Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | GE IS215UCVFH2ABVI |

| Manufacturer | General Electric (GE) |

| Product Category | VME Digital I/O Module |

| Series | Mark VI Speedtronic |

| I/O Channels | 16 digital input channels + 16 digital output channels |

| Input Signal Type | 24V DC (sinking/sourcing, configurable) |

| Output Signal Type | 24V DC relay output (5A per channel, 10A per module) |

| Isolation Rating | 2kVrms (channel-to-channel, channel-to-backplane) |

| Communication Interface | Mark VI VME backplane + 1x IONet 10Base2 (BNC) |

| Operating Temperature Range | -40°C to +70°C |

| Power Supply | +5V DC (logic) / +24V DC (relay, external) |

| Installation Method | Mark VI standard VME 6U chassis slot mounting |

| Safety Certifications | CE, UL 508, IEC 61010-1 |

| Physical Size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

| Product Origin | USA |

| Warranty Period | 12 months |

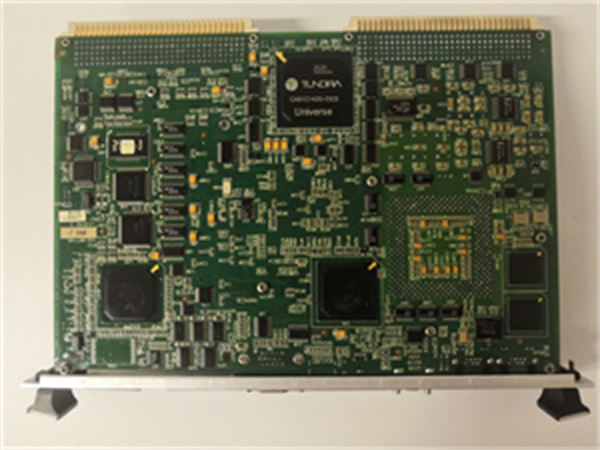

GE IS215UCVFH2ABVI

Product Introduction

The GE IS215UCVFH2ABVI is a high-density VME digital I/O module belonging to GE’s Mark VI Speedtronic series, specifically engineered for industrial control systems requiring reliable acquisition of digital status signals and precise control of discrete actuators. As a key front-end and execution component in Mark VI-based architectures, it collects digital status data from field devices (such as limit switches and sensors) and outputs relay control signals to actuators (like valves and pumps), transmitting data to/from the main controller via the VME backplane and IONet network—ensuring seamless interaction between the control system and field equipment.

Equipped with 16 configurable digital input channels and 16 relay output channels, the GE IS215UCVFH2ABVI integrates signal conditioning, isolation, and relay driving in a single module. Its input channels support both sinking and sourcing 24V DC signals, while the output channels provide 5A relay contacts for direct control of mid-power actuators. In practical applications, the GE IS215UCVFH2ABVI acts as the “execution limb” and “status detector” of the Mark VI system, enabling real-time monitoring of equipment status and accurate execution of control commands—laying the foundation for safe and efficient industrial process operation.

Core Advantages and Technical Highlights

High-Density Integrated I/O Design

The GE IS215UCVFH2ABVI features a 32-channel integrated design (16 in + 16 out) within a standard VME 6U form factor, maximizing I/O density per chassis slot and reducing system footprint. This high-density configuration is particularly valuable in space-constrained control cabinets, such as those in offshore platforms or compact turbine control rooms. Each input channel supports software-configurable sinking/sourcing modes via GE’s Proficy Machine Edition, eliminating the need for hardware jumpers and simplifying compatibility with different sensor types. The 16 relay outputs offer 5A per-channel current capacity, enabling direct control of common industrial actuators (e.g., 24V DC solenoid valves, small motors) without external contactors—reducing system complexity and cost.

Robust Isolation & Reliable Switching

The GE IS215UCVFH2ABVI incorporates 2kVrms galvanic isolation between channels and between channels and the backplane, effectively suppressing ground loops, voltage transients, and electromagnetic interference (EMI) common in industrial environments. This isolation ensures that faulty signals in one channel do not affect others, enhancing system reliability. The relay outputs use high-quality electromechanical relays with a mechanical life of over 100,000 operations and an electrical life of 10,000 operations at full load, ensuring long-term stable switching. Additionally, the module’s input circuits include surge protection (8kV ESD) and filter capacitors, preventing damage from transient voltage spikes caused by sensor wiring or nearby electrical equipment.

Seamless Mark VI Integration

Designed specifically for the Mark VI Speedtronic series, the GE IS215UCVFH2ABVI achieves plug-and-play compatibility with Mark VI VME chassis and controllers. It supports auto-discovery by the Mark VI main controller, significantly reducing commissioning time. The module’s IONet interface enables real-time data transmission with the control system, ensuring that input status updates and output control commands are executed within milliseconds—critical for time-sensitive applications like turbine auxiliary equipment sequencing. It also integrates with GE’s Proficy Machine Edition software for intuitive configuration, channel mapping, and diagnostic monitoring, providing a unified platform for system setup and maintenance.

Typical Application Scenarios

Gas Turbine Auxiliary Equipment Control

In combined-cycle power plant gas turbine systems, the GE IS215UCVFH2ABVI is deployed to control and monitor auxiliary equipment. Its 16 digital inputs connect to limit switches (e.g., fuel valve position sensors, pump running status switches) and pressure switches (e.g., lubricating oil low-pressure alarms), collecting real-time status data. The 16 relay outputs control solenoid valves (e.g., fuel supply valves, cooling water valves), auxiliary pumps, and indicator lights. When the Mark VI controller receives a “start turbine” command, it sends signals via the VME backplane to the GE IS215UCVFH2ABVI, which sequentially activates the lubricating oil pump, opens the fuel preheating valve, and monitors input status to confirm each step is completed—ensuring safe and orderly turbine startup. The module’s isolation prevents EMI from turbine generators affecting control signals.

Petrochemical Pipeline Valve Control

In petrochemical refinery pipeline systems, the GE IS215UCVFH2ABVI serves as the core digital control module for on/off valves. Its input channels connect to valve position feedback sensors (e.g., open/close limit switches) and flow switch alarms, while output channels control valve actuators. For example, during crude oil transfer, the central SCADA system sends a “open valve 3” command to the Mark VI controller, which transmits the signal to the GE IS215UCVFH2ABVI. The module activates the relay output to energize the valve actuator, then monitors the input channel to confirm the valve has reached the fully open position—sending a status feedback to the controller. If a flow switch alarm is detected (input channel triggered), the module immediately de-energizes the valve actuator to close the valve, preventing overflow. The module’s 5A relay capacity directly drives most valve actuators, eliminating the need for external contactors.

GE IS215UCVFH2ABVI

Related Model Recommendations

GE IS215VCMIH2B: A VME bus master controller that pairs with the GE IS215UCVFH2ABVI to process I/O data and execute control logic in the Mark VI system.

GE IS215VPROH2B: A communication module that works with the GE IS215UCVFH2ABVI to relay digital status data to upper-level SCADA/MES systems via Modbus TCP.

GE IS220UCSAH1A: An analog input module that complements the GE IS215UCVFH2ABVI by adding analog parameter acquisition (e.g., pressure, temperature) to the control system.

GE IS220PCAAH1A: A VME bus power supply module that provides stable +5V DC logic power to the GE IS215UCVFH2ABVI.

GE IS215UCVFH1ABVI: A predecessor model of the GE IS215UCVFH2ABVI with 8 input + 8 output channels, suitable for small-scale digital control applications.

GE IS220YDIAS1A: A supplementary digital input module with 32 channels, expanding input capacity when used with the GE IS215UCVFH2ABVI.

GE IS220TRLYH1B: A dedicated digital output module with 24 relay channels, enhancing output capacity for large-scale actuator control alongside the GE IS215UCVFH2ABVI.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS215UCVFH2ABVI, power off the Mark VI VME chassis and ensure the workspace is ESD-protected (grounded mats/wristbands). Required tools include a Phillips screwdriver, multimeter, torque wrench (0.5 N·m), and wire crimping tool. Verify the chassis slot supports VME 6U standards and prepare an external +24V DC power supply for relays. Align the module’s edge connectors with the slot guides, insert firmly until seated, and secure with front-panel screws. For wiring, use 16AWG-22AWG shielded cables for inputs/outputs; connect input signals to terminal blocks 1-16, output relays to 17-32, and external 24V DC to the power terminal. Configure input modes (sinking/sourcing) and output logic via Proficy Machine Edition before powering on the chassis and external relay power.

Maintenance Suggestions

Conduct monthly inspections of the GE IS215UCVFH2ABVI to check LED statuses (Power, Fault, Input/Output Activity) and terminal block connections—focus on relay output terminals for loose wiring or corrosion. Test input channels quarterly using a 24V DC signal generator to verify status detection, and test output relays with a multimeter to confirm contact continuity when energized. Clean the module’s ventilation slots quarterly with compressed air (≤0.5MPa). If a fault occurs, first check external 24V DC power and sensor/actuator wiring; use Proficy Machine Edition to view channel-specific diagnostic logs (e.g., short-circuit alarms on outputs). Replace with genuine GE spares (lead time 2-3 days) and reconfigure I/O parameters to match the original setup—restoring operation quickly.

Service and Guarantee Commitment

The GE IS215UCVFH2ABVI comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email and online portals, offering guidance on I/O configuration, relay troubleshooting, and system integration. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours in major industrial regions.

Extended warranty plans up to 3 years are available, including annual preventive maintenance checks and relay contact testing. GE also offers customized training on digital I/O system design and GE IS215UCVFH2ABVI integration with Mark VI systems. With decades of expertise in industrial control and discrete signal management, GE stands behind the reliability of the GE IS215UCVFH2ABVI and is committed to supporting customers throughout the product’s lifecycle.