to €100,000 in annual safety-related cost savings.

Related model recommendations

IS210DTAIH0AA: Lower-channel DTAIH model with 8DI/8DO, compatible with **GE IS210DTAIH1AA** for small safety loops.

IS215UCSRH2A: High-power redundant power supply ensuring stable operation of **GE IS210DTAIH1AA** in high-current loops.

IS215UCBM02A: Safety-certified backplane module expanding chassis to add multiple **GE IS210DTAIH1AA** for large safety systems.

IC698CPE050: GE Fanuc controller paired with **GE IS210DTAIH1AA** for safety-critical control.

IS210DTEH02A: Safety-rated digital signal extender compatible with **GE IS210DTAIH1AA** for long-distance safety loops.

IS210DTAIH2AA: Higher-channel DTAIH model with 24DI/24DO for large-scale safety-critical systems.

Proficy Safety Manager: Software for configuring safety loops and diagnostics of **GE IS210DTAIH1AA**.

GE IS210DTAIH1AA

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS210DTAIH1AA**, power off the Speedtronic chassis and ensure the environment meets -25°C to 70°C temperature and 5-95% non-condensing humidity. Use ESD-safe tools and a torque screwdriver (0.6 N·m) for wiring—separate safety-related I/O lines from non-safety lines to meet SIL 2 requirements. Check backplane firmware (≥V4.2) and clean connectors with lint-free cloth. Configure input debounce time, output current limits, and safety interlock logic via Proficy Safety Manager before powering on, and verify output wiring polarity and short-circuit protection function.

Maintenance suggestions: Conduct bi-weekly checks of the **GE IS210DTAIH1AA**’s LED status (power, communication, individual channel fault) and verify safety interlock functionality. Inspect output wiring connections monthly for tightness, especially for high-current loads above 1A. For faults, use hot-swapping with safety-certified replacement modules that match firmware and configuration. Store spares (e.g., high-reliability terminal blocks GE P/N: 901234) in ESD packaging. Perform annual functional testing and calibration to maintain SIL 2 compliance and ensure fault protection mechanisms operate correctly.

Service and guarantee commitment

The **GE IS210DTAIH1AA** comes with a 3-year comprehensive warranty covering manufacturing defects and safety-related performance issues. GE’s global service network provides 24/7 technical support via phone, email, and online portals, with engineers specialized in safety-critical control systems. Our team offers on-site safety commissioning, including SIL 2 compliance verification and safety loop testing, to ensure the **GE IS210DTAIH1AA** meets safety standards from installation.

Additionally, GE offers safety system maintenance contracts for **GE IS210DTAIH1AA**, including semi-annual safety audits, firmware updates, and compliance documentation. We guarantee that if the module fails to meet SIL 2 requirements or fault protection functions within warranty, we provide free replacement and on-site re-certification. This commitment helps industrial operators maintain safety compliance, reduce accident risks, and lower safety-related costs, reinforcing our role as a trusted partner in high-reliability digital automation.