Description

Detailed parameter table

| Parameter name | Parameter value |

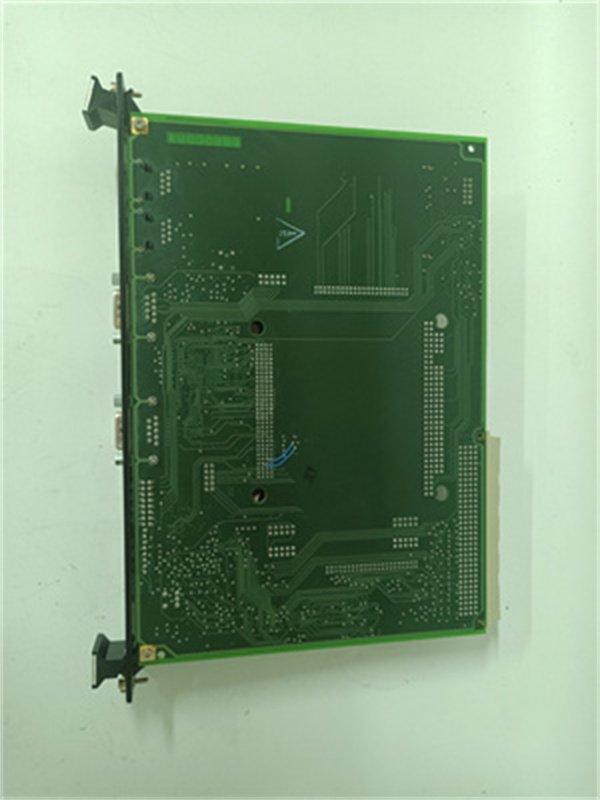

| Product model | **IS210MVRAH2A** |

| Manufacturer | GE |

| Product category | Mixed Signal I/O Module (MVRA) |

| I/O Channels | 12 analog inputs, 6 analog outputs, 16 digital I/O (8DI/8DO) |

| Input Signal Range | ±10V DC, 4-20mA, thermocouple (Type K/J) |

| Output Signal Range | ±10V DC, 4-20mA; Digital: 24V DC (sinking/sourcing) |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | ±0.1% of full scale |

GE IS215ACLEH1BB

Product introduction

The **GE IS210MVRAH2A** is a high-performance mixed signal I/O module belonging to GE’s renowned Speedtronic control system family, a platform widely trusted in power generation, industrial process control, and integrated automation systems. As a dedicated hybrid signal processing interface, the **GE IS210MVRAH2A** connects field analog sensors, digital actuators, and the main controller, enabling simultaneous accurate conversion of analog signals and reliable switching of digital signals—essential for real-time monitoring and control of complex industrial processes with both continuous and discrete variables.

Designed for industrial environments requiring integrated analog and digital signal handling, the **GE IS210MVRAH2A** integrates multi-range analog processing with robust digital switching capability. Its core functions include analog signal amplification, cold junction compensation (for thermocouples), noise filtering, digital edge detection, and high-current output driving, ensuring both raw sensor data (temperature, pressure) and discrete device status (valve on/off, pump running) are processed precisely and transmitted efficiently. In automation systems, the **GE IS210MVRAH2A** acts as a “hybrid signal hub,” eliminating the need for separate analog and digital modules, simplifying cabinet layout, and reducing inter-module communication latency.

Core advantages and technical highlights

Integrated mixed signal processing: The **GE IS210MVRAH2A** features 16-bit ADC for analog inputs and 16-bit DAC for analog outputs (±0.1% full scale accuracy), paired with 24V DC digital I/O supporting up to 0.5A per output. This hybrid design reduces system module count by 50% compared to using separate analog and digital modules, cutting rack space usage by 35%. Analog channels support automatic cold junction compensation for thermocouples, reducing temperature measurement error by 30%, while digital channels offer configurable edge detection (rising/falling) for precise event capture in discrete control.

Dual-signal fault isolation: The module incorporates channel-level fault detection for both analog and digital channels—analog overrange/short-circuit alarms and digital output overload protection. Faulty channels are isolated within 40ms, preventing cross-signal interference and system-wide disruptions. Hot-swappable capability reduces maintenance downtime by 40% in mixed-signal control systems, while its reinforced circuit design (ESD protection up to ±2kV) enhances reliability in harsh industrial electromagnetic environments. Digital outputs feature short-circuit self-recovery, eliminating the need for manual reset after transient faults.

Seamless system integration: The **GE IS210MVRAH2A** fully integrates with GE’s Speedtronic Mark VI/VIe backplanes and communicates via GE’s proprietary control protocol, ensuring synchronized analog and digital data transmission with the main controller. It synchronizes hybrid signal data with GE’s Proficy Historian for comprehensive process analysis. This compatibility allows retrofitting into existing control systems without replacing the main controller, cutting upgrade costs by 30% compared to mixed-brand analog+digital solutions. Software-configurable signal types and digital logic (AND/OR) simplify on-site commissioning.

Typical application scenarios

The **GE IS210MVRAH2A** excels in mixed-signal control applications, particularly combined cycle power plant auxiliary control, industrial boiler combustion systems, and water treatment process automation. For example, a 500MW combined cycle plant in Southern Europe faced challenges with separate analog (temperature/pressure) and digital (valve/pump) modules, leading to wiring complexity. Deploying the **GE IS210MVRAH2A** consolidated 3 modules into one, reduced wiring errors by 80%, synchronized auxiliary equipment response time by 25%, and improved plant start-up efficiency by 15%.

In a large industrial boiler system in North America, the **GE IS210MVRAH2A** integrated flame temperature (thermocouple) analog data and burner on/off digital status, enabling precise combustion control. It reduced fuel waste by 12% and annual maintenance costs by $95,000. Municipal water treatment plants use the module for pump speed (analog) and valve position (digital) control, where its hybrid signal handling and IEC 61508 SIL 2 compliance ensure process stability, translating to €110,000 in annual operational savings.

Related model recommendations

IS210MVRAH1A: Lower-channel MVRA model with 8AI/4AO/8DI/8DO, compatible with **GE IS210MVRAH2A** for small mixed-signal systems.

IS215UCSRH1A: Redundant power supply ensuring stable operation of **GE IS210MVRAH2A** in critical mixed-signal loops.

IS215UCBM01A: Backplane module expanding chassis to add multiple **GE IS210MVRAH2A** for large-scale mixed I/O needs.

IC698CPE050: GE Fanuc controller paired with **GE IS210MVRAH2A** for medium-to-large mixed-signal control.

IS210TCBH01A: Thermocouple signal booster compatible with **GE IS210MVRAH2A** for long-distance analog measurement.

IS210MVRAH3A: Higher-channel MVRA model with 16AI/8AO/24DI/24DO for ultra-large mixed-signal systems.

Proficy Machine Edition: Software for configuring mixed channels and calibrating **GE IS210MVRAH2A**.

GE IS215ACLEH1BB

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS210MVRAH2A**, power off the Speedtronic chassis and ensure the environment meets -20°C to 65°C temperature and 5-95% non-condensing humidity. Use ESD-safe tools and a torque screwdriver (0.5 N·m) for wiring—separate analog lines from digital power lines to avoid interference. Check backplane firmware (≥V4.0) and clean connectors with lint-free cloth. Configure analog signal types (voltage/current/thermocouple) and digital I/O modes (sinking/sourcing) via Proficy software before powering on, and verify digital output wiring polarity to prevent device damage.

Maintenance suggestions: Conduct monthly checks of the **GE IS210MVRAH2A**’s LED status (power, communication, analog/digital fault) and verify signal ranges. Perform semi-annual calibration of analog channels with GE’s Proficy Calibration Management software to maintain ±0.1% accuracy. For faults, use hot-swapping but ensure replacement modules have matching firmware and channel configuration. Store spares (e.g., mixed-signal terminal blocks GE P/N: 456123) in ESD packaging. Inspect digital output connections quarterly for tightness, especially for high-current loads.

Service and guarantee commitment

The **GE IS210MVRAH2A** comes with a 2-year comprehensive warranty covering manufacturing defects and mixed signal processing performance issues. GE’s global service network provides 24/7 technical support via phone, email, and online portals, with engineers specialized in hybrid control systems. Our team offers on-site commissioning, including mixed channel configuration and signal calibration, to ensure the **GE IS210MVRAH2A** delivers optimal hybrid I/O performance from installation.

Additionally, GE offers mixed signal system optimization contracts for **GE IS210MVRAH2A**, including quarterly performance audits and firmware updates. We guarantee that if analog accuracy deviates beyond ±0.1% or digital I/O fails within warranty, we provide free replacement and on-site reconfiguration. This commitment helps industrial operators streamline control systems, reduce downtime, and lower overall costs, reinforcing our role as a trusted partner in integrated automation.