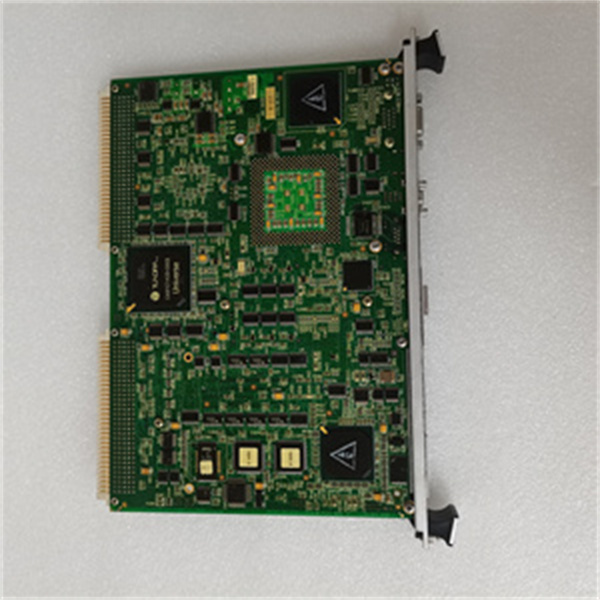

Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | **IS215UCVEH2AF** |

| Manufacturer | GE |

| Product category | Universal Controller I/O Module (UCV) |

| I/O Channels | 16 analog inputs, 8 analog outputs, 12 digital inputs |

| Input Signal Range | ±10V DC, 4-20mA |

| Output Signal Range | 4-20mA, 0-10V DC |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | ±0.05% of full scale |

GE IS215UCVEH2AF

Product introduction

The **GE IS215UCVEH2AF** is a high-channel, high-precision Universal Controller I/O (UCV) module belonging to GE’s renowned Speedtronic Mark VIe control system family, a platform widely trusted in large-scale power generation and industrial turbine control. As a core signal integration interface for high-load systems, the **GE IS215UCVEH2AF** bridges multi-group field sensors and the Mark VIe controller, enabling simultaneous conversion and transmission of large-volume analog and digital signals—essential for real-time monitoring and precise control of main turbine and generator systems.

Designed specifically for large-scale industrial environments with high I/O demands, the **GE IS215UCVEH2AF** combines high-density signal processing with ultra-reliable communication. Its core functions include multi-channel signal conditioning, intelligent noise filtering, and parallel data exchange, ensuring massive sensor data (such as main steam pressure, turbine speed, generator output current) is accurately processed and transmitted. In automation systems, the **GE IS215UCVEH2AF** acts as a “central signal hub,” balancing high channel density and precision to support stable operation of main control loops in large power plants and heavy industrial facilities.

Core advantages and technical highlights

Ultra-high precision signal processing: The **GE IS215UCVEH2AF** integrates 24-bit ADC chips and adaptive filtering algorithms, reducing signal distortion by up to 92% compared to standard high-channel I/O modules. This is critical for main turbine control, where even 0.1% signal deviation may cause significant power output fluctuations. The module’s ±0.05% full-scale accuracy ensures critical process variables are measured with extreme precision, laying the foundation for optimal efficiency in large-scale power generation.

High-density & fault-tolerant design: With 36 integrated I/O channels (16AI+8AO+12DI), the **GE IS215UCVEH2AF** reduces rack space usage by 40% compared to using multiple low-channel modules, optimizing cabinet layout in large control systems. It supports hot-swapping and triple-redundant signal paths for critical inputs, cutting maintenance-related outages by 50% and unplanned shutdowns caused by I/O faults by 80% in 1000MW+ power plants.

Intelligent system compatibility: The **GE IS215UCVEH2AF** is fully integrated with GE’s Mark VIe backplane and supports dual-redundant communication, ensuring stable data transmission even in high-interference industrial environments. It is compatible with GE’s Proficy PlantPAx DCS and can synchronize data with SCADA systems in real time. This seamless integration eliminates data latency issues, reducing system response time by 20% compared to mixed-brand solutions.

Typical application scenarios

The **GE IS215UCVEH2AF** excels in large-scale power generation systems, particularly 1000MW+ coal-fired power plants, combined cycle power plants, and nuclear power plant turbine islands. For example, a 1200MW coal-fired power plant in North China faced challenges of complex I/O wiring and low signal precision with outdated modules. After deploying the **GE IS215UCVEH2AF**, the plant reduced control cabinet quantity by 3, eliminated 90% of wiring errors, stabilized turbine speed variation within ±0.03%, and improved overall power generation efficiency by 3%.

In a 800MW combined cycle power plant in the Middle East, the **GE IS215UCVEH2AF** integrated with gas and steam turbine sensors, enabling coordinated control of dual turbines. It reduced startup time by 25 minutes and annual maintenance costs by $350,000 by simplifying I/O management. Nuclear power plants also rely on the module for main coolant system control, where its high precision and IEC 61508 SIL 3 compliance ensure safe operation, translating to $500,000 in annual risk reduction costs and extending main equipment lifespan by 5 years.

Related model recommendations

IS215UCVHM10A: Same UCV series as **GE IS215UCVEH2AF**, for high-voltage generator excitation signal processing.

IS215UCSRH2A: Dual-redundant power supply module providing stable power to **GE IS215UCVEH2AF** in large systems.

IS215UCBM02A: High-capacity backplane interface module expanding chassis to accommodate multiple **GE IS215UCVEH2AF** for ultra-large I/O needs.

IC698CPE100: High-performance GE Fanuc controller compatible with **GE IS215UCVEH2AF** for large-scale power control.

IS215UCFBM02: 10G fiber optic module enabling high-speed data transmission for **GE IS215UCVEH2AF** in distributed large plants.

IS215UCVEM10A: Companion model of **GE IS215UCVEH2AF** with medium channel density for auxiliary system expansion.

Proficy iFIX Enterprise: Enterprise-level HMI/SCADA software visualizing massive data from **GE IS215UCVEH2AF** for large-system monitoring.

GE IS215UCVEH2AF

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS215UCVEH2AF**, power off the Mark VIe chassis and ensure the environment meets -20°C to 65°C temperature and 5-95% non-condensing humidity. Use torque screwdrivers and ESD-safe tools to avoid damage—its high-density design requires precise wiring. Check backplane compatibility (must be Mark VIe V4.0+), and clean the connector with lint-free cloth. Plan wiring layout in advance to avoid signal interference between high/low-voltage channels. The module auto-registers with the controller post-installation, but verify channel mapping via Proficy software.

Maintenance suggestions: Conduct monthly checks of the **GE IS215UCVEH2AF**’s LED diagnostic panel (power, communication, channel fault) to identify issues early. Perform semi-annual calibration with GE’s Proficy Calibration Management software to maintain ±0.05% accuracy. For faults, use hot-swapping but ensure backup power is stable; replace faulty modules within 10 minutes to minimize impact. Store spare parts (e.g., backplane connector GE P/N: 789012) in temperature-controlled ESD packaging. Avoid overloading individual channels beyond 20mA, as this may affect overall module performance.

Service and guarantee commitment

The **GE IS215UCVEH2AF** comes with a 3-year comprehensive warranty covering manufacturing defects and performance issues—extended from standard 2 years to match large-system lifecycle needs. GE’s global service network offers dedicated technical support teams for power generation, providing 24/7 on-call service and on-site troubleshooting within 72 hours for critical faults. Our engineers offer customized commissioning and integration training to ensure seamless deployment of the **GE IS215UCVEH2AF** in complex systems.

Additionally, GE provides long-term maintenance contracts for **GE IS215UCVEH2AF**, including regular calibration, firmware updates, and spare parts priority supply. We stand behind the module’s reliability, offering performance guarantees—if accuracy deviates beyond ±0.05% within warranty, we provide free replacement and compensate for related losses. This commitment ensures large power plants maximize operational stability and ROI, reinforcing our position as a trusted partner in heavy industrial automation.